“I won’t know my cows as well if I’m not milking them every day.”

This is a common misconception with milking robots. However, the opposite is true. Being a better cow manager is not about spending time – it is about how you use your time.

Robots provide critical data insights to help you be a better herd manager. They deliver a consistent milking experience for the cow, offer more schedule flexibility and help you focus on being a cow person again.

The key to being the best manager is making the most of your time and the robot’s time. Here is how to be an effective herd manager with robots.

Focus on the little things

Whether you are three months into using robots or three years, the most successful robotic herd managers are the ones who focus on optimizing milking visit distribution. Are cows coming to the box well on their own? Can you make adjustments to level the load on the system throughout the day? For example, the cows want to visit the box at 5 a.m. because there is no feed left, and you put fresh feed out at 6 a.m. Putting feed out earlier can help distribute milkings more evenly.

Look at your hours throughout the day and focus on the little things to use every minute effectively. What are your milkings each hour? What are your visits during specific times? Look for discrepancies and how they impact your chores beyond putting feed out – when you run the feed pusher, scrape pens or clean out waterers. Maybe you find cows are not using the robot much around 2 a.m. What if you turn on a radio to help stir up traffic?

Also review problem attachers. These cows take more box time than they should, taking time away from other cows. Maybe you change their milking frequency or limit their milking time to get them out of the box faster.

Little adjustments like this can help you increase efficiency and get more from your cows and the robot.

Seek an outside perspective

Getting an outside perspective can also kick your management up a notch. One significant benefit of strong dealer partners is the view they bring from seeing many farms. They learn from what other farms are doing and can share different approaches.

During one farm visit, I noticed the employee cleaning the freestall barn locked the cows out of the robot to scrape, then ran a milking system wash, tying up the robot even longer. By adjusting the timing of the wash to run while the employee was scraping, the farm gained an extra 10 milkings per day.

