We reached out to the authors and participants of each article for further comment; here is what we heard back, along with a summary of each article.

1. Walker Farms diversifies with a new processing plant, dairy bar

Published May 2021

Earlier this spring, Walker Farms in Aylmer, Ontario, announced their expansion of an on-site processing plant and dairy bar. True to generations past, Scott Walker, dairy operations manager, shared their family’s strategy for continued growth in the ever-changing dairy industry.

Stemming from pressures on Canada’s supply management system and trade deals, Walker Farms decided to diversify. The idea to process their own milk began five years ago, at which point they began breeding for the A2 beta-casein gene, to give them a competitive advantage. Long-term goals include product development and the ability to meet future consumer demand by processing all milk on-site. (Current processing capacity is 25,000 litres per day – half of the farms’ total milk production.) Walker Farms processes 1%, 2% and 3.25% white milk and 2% chocolate milk, which can be purchased at their new Walker Dairy Bar (as well as many other local products) and at local farm markets and grocery stores.

How have things been running since your dairy bar and processing plant have become fully operational?

“Since opening in June, both the Walker Dairy Bar and the Walker Farms milk processing plant have been running smoothly. The dairy bar initially only offered a drive-through service, but with businesses opening up and COVID-19 restrictions easing up, customers are now able to enter the storefront as well. The dairy bar offers a variety of Shaw’s ice cream, specialty coffee and snacks, but the big seller is our Walker Farms milk. The decision to have a location within the town of Aylmer where customers can purchase the milk, instead of building a store at the farm, has allowed for more traffic to the store while still offering a great ‘buy local’ experience.

“Walker Farms milk can also now be found in almost 70 stores across Ontario. Introducing a new product into the dairy aisle has been an uphill battle, but the customer base is growing, and it’s been great working with grocery stores and markets across southwestern Ontario.

“Increasing awareness about the benefits of A2A2 milk has been our biggest challenge – consumers are still unaware of the product. It’s been great receiving feedback from people who have shied away from regular milk for years, who are now able to drink our milk. We pride ourselves on offering a product that allows for more consumers to drink cows’ milk instead of turning to a milk alternative.

“Our plan is to continue to grow the existing business and increase awareness of the Walker Farms brand. We will continue to explore new dairy product innovations and hope to work with industry partners to increase consumption of dairy products across the province.”

Read the full story at Walker Farms diversifies with a new processing plant, dairy bar

—Pam Emmott, director of sales and marketing, Walker Dairy

PHOTO: As COVID-19 restrictions ease, Walker Dairy Bar has shifted from offering drive-through service only to allowing customers to enter the Aylmer, Ontario store. Photo courtesy of Walker Farms.

2. fairlife opens Ontario plant with 100% Canadian milk

Published January 2021

As originally reported in the April 2019 issue of Progressive Dairy, fairlife entered the Canadian market announcing the construction of a $85 million processing plant in Peterborough, Ontario, with their plan to use milk sourced from Canadian dairy farms. In September 2020, this became a reality, and the facility opened using 100% Canadian dairy.

The facility processes 1.5-litre ultrafiltered 2% white and 2% chocolate, whole and skim milk, using their patented cold-filtration system, offering the benefit of 50% less sugar and 50% more protein, in addition to being lactose-free and nutrient-rich milk. Due to growing consumer demand in the value-added dairy category, fairlife stated they left room for growth at the plant with plans for continued product innovation, job creation and expansion into Quebec and the Maritimes.

What updates do you have to share after one year of processing milk solely sourced from Canadian dairy farms?

“fairlife has seen continued growth in Canada since we opened our Peterborough facility in 2020, and we are pleased to have been producing and selling 100% Canadian milk for over one full year now, with the Dairy Farmers of Canada Blue Cow logo proudly displayed on all our Canadian products.

“We are continuing our efforts to discover areas for growth for dairy across Canada, and that includes our re-entry into Quebec earlier this year. The value-added dairy category continues to expand, and it is up to us to continue to meet the demands and preferences of Canadian consumers. We believe the high quality of the milk in Canada we use to produce our dairy products, along with keeping an eye on possibilities for innovation and further expansion, will allow us to continue to recruit Canadian consumers and grow the category. While no effort as vast as the one we’ve undertaken in Canada goes without its challenges, we are proud of our employees for their commitment and grateful to our partners across the Canadian dairy industry for their collaboration.”

PHOTO: Photo courtesy of fairlife Canada.

