Manure has valuable nutrients and needs to be treated as such. Manure needs to be on the forefront of the farm management’s team mind, not the back. That being said, in the best interest of the operation, should manure be handled in-house or should a custom applicator be hired? There are several factors to consider when making this decision.

Size of the job

Consider the amount of manure to move and what equipment the farm has. Does the operation have any equipment? If so, is the appropriate equipment available to do the close fields, but perhaps you need to hire a custom applicator to go the farther distances? Or can all locations be done by the farm? How many gallons does the operation require to be moved? Is it a small operation with a few 100,000 gallons or a large farm with several million gallons?

Availability of custom applicators

Are there custom applicators in the area or does the job have to get done by the farm? If there are custom applicators, what is their availability? I would highly suggest asking them about availability three to six months ahead of time. Preplanning benefits everyone.

Employee availability

Are there employees available during the busy season to get manure out? Those employees who are handling the manure should have an idea of basic agronomy, manure regulations and knowledge of setbacks. Can the operation dedicate an employee or two to handle the manure? Is the operation willing to invest the time and effort to properly train those employees in manure management?

Economics

Manure is a valuable resource that needs to be applied correctly to minimize runoff and maximize nutrient utilization. It should not just be spread on the closest field at the maximum application rate because that is the fastest and easiest. The fastest and easiest does not mean it is the cheapest. These nutrients need to be placed where the soil needs them the most, and that could mean transporting manure longer distances. If the manure needs to be transported farther, and that means an increase in transportation costs, do not let that be a hindrance. Placing the manure where the nutrients are needed makes the most economical sense.

Imagine having a dry sponge and then adding water to it. The sponge can only hold so much water before water starts leaking out. That sponge is the same as soil, and water is the same as nutrients. The soil can only hold so many nutrients before they start leaving and causing issues in places where nutrients should not be. If the nutrients are placed in the closest field and the soil does not need them to grow a crop, it is a waste of nutrients and a waste of time and money. On the other hand, if the nutrients are transported down the road, placed in a field where they are needed to help grow a healthy crop and the cost of transportation is the same or less than the nutrient value of the manure, everybody wins.

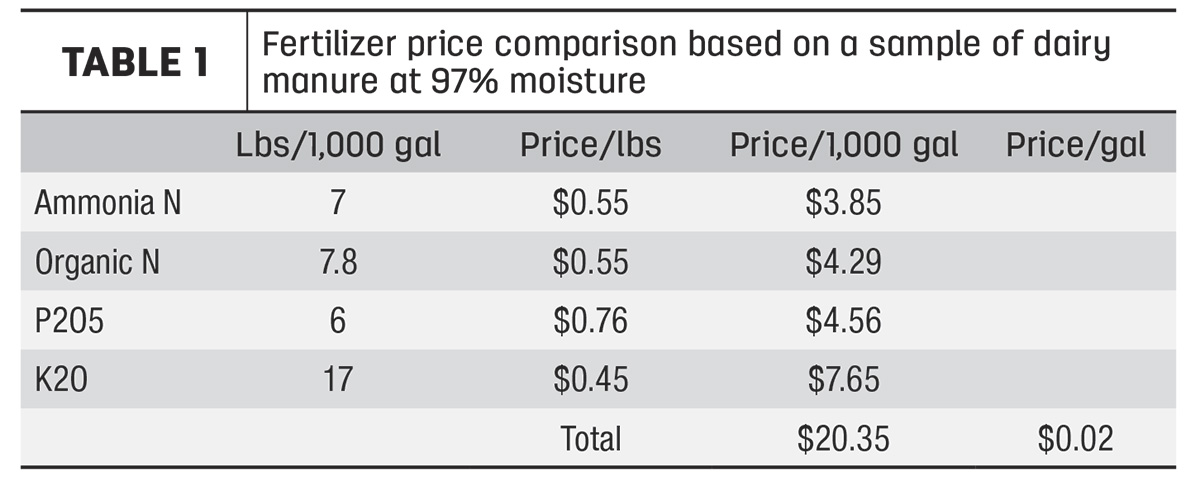

Let’s look at fertilizer prices and compare those to transportation costs in Table 1 with the assumption dairy manure is 97% moisture.

