After all, a lot of time, energy and expense have gone into producing a high-quality and high-value baled product.

Many would argue correctly that expensive storage options aren’t necessary, but make sure to consider all your expenses.

Storage losses have a big effect on hay quantities and quality, so in the long run investing additional resources (money, labor, equipment) in hay storage could pay big dividends.

To put storage losses in perspective, let’s assume you store your hay outside and have a fairly reasonable storage loss of 10 percent.

That may not sound all that bad, but a 10 percent storage loss means that for every 10 bales of hay that you harvest, you really only have the equivalent of nine bales of hay to feed.

What are my bale storage options?

Storage options vary, but typical choices may include:

- under roof

- outside uncovered on the ground or elevated

- outside covered on the ground or elevated

- bale sleeve on the ground

- net wrap on the ground

- plastic wrap on the ground

How does dry matter loss compare between storage options?

First, it’s worth noting that if dry matter loss was the only factor to consider, hay storage under a roof would be an easy top choice.

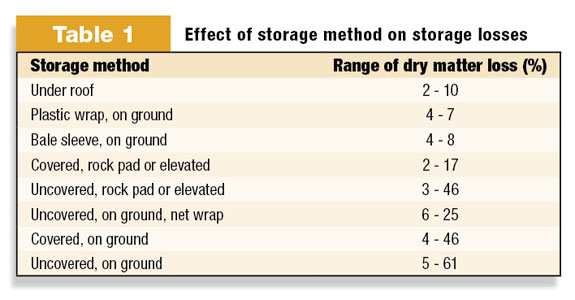

Table 1 gives general dry matter losses for various storage methods. The wide range in dry matter loss emphasizes the variability found between individual trials and handling procedures in both dry and humid climates.

Ultimately, dry matter loss is a function of hay moisture, temperature and the length of time hay is exposed to these conditions.

Large losses can occur in a short timeframe under high-moisture and temperature conditions. However, you can end up with similar losses by storing a dry product in a cool barn for an extended period of time.

How can I minimize dry matter losses?

Minimizing dry matter loss starts by storing your hay on the best well-drained surface you have available. Bales will absorb moisture from the soil if left outside on the moist ground.

The wetter the soil, the more moisture bales will absorb. Even when covered by plastic tarps, contact with moist soil increases dry matter loss compared to bales not coming in contact with the soil.

If possible, elevate the bales to break the soil moisture’s wicking action by using a pad of large crushed rock or some other product (concrete, pallets, old tires, etc.).

If storing bales unprotected, strive to make larger bales that have less surface exposure to the elements as compared to smaller-sized bales.

Also, densely packed bales shed more moisture than low-density bales. Less damage occurs if round bales are stacked end to end.

Net wrapping does not eliminate the problem, but helps bales shed precipitation better than those wrapped with twine. Bales made from flat, grassy forage shed water better than coarse, stemmy alfalfa.

Placing bales in a sunny area helps to keep them drier than if they are stored under a shade tree. Store bales so runoff passes between rows of bales (up and down hill) instead of at the bales (on the contour).

Unprotected bales should not be stacked, as this prevents water from running away and keeps the bales from drying out. Lastly, remember that bales stored outside should be used or sold as soon as possible.

What is the best hay storage option?

It should be emphasized that forages stored as big bales benefit from some form of protection. It would be unrealistic to say that one option is better than another.

Individual farms should analyze each option and decide which works best for them. Factors like the availability and cost of labor and machinery and the location of hay fields, storage sites and feeding sites all play an important role in determining the best storage option.

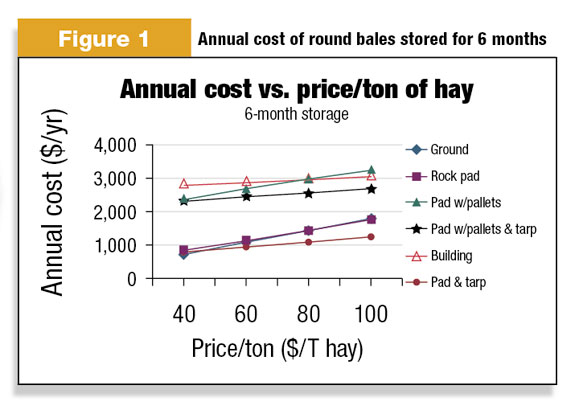

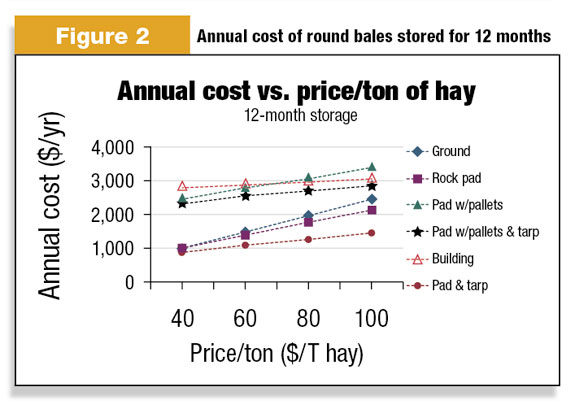

Figures 1 and 2 show an example set of assumptions by Brian Holmes, professor and extension specialist – University of Wisconsin.

Using these numbers, Holmes found that the lowest-cost alternative in both six-month and 12-month storage systems was the use of a crushed rock pad with a tarp covering, but remember the results of this analysis were affected by the assumptions used.

In this example analysis, storage options were designed around handling 378 round bales weighing 1,200 pounds per bale.

Building costs were based on new construction costs. Understandably, building costs will vary based upon size and type of construction.

Annual costs included average dry matter losses in a humid climate. How you make round bales and in what type of weather conditions (moisture and temperature) will also affect dry matter losses.

The take-home message – consider using your own set of assumptions to determine a storage system that’s right for you.

If you would like to analyze round bale storage costs further, the Excel spreadsheet titled “Cost of Forage Storage Spreadsheet Documentation” used for these calculations can be downloaded at. FG

References omitted due to space but are available upon request.

—Excerpts from University of Wisconsin Extension newsletter

PHOTO

Hay is protected in a covered barn to maintain quality over an extended storage time. Photo courtesy of Ed Rayburn.

Craig Saxe

Agriculture Extension

University of Wisconsin