Read the full story at fairlife opens Ontario plant with 100% Canadian milk

—Ryan Denys, North American dairy lead, The Coca-Cola Company

3. 5 hoof-trimming chute must-haves

Published October 2020

Seasoned hoof trimmers Raymond Boulais, Gaston Fournier and Jamie Sullivan trim thousands of cows a year. Each uses a different brand of hoof-trimming chute, but they agree there are five essential features any farm should look for before purchasing a hoof-trimming chute for in-house trimming.

Their five hoof-trimming chute must-haves are: hydraulic components, elements that ensure comfort for the trimmer and cow alike, leg restraints, animal supports and compactness.

What skills should be reviewed regularly to avoid bad habits and maintain a safe and effective in-house hoof-trimming program?

“A successful in-house trimming program comes down to three key areas:

1. Training and continued education. It’s important to have a regular refresher on your trimming techniques. I offer my students a day refresher either in a one-on-one at their farm or with a few past students for a trim day to review and evaluate trimming techniques.

2. Trim area and equipment maintenance. Like other farm equipment, it’s important to have a scheduled maintenance program for your hoof-trimming chute. Make sure the leg rope and belly bands are in good condition. It’s also important to maintain sharp hoof knives and trimming wheels to be able to achieve a proper trim and perform the task safely.

3. Time management and records. Just like herd health is usually a scheduled task, it’s important to do the same with your in-house trimming program. Whether that is a daily schedule to do a few cows or a weekly half or full day. Like everything, there needs to be a record of when cows were trimmed and the results. Set goals, monitor and review hoof records.”

—Jamie Sullivan, hoof trimmer, Rippleview Hoof Care

“First off, producers need to recognize the severity of lameness. This begins with checking cows twice a week, or ideally once a day, for signs of lameness immediately after they pass through a footbath. Farms should dedicate one day a week to trimming, much like they would with nutrition or herd health. Each cow should have its own trimming schedule, and I think the ideal interval for this is at 100 days of lactation and then again at 250 days lactation. Producers must periodically review and assess their trimming technique through continued training and discussions with industry experts. To evaluate herd hoof health, producers should record all anomalies and compare performance with previous records from their own herd and with records from other dairies. It is important that farms maintain a treatment protocol established in accordance with their herd veterinarian.

“In conclusion, lameness detection and awareness, time management, training, protocol implementation, teamwork and consistency are key to success. Seeking assistance from an experienced, professional hoof trimmer can help ensure regular trimming is achieved. With all these factors in place, it is possible to attain zero lameness.”

PHOTO: A hoof-trimming chute with minimal moving parts will help reduce maintenance needs, says hoof trimmer Jamie Sullivan. Photo by Jamie Sullivan.

Read the full story at 5 hoof-trimming chute must-haves

—Raymond Boulais, hoof trimmer, La Sabotière

4. Can canola meal benefit early lactation cows?

Published March 2021

Two major feeding trials revealed canola meal brings value when fed to cows in early lactation. In the first experiment, cows fed canola meal as part of the ration from calving through 16 weeks of lactation had great milk yields and improved feed efficiency compared to those fed the same amount of soybean meal. The second study compared a diet with canola meal to one with half canola meal and half soybean meal to a third treatment with the split meal and extra rumen-protected methionine. Milk yield was greatest for the diet that contained the most canola meal.

Based on this research, what would your recommendation be when formulating early lactation diets?

“Canola meal should be strongly considered as a protein source for early lactation cows for several reasons:

- Numerous research trials and early lactation trials have demonstrated that canola meal supports greater dry matter intake (DMI), energy intake and milk yields.

- Canola meal provides as much escape protein as soybean meal on a per-kilogram basis, and the amino acid profile is closer to the cow’s needs for milk synthesis.

- Because of the excellent amino acid profile, canola meal protein is used efficiently. This can be critical in early lactation.

- The high efficiency of use of canola meal protein results in less milk urea nitrogen (MUN).

- Don’t be afraid to use more canola meal in early lactation. Great results were seen in both experiments when canola meal inclusion was beyond 10% of the diet.”

—Brittany Dyck, senior manager, canola utilization, Canola Council of Canada; and Essi Evans, dairy nutritionist, Technical Advisory Services Inc.

Read the full story at Can canola meal benefit early lactation cows?

PHOTO: Photo courtesy of Canola Council of Canada.

