Today’s dairy cows produce more milk than ever before, and who knows where the future is heading. Ten years ago, it was unheard of to milk herds of cows averaging over 100 pounds of milk per day and having somatic cell count (SCC) averages under 100,000 – which many dairies are now achieving. Along with this higher production, the milk flow rates in the parlor are far surpassing what we have ever seen before.

The current dairy industry is focused on milking as many cows as possible per hour because this single number is one of the three that impact a dairy’s profitability the most. Goals for herringbone and parallel parlors used to be 3.5 to four turns per hour, but now we see dairies exceed six turns per hour with very high production and excellent quality.

In a double-20 parlor, two extra turns per hour would mean 80 more cows per hour milked in the parlor. The same is true for rotary parlors, especially larger ones (over 100 stalls). Goals used to be 5.5 to 6.5 turns, and now many are exceeding eight turns per hour. The bigger rotaries are now spinning faster in order to justify the bigger size.

Too many dairies think the quicker the units are attached, the more cows can be milked. Unfortunately, this isn’t true – especially if we pay attention to the cow. The most successful dairies put the cow and her health as a priority and are rewarded with better milk production, more milk per stall per day and excellent milk quality when units are attached at the proper time.

Lag time

Lag time is defined as the time from stripping teats to unit attachment. There has been a lot of research done throughout the world, and the data has clearly shown that proper lag time has a huge impact on parlor performance. A common error is to think lag time starts at first touch (pre-dip) to unit attachment.