Note these fertilizer prices are based on central Ohio in April 2023. We are also only looking at nitrogen, phosphorus and potassium values. The value does not include micronutrients or organic matter. Manure is a fantastic fertilizer choice and needs to be treated as a resource, not a waste. At the bare minimum, this manure is worth 2 cents per gallon. Manure can be moved a decent amount of distance for 2 cents a gallon.

Manure application system

What types of equipment does the operation require to handle all of the manure? Such equipment might be a dragline, honeywagon and/or dry spreader. Can the farm make the investment to have the pieces of equipment to handle manure? What are the distances to the fields? Is everything within 2 miles, or are there several farther away than that? Distances to the fields and sizes of fields will play a large part in deciding the way an operation chooses to apply manure.

When deciding the manure application system, consider each piece of equipment that is needed for each system. The prices for each set-up can vary greatly. There are many resources to find used equipment.

The following equipment is needed for various manure application systems:

• Tractor, honeywagon and injection bar set-up: tractor, honeywagon, injection bar, pump, hoses, second tractor for lagoon pump, lagoon pump, load tube and hoses

• Dragline set-up: tractor, application bar, hose, lead pump, booster pump, hose humper, tractor for hose humper/hose cart and air compressor

• Dry spreader set-up: tractor, spreader and loader (the more cubic foot capacity the better)

• Other equipment that might be needed: semi truck, tanker trailer, dump trailer and frac tank

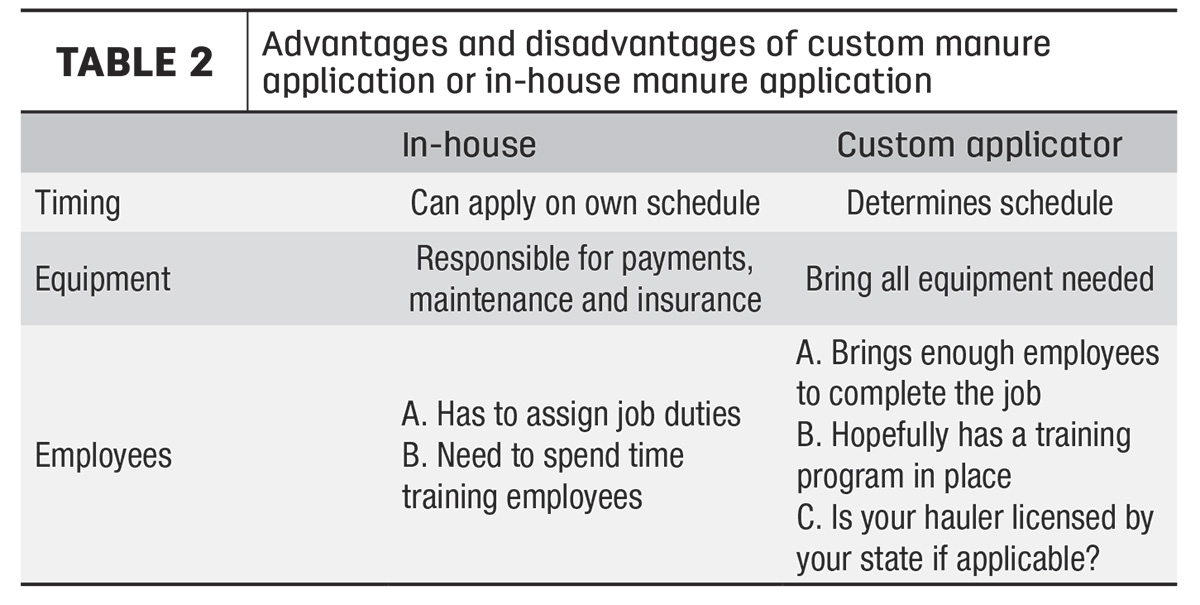

Manure management is not one size fits all. Maybe you can do it all yourself, maybe you need to hire it all out, maybe your operation uses both options. There is not a right or wrong answer, but as a businessperson, you need to know your costs of operation and make decisions based on that. Table 2 provides advantages and disadvantages of each option.

With the increased pressure on the livestock community and the perception that we treat manure as a waste, we need to move the manure down the road and put it where it is needed the most.

With the increased pressure on the livestock community and the perception that we treat manure as a waste, we need to move the manure down the road and put it where it is needed the most.

Author's note: What is traditionally done in Ohio and what is allowed according to the rules and regulations varies greatly depending on the size and location within Ohio, let alone how that compares to other states.

.jpg?t=1687979285&width=640)