5. 14 common hoof and leg issues that can lead to lameness

Published February 2021

There’s more to lameness than what meets the eye. Often, an underlying root cause may be environmental (including hygiene and housing), injury, genetics, lactation stage, nutrition or related to hoof-trimming maintenance. Further, it’s important to differentiate contagious from non-contagious lesions so the correct and most effective preventative and therapeutic protocols can be enacted.

Of the 14 hoof and leg lesions you identified, which do you believe has the greatest opportunity for dairy farmers to make progress?

“I believe that out of the 14 hoof and leg issues identified, the greatest opportunity for dairy farmers to make progress is to get digital dermatitis under control. With the right commitment to maintain a hoof-trimming program, practice of biosecurity, good standards of hygiene and a tailored footbath program (along with addressing any hoof issues that arise immediately), this issue can be minimized to increase overall herd productivity.”

Read the full story at 14 common hoof and leg issues that can lead to lameness

—Kayla Pecora, agriculture specialist, FloChem Ltd.

6. A new barn ushers in a new breeding philosophy for Robella Holsteins

Published May 2021

To avoid exiting the industry, Kenton Lindenbach, owner of the Balgonie, Saskatchewan dairy Robella Holsteins, decided to take the leap to upgrade the farm’s aging facilities and continue his family’s hands-on management approach.

Robella Holsteins finished construction on their new barn in February 2020. The barn is equipped with features like two milking robots, sand bedding, perimeter feeding and an automated feed pusher and alley vacuum scraper. Along with the new build, they increased their herd size from 66 to 100 milking cows.

The farm’s upgrades have facilitated some of the changes to their breeding philosophy. In anticipation of their new barn, the farm has spent the last few years transitioning to sexed semen, increasing their heifer population and even crossing some cows with beef genetics.

With many shows slated to return in 2022, how are you leveraging your facility upgrades to prepare

for these events?

“We are excited to put our facility to use in preparation for the upcoming show seasons. In our new facility, we designed a designated area specifically to meet the individual needs of our show cows. We have an area with eight sand stalls behind the robot for show cows. They can access the robot when not prepping for show season. We also installed a pipeline milking system that allows us to milk them twice daily prior to going to shows. This saves us time and allows us to be more hands-on with our show cows compared with giving them access to a robot only twice daily.

“With our show cows being separated from the herd, we can component feed them individually, which is different from access to PMR all day as the rest of our herd has. The new barn allows us to wash our show cows year-round, as it has better climate control and ventilation. There are no concerns with the cows getting too cold or over access to warm water in the new facility for washing.

“Beyond these benefits provided by our new facility, we also renovated our old tiestall barn to house our heifers. This has allowed us much more flexibility in growing our heifers and prepping them for shows. We can house smaller groups due to more space and really focus on their individual needs, both during post-weaning and prepping for shows. I see big things in Robella Holsteins’ future with what our new and updated facilities offer us.”

PHOTO: Robella Holsteins at this year’s Westerner Dairy Showcase held in Red Deer, Alberta, where they placed first in the Junior Breeders’ Herd class. Photo provided by Kenton Lindenbach.

Read the full story at A new barn ushers in a new breeding philosophy for Robella Holsteins

—Kenton and Alicia Lindenbach, dairy producers, Robella Holsteins

7. The future of dairy in Canada

Published in February 2021

On Jan. 7, four panelists convened at Grey Bruce Farmer’s Week to discuss the future of Canada’s dairy industry. Representing different sectors of the industry, Mark Hamel, Michael Barrett, Bruce Muirhead and Vern Osborne laid out their expectations for the industry’s future.

The panelists identified three major issues facing Canadian dairy: trade agreements, consumer demands for sustainability and the challenges of innovation and competition.

The panel concluded that while many challenges are ahead for Canada’s dairy sector, there is still good reason to be optimistic regarding the longevity and stability of the industry.

As we approach the end of another year, what is your outlook for Canadian dairy entering 2022?

“The strength of our Canadian dairy system has proven itself both through the pandemic and in the recovery phase. Ontario producers were counted on to deliver high-quality milk through some challenging times. They took their responsibility to nourish Canadians seriously, and they delivered.

“Looking ahead to 2022, the ability to grow production at farm and processor level continues to be a challenge. A coordinated approach is required across the country to encourage processor capacity, efficiency and innovation. This doesn’t just mean innovation in terms of products and packaging, but in terms of policies as well. Investments need to happen in regions where it makes the most economic sense. As stakeholders in the Canadian dairy industry and P10, we share the risks as well as the opportunities, so a clear, unified vision is critical for future success.

