Sustainable manure management is all about continual improvement. Where you are today is not as important as where you are going. But how do you get there?

Manure storage and handling does and will continue to play a major role in dairy farm sustainability and the ability to achieve carbon-neutral goals. Technology in this sector is rapidly changing, with new equipment and opportunities for increased sustainability continually coming to market. It can be difficult to decide where to start or what will be a good long-term investment.

Consider these tips to help you prepare for the future and determine what changes you can make today that will help you get one step closer to your sustainability goals.

Consider equipment lifespan

The longevity of your manure equipment plays a role in sustainability. From a manufacturing perspective, high-quality, long-lasting equipment means fewer natural resources are needed to replace existing parts and products.

When choosing manure equipment, consider the technology's expected lifespan and maintenance requirements. Some manure equipment companies are switching to stainless steel over mild steel, which tends to deteriorate in five to 10 years. Stainless steel equipment lasts longer while also using fewer natural resources. Another option is modularly designed equipment for easy maintenance. Replacing only one small part as needed is more sustainable than replacing the entire system.

From an on-farm perspective, with greater longevity and efficiency of your equipment, you are using fewer inputs to run it, creating more efficient outputs and reducing the overall maintenance needs.

And it is not always about buying the newest equipment. For example, one farm I have worked with has used the same manure pumps for over 20 years, pumping over 1 billion gallons of manure to a digester nearly trouble-free. Can you get the same longevity and efficiency from your manure equipment?

Look for options to extend the life and efficiency of your current manure equipment. For instance, automated cleaning options for your manure separation equipment can help that equipment work more efficiently, reduce waste and lower the environmental impact.