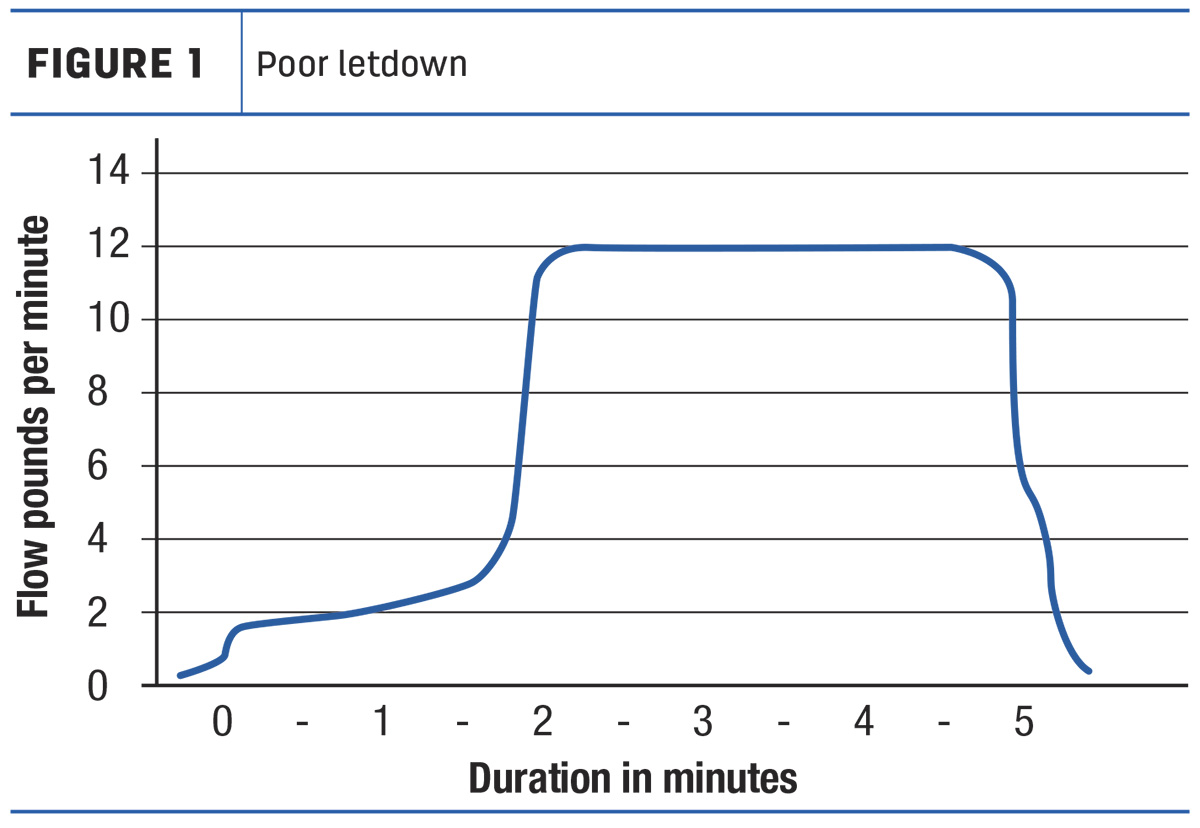

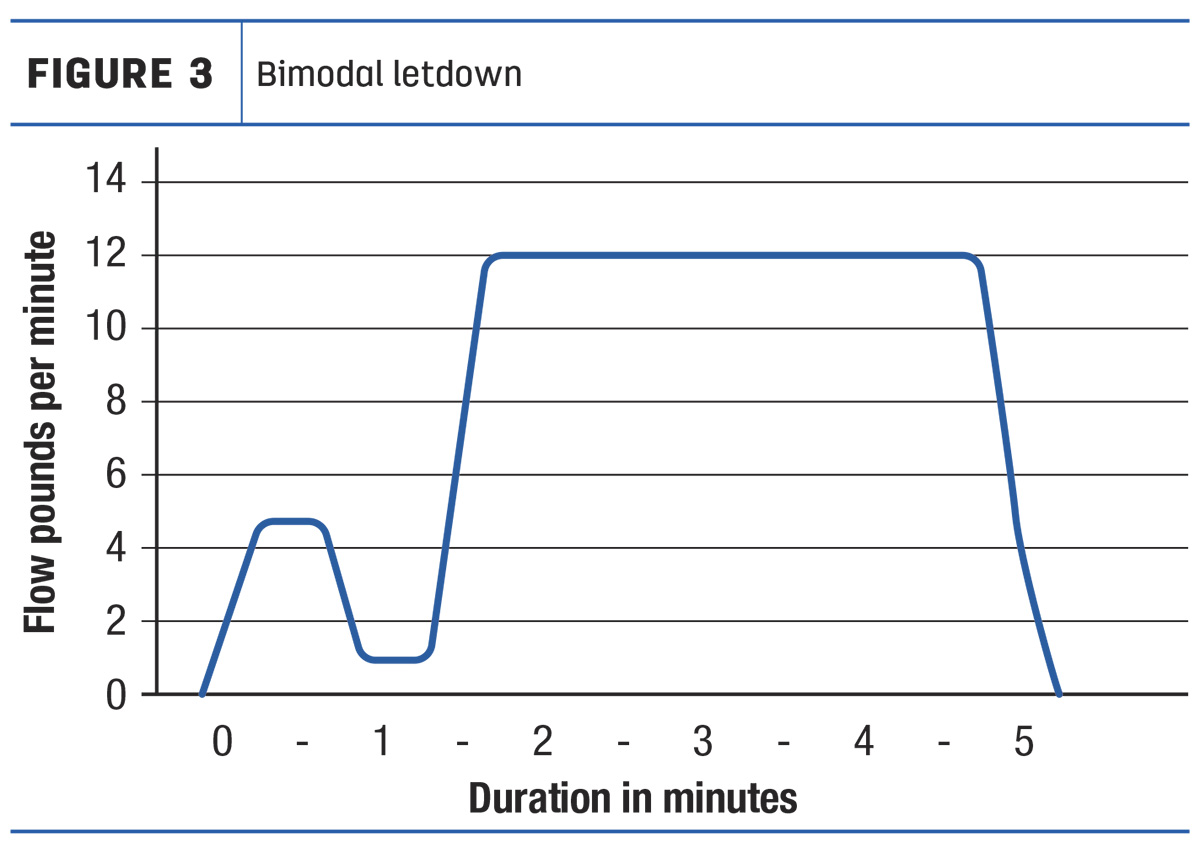

Five to 10 years ago, the recommended lag time was 45 to 60 seconds, but this created slower milkings and caused a higher risk to poor teat end health due to both bimodal letdowns and overmilking. Bimodal letdowns occur when a cow has an initial milk flow, followed by no flow, and then milk flow continues 15 to 45 seconds later. Over-milking occurs when there is a high claw vacuum with no milk flow.