“Sustainability in dairy is also a priority in the coming year, and we need to define our goals and commit resources. This is a journey that begins today with each of us, and it must become part of our DNA as an industry.”

Read the full story at The future of dairy in Canada

—Mark Hamel, board member, region 11, Dairy Farmers of Ontario

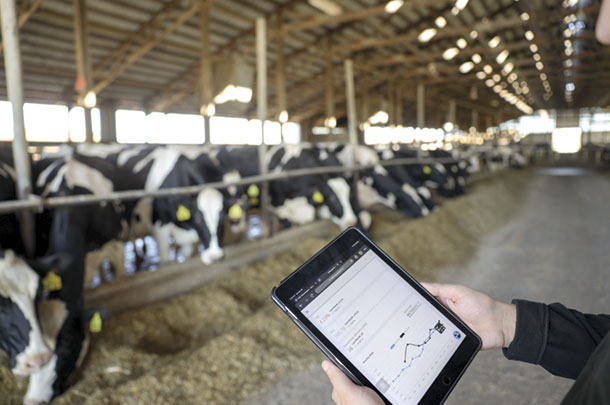

8. Software system digitizes and optimizes the dairy supply chain

Published June 2021

Milk Moovement, a cloud-based software, connects members of the dairy supply chain with a single shared database. It starts with the driver mobile app that provides real-time pick-up and drop-off data, route planning and an easy-to-use interface. The driver app’s route data is integrated with lab and third-party data, which is all stored in shared portals. Producers, cooperatives, processors and haulers can each access a portal customized just for them to digitize and optimize operations, view real-time information, understand historical trends, set custom notifications and predict and resolve supply chain problems in minutes.

What new features or coverage areas have you introduced since the article was published?

“Milk Moovement has been going through non-stop growth. We’ve been expanding quickly into the U.S. market this year, signing co-ops like California Dairies Inc. and United Dairymen of Arizona. In Canada, we’ve expanded our team to around 40 employees who have been working to tailor our cloud-based software to our customers’ needs. Recently, we’ve introduced an updated driver scheduling feature, and we’re currently working on our app notifications after receiving some feedback from our users. We are excited to continue providing constant improvement to our technology so our customers can have actionable intelligence across their entire supply chain.”

PHOTO: Milk Moovement provides producers, cooperatives, processors and haulers access to a portal customized just for them to digitize and optimize operations, view real-time information, understand historical trends, set custom notifications, and predict and resolve supply chain problems in minutes. Photo courtesy of Milk Moovement.

Read the full story at Software system digitizes and optimizes the dairy supply chain

—Katherine Alexander, marketing lead, Milk Moovement

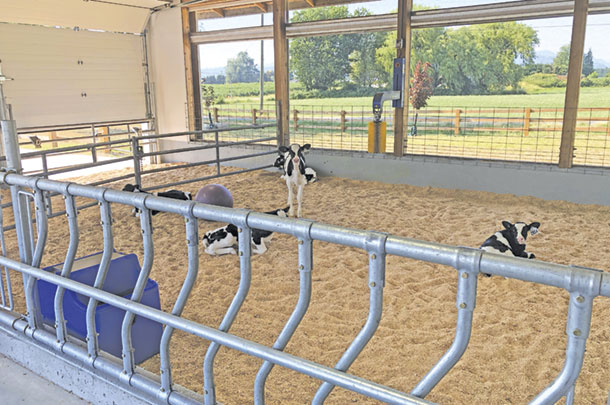

9. Prime Acres Ltd. trusts manure separator and calf facility to attain its goals

Published July 2021

After installing a manure separator five years ago to reduce sawdust bedding costs, Casey Pruim said his farm, Prime Acres Ltd., observed improvements in cow comfort and nutrient management as well as increased manure storage.

To follow the success of the farm’s switch to recycled manure bedding, Prime Acres made another big change to achieve Pruim’s long-held goal of raising calves using automated feeding. Before implementing the new feeding system, Pruim wanted to build a calf facility and spent years searching for the perfect ventilation system, settling on automated temperature-controlled curtain sidewalls and a positive-pressure tube. His new calf facility has provided the farm with major labour savings and created a more pleasant work environment.

Pruim credits much of the ongoing success of his calf housing facility to its ventilation system and recommended other producers considering a facility upgrade commit to investing in proper ventilation.