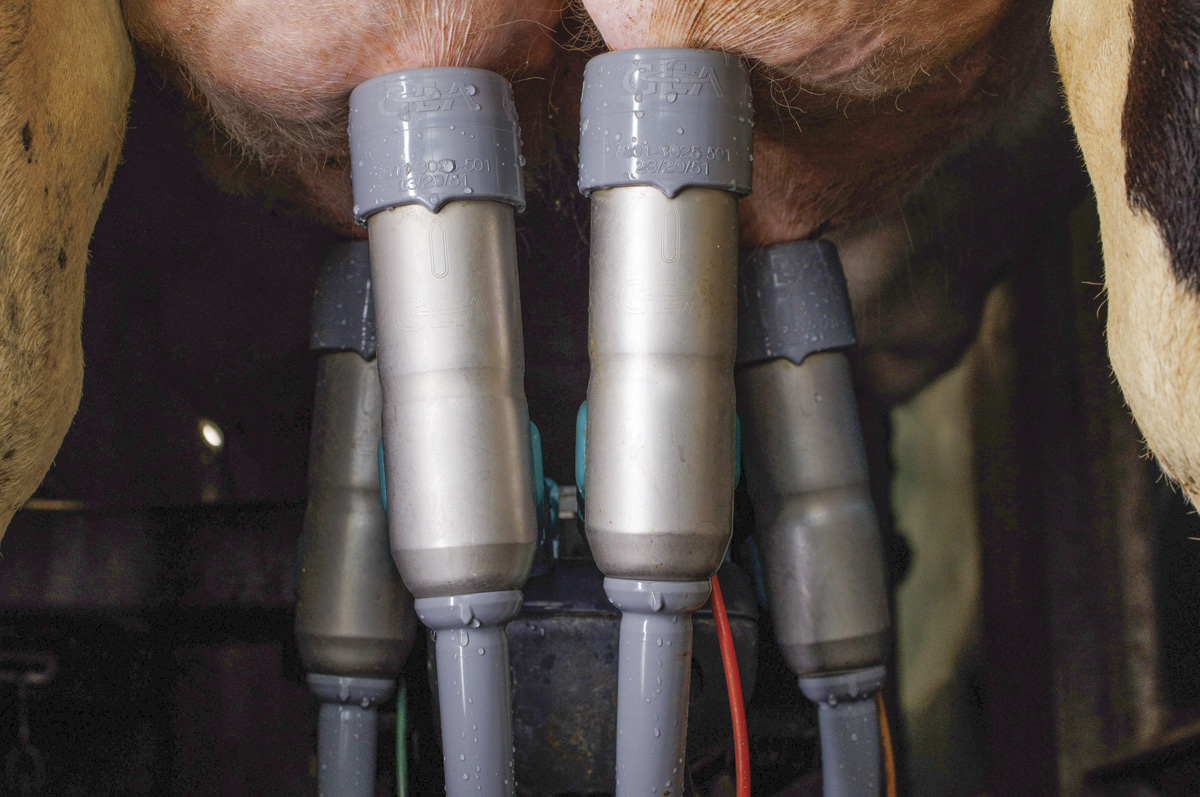

Farms that excel with robots focus on cow maintenance to ensure quick, efficient attachment – routinely trimming tails and singeing udder hair. Just like in conventional milking, cow physiology does not change. We still want 45 to 90 seconds between the first touch and milking. Anything you can do to give that cow a better experience in the robot helps ensure a quick attachment and milkout.

Your dealer partner can share insights like these to help you learn and adjust your own protocols and improve efficiency.

Anything you can do to give the cow a better experience in the robot helps ensure a quick attachment and milkout. It can be as simple as trimming tails and singeing udder hair. Photo courtesy of GEA.

Be open to change

It is interesting to see herd management evolve with years of experience. The best herd managers prioritize reviewing their long-term reports quarterly or annually with their milking equipment dealer or their dealer and robot manufacturer’s herd management expert. During these meetings, review reports for both equipment and cow performance.

Key equipment data to review include attachment time, box time, milk flow, milk per milking and average visits. For herd data, review fresh cow performance trends, average milking intervals based on production and milk persistency. Reviewing your current performance and comparing it to three, six and 12 months ago can help identify where you should spend more or less time and adjust what you are doing.

For example, if you spend a lot of time training fresh cows, how can you reduce that time? Can you make a fresh cow pen? Or implement a fetch pen, training lane or training robot? Could you decrease the number of cows in your fresh cow pen?

Are there tasks you can automate? Consider dry-off: By changing feed, groups and milk permissions, you can help those cows gradually step back their production before dry-off to make it an easier transition. And you reduce the need to retreat or reseal cows, especially because cows typically milk more in late lactation with robots.

A slight creep or change is not always noticeable on a daily basis – whether that is an extra second of attach time or an extra second of box time, but it adds up over six months or a year. Staying on top of maintenance, keeping track of problematic cows and working with your trusted advisers regularly will keep your system performing at its best.

Remember, you are still a cow person

Do not let the robot get in the way of using your cow insights to make decisions. Typically, 90% of the time when I’m working with farms, their challenges are not robot-related.

For example, a farm was getting “no feed” alarms. They could not figure out why the cows stood next to the boxes and would not go in them. It turned out, the feed was going into the bin but was not dispensing into the feed bowl due to water getting into the feed auger and plugging the feed tubes.

On another farm, cows stood on two different levels while waiting for the robot. We updated the area to be level by adding less than 2 square feet of concrete for the cows’ rear feet to stand on. The cows were more comfortable waiting for the robot, which also helped with cow traffic.

Another farmer, after three years in a robotic milking system, was looking to keep his cows cooler in the hot summer months. He installed a sprinkler on the exit lane, just outside the robot. The cows were more enticed to move around the barn, water was not wasted on the feed lane and it kept the robot area cleaner.

Happy cows make for a happy farmer. Making the most of everyone’s time, maintaining your robot and a consistent cow environment will result in good letdowns and milkouts.

Take the leap to robotic milking with a strong herd management and equipment partner at your side.