We all recognize the classic picture of a farmer or nutritionist in the feed alley on a farm, grasping a handful of feed and sifting through it with their fingers. During this activity, I always try to compete with myself to identify the different ingredients in a mix.

One ingredient that's easy to spot is cottonseed. From a visual perspective, with the cotton lint and unique shape, whole cottonseed is an intriguing ingredient. The nutritional attributes are similarly interesting. Because of this uniqueness, there are a number of items to keep in mind when utilizing cottonseed in a ration. The steps to ensure success in feeding cottonseed include choosing, finding, buying, receiving and mixing.

1. Choose

Choose if cotton is the right fit for your dairy. The choice to include cotton in a ration relies on several factors. First, we may be forced to feed cottonseed due to low forage inventories. Cottonseed can serve as a good forage replacement because of the combination of effective fiber and protein content. Another reason to choose cottonseed would be to serve as a source of essential nutrients. As mentioned, cottonseed is a good source of fiber and protein. However, it is also an excellent source of fat. Finally, you may choose to feed cotton to support high performance. Because of the unique makeup and concentration of nutrients, cottonseed can be used to support high production.

The other choice you need to make at this stage is how much cotton you want to feed. Although research trials have pushed cottonseed inclusion over 30% of the ration, generally, cottonseed in dairy rations ranges from 1 to 6 pounds per head. The rate at which to choose depends on the factors for which we are putting cottonseed in the ration in the first place.

2. Find

Cottonseed has become a well-used ingredient across the industry. With this, cottonseed has become ubiquitously available, and you can find it in most places you find other commodity ingredients. Following the ginning process (removal of the cotton from the seed), most cottonseed will be purchased by brokers and go into storage. From there, feed mills, secondary brokers and dairies can purchase cotton. Generally, if you have a broker or mill you work with to get other commodities – such as corn gluten feed or soybean meal – they can assist you in finding cottonseed.

3. Buy

The next step is buying the cottonseed. Although it seems straightforward, understanding the “buy” is an extremely important step in the process. This includes understanding the value cottonseed presents versus other substitutes. For example, if alfalfa hay is cheap, you likely need a cheaper price of cottonseed to buy cottonseed over alfalfa hay. You can use tools, such as the SESAME software from Ohio State University and FeedVal v7.0 from the University of Wisconsin – Madison – which are often posted in this publication – to see how the buy of cotton compares to other feed ingredients.

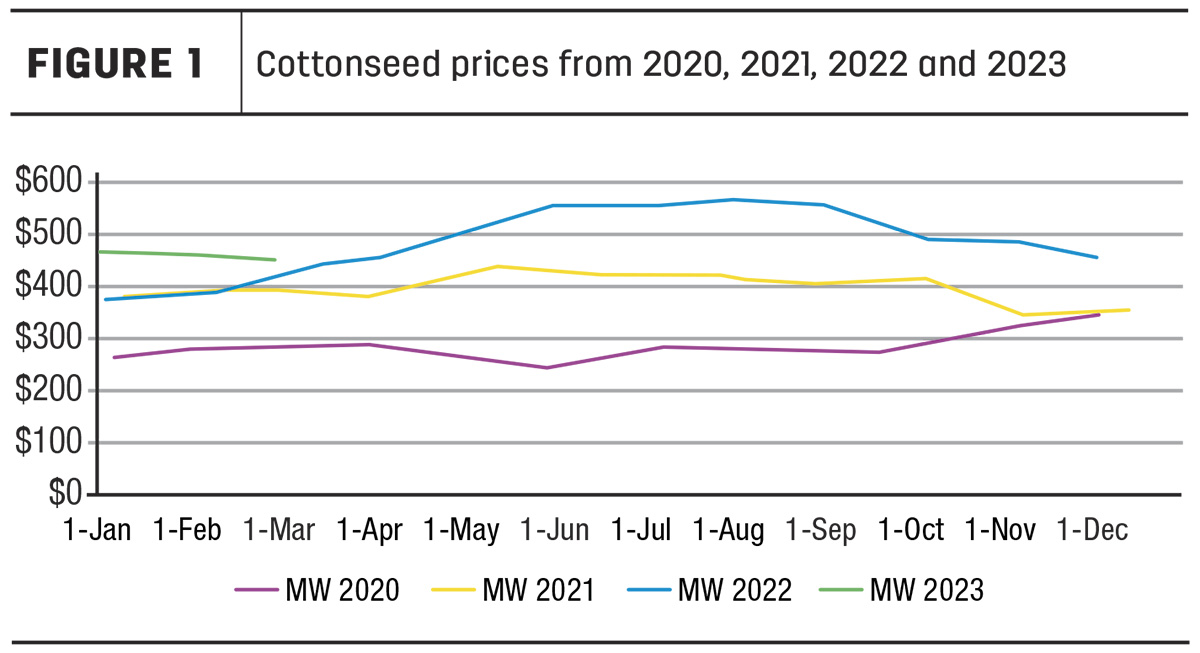

The other half of getting the buy involves determining the right time to purchase or contract the product. With cottonseed, there is often a dip in prices shortly after harvest during the initial "gin run." Basically, during this time, cottonseed may be discounted as gins, and brokers will attempt to sell directly to the market before having to move the cottonseed to storage. Outside of gin-run cotton, many brokers will offer a variety of contracts of various lengths. Although I am not a risk management adviser, my best advice is to understand the previous and current prices of cottonseed to understand where the contract quotes compare with history. Using historical pricing (Figure 1) can help you make the decision on when to pull the trigger on a contract.

4. Receive

Again, although receiving a feed product normally doesn’t require much planning, the unique characteristics of cottonseed require more attention. Cotton is often transported from the South – where the production and gins are located – to the other large dairy markets by rail, semi-trailer or barge. Each of these modes of transportation requires additional transloading. In the cases where cotton is brought directly to the dairy, walking floors or live bottoms would be preferred over a hopper, as cottonseed will not flow like a grain or meal product. If it is desired to bring cotton through a protein mix from a feed mill, most mills will need the inclusion of cotton in a mix to be at or below 300 pounds per ton for the mix to flow through the mill. Be especially cautious putting cotton into the mix if there are other fat products in the mix and if the mix will be stored in a bulk bin. The extra friction created by the cottonseed moving through the auger can cause fat to soften and build up on the auger flighting.

5. Mix

The final step is mixing the cotton into the total mixed ration (TMR). The primary point of advice here pertains to feeder training. Cottonseed is a very difficult ingredient to load, as it binds together and falls out of the bucket in clumps. Be sure to encourage feeders to take time and caution when loading cotton. Adding cottonseed to an on-farm premix or commodity mix is preferred to reduce loading deviations. If the cottonseed is added to a larger protein mix from the mill, much of the loading concerns can be avoided.

Cottonseed is an excellent ingredient in lactating rations. Following the five steps of choosing, finding, buying, receiving and mixing of cottonseed can ensure success when implementing whole cottonseed on your dairy.