How do you measure the success of calf care, health and growth in your new calf housing facility?

“We are part of a benchmarking program through our vet clinic. A veterinary technician comes in every Tuesday morning and weighs all the calves born that week, as well as any calves in their eighth week of life to chart average daily gain (ADG) and track weaning weights. The calves are also blood-sampled to measure passive transfer of colostrum, and the information is entered in our DairyComp herd management software. Any treatments for scours or pneumonia are recorded and tracked in DairyComp.

“By recording and charting this information, together with genomic information, we can make decisions about animals that may need to be culled and look for trends in calf-raising data to help make management decisions moving forward.”

PHOTO: Following the advice of the latest research he has seen, Casey Pruim hopes automated feeding in his new calf housing facility will translate to increased milk production down the line. Photo provided by Casey Pruim.

Read the full story at Prime Acres Ltd. trusts manure separator and calf facility to attain its goals

—Casey Pruim, dairy producer, Prime Acres Ltd.

10. Fine-tuning dry cow Goldilocks diets

Published October 2020

The Goldilocks dry cow diet was developed to balance nutrient intake for the pregnant cow, the unborn calf and colostrum synthesis. It offers the right level of energy for a targeted dry matter intake (DMI). This article covers several factors that impact the success of this diet in a dry cow program, such as processing of the straw, target body condition scores and amino acid requirements.

What do you like about the Goldilocks diet as an option for feeding dry cows?

“The low-energy diet (Goldilocks diet) allows dry cows free-choice and optimal dry matter intake at 12.5 to 13.5 kilograms per day, which is a benefit after calving to achieve optimal dry matter intake (DMI) in the fresh cow pen. Because the energy level is low, bodyweight gain or body condition scores remain constant, avoiding fat cow risks. Since wheat straw, grass hay and corn silage are low in soluble and crude protein (CP), we can better control the levels of supplemental and metabolizable protein. For instance, urea can be an economical nitrogen source that improves fibre digestibility, while canola or soybean provide key amino acids. In the close-up diet, we increase energy, metabolizable protein (MP), add a calcium additive to improve blood calcium and additives such as chromium and rumen-protected choline using the low-energy diet approach. The cost of these diets can be competitive due to high forage levels.”

Read the full story at Fine-tuning dry cow Goldilocks diets

—Mike Hutjens, professor of animal sciences emeritus, University of Illinois – Urbana

11. Cuddling your calves with care: The first 24 hours

Published July 2021

Newborn calves need to be dry, warm and clean to keep them healthy and set them up for success. A cuddle box, incubator, calf transporter and calf jackets can be helpful tools in accomplishing this mission.

What is one aspect of newborn care that is often overlooked and why is it essential to calf health?

“The first 24 hours are often overlooked. What you do during this period will predict a calf’s future productivity. You need to focus on colostrum management. Getting clean, high-quality colostrum into the calf as soon as possible is by far the most important step to ensure the calf thrives.

“Every detail is important, from calving to moving and transporting the calf to its next location. The calf must be clean, warm and dry. Be accountable for this process. Continue to monitor the effectiveness of your calf management program through data analysis (colostrum quality testing, monitoring passive transfer, average daily gains, disease events and treatment rates).”

PHOTO: A cuddle box and calf transporter function as two tools in one. Photo by Jodi Wallace.

Read the full story at Cuddling your calves with care: The first 24 hours

—Jodi Wallace, veterinarian, Ormstown Veterinary Hospital

12. All fatty acids are not alike: Meet oleic acid

Published January 2021

Oleic acid has some unique attributes compared to other major fatty acids found in dairy feeds. It has the highest potential to escape the rumen, the highest intestinal digestibility and the least likely unsaturated fatty acid to reduce milkfat. It can also reduce greenhouse gas methane. Fatty acids from canola meal and sunflower meal provide the greatest amounts of oleic acid.

When might it be beneficial to do a fatty acid analysis of a dairy’s feed ration?

“Fatty acid analyses can be costly, and therefore judicious use is advised. There are tabular values providing fatty acid profiles for the most common feed ingredients. What can be variable is the fatty acid composition of ingredients and, in particular, some byproduct ingredients, such as food residues, brewery waste and distillery waste. An unexpected increase in the fat content of the diet can result in changes in milkfat and off flavour. Fatty acid analysis should be conducted for any ingredients where the fatty acid composition is not known, particularly if the ingredients contain more than a couple of percentages of fat and/or will become a major part of the ration.”