Focus on full-circle opportunities

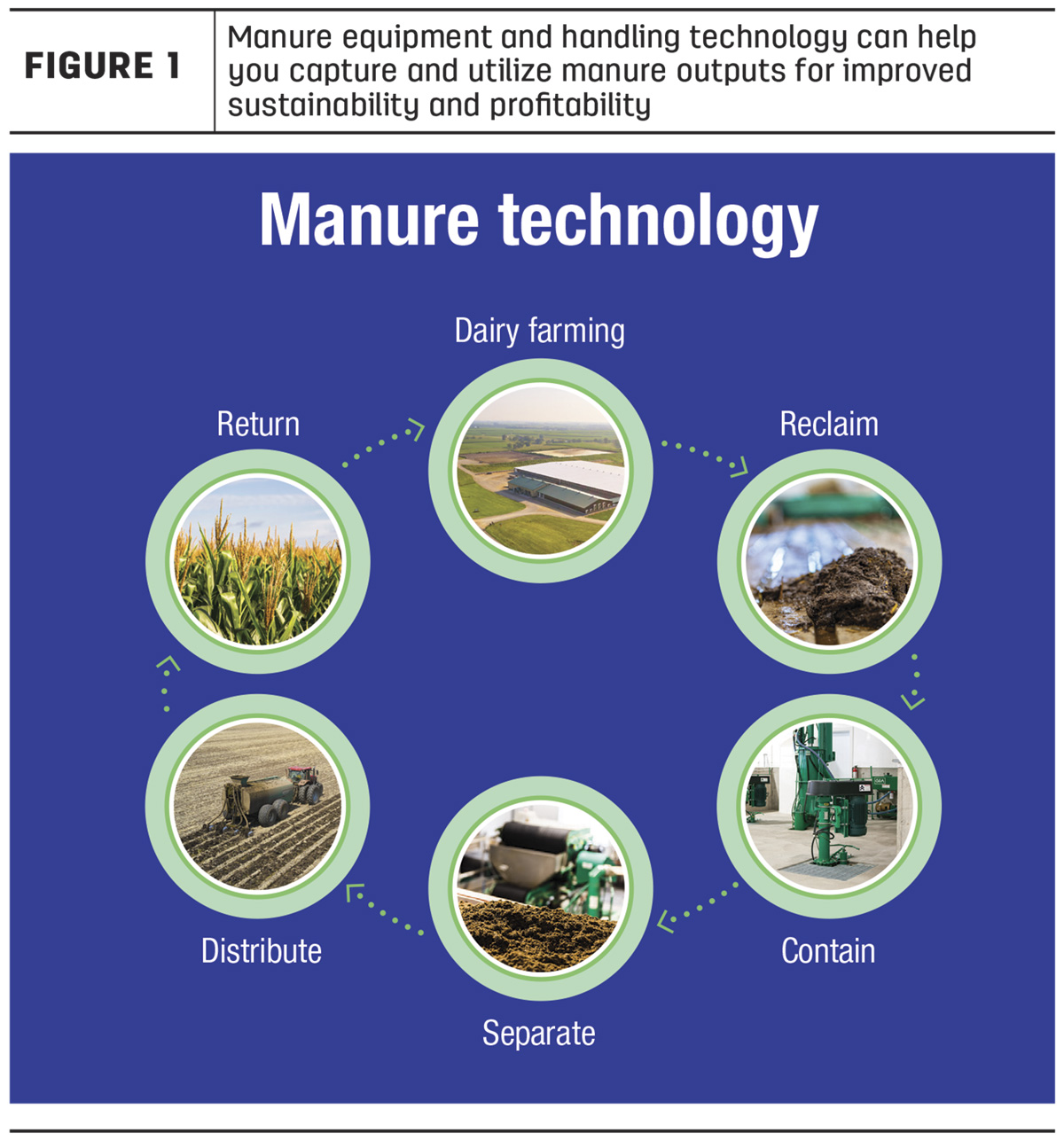

Historically, manure management focused on full-circle farming – crops are grown and harvested, fed to animals for meat and milk production, and the manure is collected and returned to the soil to provide nutrients for the following year's crop production. Today, many farmers are incorporating manure separation as a crucial part of the manure management process.

Manure separation allows you to reclaim some of the wasted product for use back on the farm or as a marketable commodity. This opens potential profitability for your business and has many implications for sustainability, including:

– Fiber removal: Removing fiber from liquid manure reduces overall manure volume by 5% to 15%. This removal increases the storage capacity in existing lagoons and reduces the time spent hauling manure to the field. Separated fiber can be used as a bedding source, replacing sawdust, straw or sand.

– Water conservation: Water is a natural resource that is very difficult to recycle. Water is used on farms for animal consumption, crop growth and manure collection. Some manure-handling equipment allows water reuse for manure collection multiple times and then can be used as a moisture source for growing crops.

– Carbon reduction: The U.S. agriculture industry has committed to a 50% reduction in carbon emissions by 2050. By removing and reusing water from manure, the amount of manure transported to the field is greatly reduced, resulting in less fossil fuel consumption.

Build a strong team

One of the most important things you can do to set yourself up for a successful, sustainable future is to build and develop a strong team of advisers.

There are many options for manure equipment and management. And it is almost impossible for you to know all the options, their pros and cons, and potential return on investment. That is where your team can come in to help you wade through the information.

Start building a network of trusted advisers that can help guide you in understanding the latest manure sustainability options and how they pencil out for your farm. This team may include your manure equipment company representative, local equipment dealer, banker or financial adviser and trusted peers.

Start now

It can be easy to get "decision paralysis" when trying to determine the best direction for the future of your farm’s manure management. Is it a digester? Sand separation? A new technology that has not come to market yet?

It is important to research to find the right opportunity for you and your business. But there is also a chance of waiting too long. Many digester companies have projects scheduled two to three years out, and other manure equipment may have a year or more timeline for installation.

Work with your team to get started and map out a strategy for your dairy that offers both short-term ROI and long-term sustainable growth. A few questions you can ask to get started are:

– What are my sustainability goals?

– What is the potential ROI of my equipment investment?

– How can I capture additional revenue opportunities from manure products?

– What do the support and maintenance look like for this equipment?

Delaying decision-making can add to that timeline, causing you to lose out on profit potential and sustainability benefits you could have captured.

Taking those first steps toward a more sustainable future will help you make continual improvements toward your manure management goals and bridge the gap between where you are and where you want to be.

.jpg?t=1687979285&width=640)