10. Alternative form of planting: Sprigging

10. Alternative form of planting: Sprigging

First published: November 10, 2011

Written by FG Staff Writer Tony Okon

Excerpt from article:

Not everyone uses the same forms of planting. Some people might use an eight-row to 36-row planter for seed – but others might use a five-row planter for sprigging.

Yes, you read that right, sprigging. Sprigging is done by a machine that creates a trench, about 1-2 inches deep, where sprigs are deposited.

Many of you have probably heard of a sprig before, but what exactly is it? Sprigs are essentially roots with soil unattached, and they are planted in prepared soil.

Click here for the full article.

9. Bale size: Pricing and cost per unit of nutrient considerations

First published: August 7, 2012

Written by Jason Banta, a nutritionist at Texas A&M University

Excerpt from article:

Bale weight and nutrient content are critical factors in determining the value of a given bale of hay.

Bale weight affects not only the amount of hay being bought or sold but also the cost of feeding and transporting it.

An accurate assessment of nutrient content is also needed to determine the cost per pound of energy (e.g. TDN) and protein supplied.

Round bales are generally described by bale width × bale diameter or bale height. For example, a 5’ × 6’ bale would be five feet wide and six feet in diameter and a 4’ × 5’ bale would be four feet wide and five feet in diameter.

Click here for the full article.

8. Michigan producer’s baler uses air bags

First published: March 29, 2012

Written by FG Staff Ariel Waldeck

Excerpt from article:

While driving down the interstate, you may have noticed that some semi-trailers have the words “Air Ride-Equipped” on the side.

Scott Seaver of Montague, Michigan, developed a useful connection between this technology and hay baling.

“Essentially the [trailers] have air bags between the axles and the frame,” Seaver says. “It gives them a better ride because the air is compressible and it adjusts to different road conditions very quickly.”

Click here for the full article. 7. Cows weed out new forages

7. Cows weed out new forages

First published: March 29, 2012

Written by Kathy Voth of Livestock for Landscapes

Excerpt from article:

Imagine waking up tomorrow morning to find that you have 43 percent more forage, and you didn’t have to do a thing to get it.

How many more cows could you run? What would it mean to your bottom line? The good news is that this isn’t like imagining what you would do if you won the lottery.

In this case, you’ve already won and that forage is probably in your pasture right now. You’ve just been calling it “weeds.”

Economist John Morley estimates, based on average pasture weed, that if your cattle ate 70 percent of those weeds you’d have 43 percent more forage.

Click here for the full article.

6. Small steps lead to success for beginning custom harvester

First published: January 30, 2012

Written by FG Staff Emily Caldwell

Excerpt from article:

At 16 years old, Rick Jones of East Berlin, Pennsylvania, discovered his career path.

What began as an FFA project eight years ago has turned into a growing, thriving business.

It started with four acres of ground. The family used to have another harvester bale the hay, and Jones asked his father if they could do it themselves.

The father-son team borrowed equipment from other local farmers and gave it a try.

“That same year, another person wanted us to bale their hay, so that was the first job we ever had,” Jones says.

“Ever since, it’s just been steadily growing. That first year, we did 400 bales. This past year, we did 27,000. It’s grown a lot more than we ever figured it would.”

Click here for the full article.

5. Corn shredlage for dairy cows

First published: May 10, 2012

Written by Luiz Ferraretto, Student of Dairy Nutrition at the University of Wisconsin and Randy Shaver, part of the Department of Dairy Science at the University of Wisconsin – Madison Extension

Excerpt from article:

Garnering much recent interest by dairy producers and their nutritionists has been a new method of harvesting whole-plant corn for silage.

The resultant product has been called corn shredlage* by the developer of the process (Shredlage™ LLC) and the manufacturer of the new processing rolls used in the process.

Click here for the full article. 4. Teff grass – Quality forage, fast

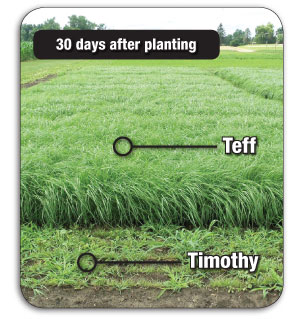

4. Teff grass – Quality forage, fast

First published: November 10, 2011

Written by Donald R. Miller, director of product development at Producer’s Choice

Excerpt from article:

Teff grass is a summer annual forage for livestock and commercial hay producers who often need a fast-growing, high-yielding crop with competitive forage quality.

Teff has a wide range of adaptation and is being used all across the U.S. as hay, silage or pasture for dairy, beef, sheep or horses.

The emerging popularity of teff has been driven by its ability to produce high-quality hay in a relatively short growing season with relatively low inputs (average nitrogen requirements per season are 30 to 60 units).

Click here for the full article.

3. A bit about hay carriers

First published: March 28, 2012

Written by Dennis McGrew and Doug DeShazer; from a North American Hay Tool Collectors Association newsletter

Excerpt from article:

Getting the hay crop in the mow

Putting up hay in the mid-1800s was both time and labor-intensive. When the crop was in blossom at its peak food value, it would be cut by men swinging giant swaths with their scythes.

After drying in the sun it would be raked by hand into small piles or gathered into haycocks by “sweeps” pulled by horses. From there it was forked onto a wagon and then forked again into the barn loft.

With the advent of horse-drawn mowers – cutting a swath of usually three or four, sometimes up to six feet at a time – haymaking took a big turn. Hay loaders were developed by the 1870s and dump rakes dragged the hay into crude windrows.

Click here for the full article.

2. Storage of small square bales

First published: May 11, 2012

Written by John W. Worley, associate professor at University of Georgia Cooperative Extension

Excerpt from article:

When I was growing up in the ’60s, there was little choice about how to store hay.

It was virtually all stored in small square bales and much of it was stored in a barn loft.

With the advent of large round balers, large square balers and hay wrappers, producers now have a multitude of choices on how to store their hay, but the small square bale still has a strong place in the marketplace.

For horses, show animals and owners of small numbers of animals, it’s hard to beat the convenience of packaging hay in a form that can be handled by one person.

Click here for the full article. 1. Winners of the 2011 Hay Bale Decorating Contest

1. Winners of the 2011 Hay Bale Decorating Contest

First published: December 2, 2011

Written by FG Editor Lynn Olsen

Excerpt from article:

We had some wonderful entries for the 2nd annual Progressive Forage Grower Hay Bale Decorating Contest, but after the votes have been tallied, we have our top three winners!

First prize goes to Jill and Kevin Weber from Hopkinton, Iowa, for their bride and groom.

Click here for the full article. FG