Read the full story at All fatty acids are not alike: Meet oleic acid

—Brittany Dyck, senior manager, canola utilization, Canola Council of Canada; and Essi Evans, dairy nutritionist, Technical Advisory Services Inc.

13. Lone Pine Jerseys focuses on winning management philosophy, connecting with consumers

Published August 2021

Three generations of family members are behind the success of Jersey Canada’s 2021 Master Breeder award winners, Lone Pine Jerseys. Since purchasing the farm in 1993, Adrian Haeni’s family has focused on breeding reliable commercial cows.

Their management philosophy focuses on cow longevity. To do so, they rely on tools like A.I., sexed semen and due diligence, as well as close management of each cow starting at birth.

This summer, the farm broke ground on the construction of their new on-farm processing facility. Their goal is to market their products locally and connect with their consumers, something they also achieve via their Facebook page.

Haeni’s eldest son, Michael, shares videos of the farm’s day-to-day operations with over 4,500 followers. His aim is to improve consumer perceptions of the industry.

How is construction on your processing facility progressing?

“Since our interview, we are further into the construction process but not as far as we would like to be. The foundation is poured, and the cement work is all done, and we are almost ready to put up the walls and rafters, and then things shouldn’t take too long once those are up. It will be a winter project to get it all done, but with harvest, a sale and a show, things got prolonged a little bit. However, we are still hoping to open the facility and go into production later this winter or in early spring.”

PHOTO: The Haenis have been breeding and raising Jerseys since they immigrated to Canada in 1993 and recently earned the title of Master Breeder from Jersey Canada. Photo provided by Michael Haeni.

Read the full story at Lone Pine Jerseys focuses on winning management philosophy, connecting with consumers

—Adrian Haeni, dairy producer, Lone Pine Jerseys

14. Ridge options for natural ventilation systems

Published January 2021

In naturally ventilated barns, there are three main options for ridge ventilation systems: open ridge, overshot ridge and ridge chimney. The best option for a barn depends on factors such as presence of wind, whether or not the barn has a ceiling, how the ridge will function with the sidewall system and options for automated control. Ultimately, the goal of the entire system is to provide comprehensive, complete year-round ventilation and a healthy cow environment.

What ridge option do you most commonly see on new construction projects?

“Our experience over the last 10 to 15 years is that the ridge chimney system is being used in a high percentage of new dairy construction.”

PHOTO: A ridge chimney does not rely on the presence of wind. Rather, it uses the temperature difference inside the building to exhaust air from the building. Photo courtesy of Faromor.

Read the full story at Ridge options for natural ventilation systems

—Rick McBay, natural ventilation specialist, Faromor

15. What happened? What’s next? – Concerns over hard butter leads to formation of industry working group

Published March 2021

A social media firestorm questioned a change in the characteristics of butter. It was felt the hardness of butter had increased. Some people blamed winter, the colder weather and colder room temperatures. Another theory was that, due to the pandemic and closures, lower-grade butter was diverted from food service outlets to retail stores. The reason that garnered the most attention was speculation into the use of palmitic acid supplements, a byproduct of palm oil, as a feed ingredient for dairy cows. In response, Dairy Farmers of Canada (DFC) announced the formation of a working group comprised of stakeholders and experts to assess current literature, gaps in data and look into issues that have been raised by consumers. While the group of experts seeks fact-based explanations, DFC also asked dairy farmers to consider alternatives to palm supplements.

What progress has the working group made to date?

“Last February, in response to reports from media and consumers that raised questions about the consistency of butter and the use of animal feed supplements containing palm byproducts, an Expert Working Group was put in place to assess these reports and develop fact-based explanations to these questions.

“The Expert Working Group includes prominent academics and experts from across Canada, with a diverse range of expertise. All are recognized as leaders in their fields, with specializations in areas such as dairy nutrition, animal health, sustainability, food science, and human nutrition. The group also includes representation from the Consumers’ Association of Canada, as well as participation from dairy processors and farm-level experts.

“The group met six times from March to November and received presentations and reports from discussions with several outside experts. The report from the Expert Working Group was being finalized in mid-November, will be translated and then released.”

Getty Images.

Read the full story at What happened? What’s next? – Concerns over hard butter leads to formation of industry working group

—Statement from the Expert Working Group on Feed Supplementation in Dairy. ![]()