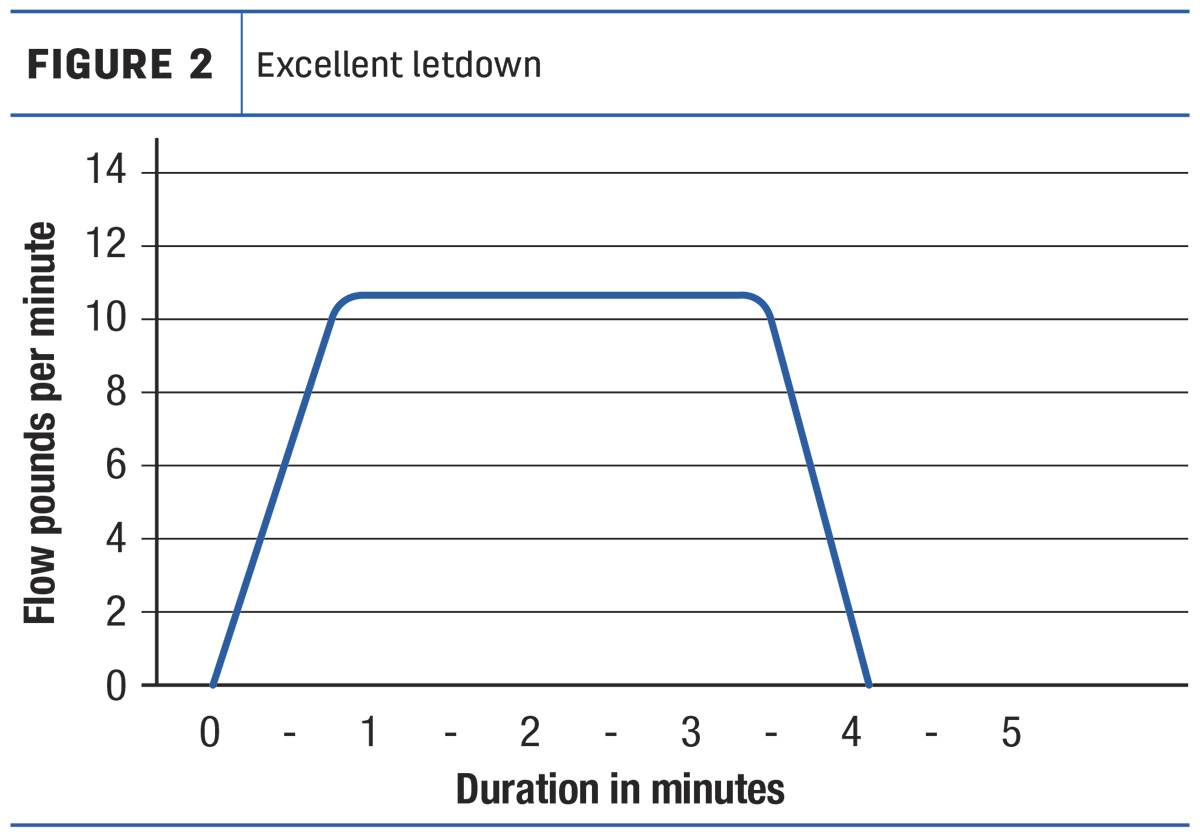

The latest data shows the best lag time needs to be a minimum of 90 seconds, with up to 200 seconds being acceptable. Longer lag times ensure better oxytocin release into the udder so there is not just cisternal letdown but alveolar letdown.

Short lag times are an issue in rotary parlors. Increasing the lag time by moving the people attaching units further away from the entrance results in cows being milked sooner and fewer cows going around the rotary a second time. It is a hard concept to convince a dairy to wait to attach units, but those that do see shorter durations and more milk per stall per hour. A common issue in rotary parlors is when employees edge closer to the entrance of the rotary to attach units sooner, rather than waiting for the cows to come to them. There is a huge advantage if employees wait to attach units, ensuring a proper lag time.

By the numbers

Milking durations have reached new lows, ensuring more cows being milked. I have dairies with full udder prep and over 100 pounds of milk getting durations for the entire herd of 3,500 cows around three-and-a-half minutes. Five years ago, the durations were over five minutes. Our goal now for herds averaging over 100 pounds is four minutes or less duration. Besides duration, there are several other measurements you can monitor to see if your dairy has adequate letdowns or not.

The old goal was to get dairies to average over 7 pounds of milk per minute for the entire herd. Pounds per minute is one of the best measurements of the total milking process. It is affected by udder prep and equipment setup and changes are seen in this number quickly. New goals are now 8.5 pounds per minute or higher. A recent visit found a large dairy that had 9.1 pounds per minute average for the whole herd.

Another great number to follow is pounds of milk per cow in the first two minutes. Five years ago, 15 to 16 pounds of milk in the first two minutes was excellent. Today, dairies are seeing 19 to 22 pounds of milk in the first two minutes. This number is impacted by udder prep and, generally, the higher this number is, the shorter the durations are.

Turns per hour is easy to monitor, but measuring pounds of milk per stall per hour is a much better number to observe. In the past, the goal was 100 pounds per stall per hour, but with better flow rates it is common for dairies to get over 200 pounds per stall per hour. Rotary parlors are seeing even higher numbers due to more turns per hour.

We really don’t know where the future will be, especially if we think about how much change there has been over the past 10 years. High-production dairies now have pens of cows with production averages over 160 pounds per day – which is very exciting. The key is to have a milking system and udder prep that can properly milk these cows and the cows of the future. My goal is to always do what is best for the cow and make a dairy more profitable. The correct lag time is one of those things that can impact both cow health and profitability for every dairy with basically little investment.