Footbaths have been used for over 25 years for the control of infectious hoof diseases. In drawing on years of consulting with farms all over the globe, there are do's and don’ts to consider when designing a footbath and implementing practical protocols, including:

- Effective design

- A solution for controlling and aiding the recovery of lesions

- Is footbath automation the new frontier?

- Costs and cautions

Effective design

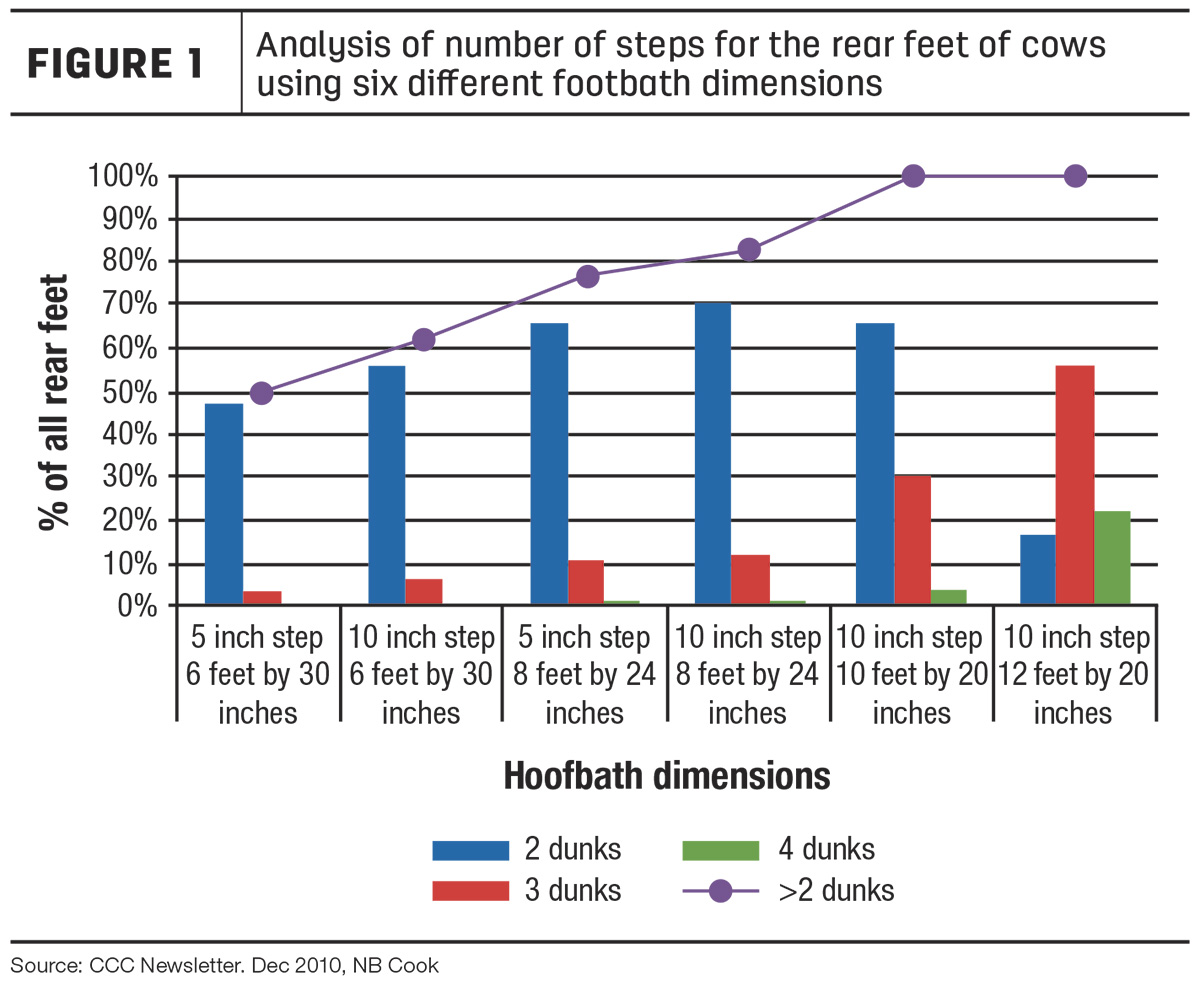

Several aspects must be considered for an effective footbath. The effectiveness of the solution can be measured by anecdotal evidence, especially solution contact time. Six seconds of contact time, or three immersions with each rear leg, with each pass through the footbath is optimal (Figure 1). A 2010 study showed that a longer footbath (12 feet) with a 10-inch entrance and exit step resulted in a higher percentage of rear leg immersions. This goes along with results in-field where the 10- to 12-foot footbaths produce the best results.

We believe a single cow pass footbath with 20- to 24-inch width and high solid sidewalls has improved cow flow as well as less manure contamination compared to wider baths (Photo 1). A footbath must be designed with minimal slope and water use. A long, narrow bath yields the best results while using less water and chemicals. On large farms, two narrow baths side by side will be cheaper to operate than one wide bath. When the footbath is not in use, the cows should have the option to bypass. This saves on labor and water expenses.

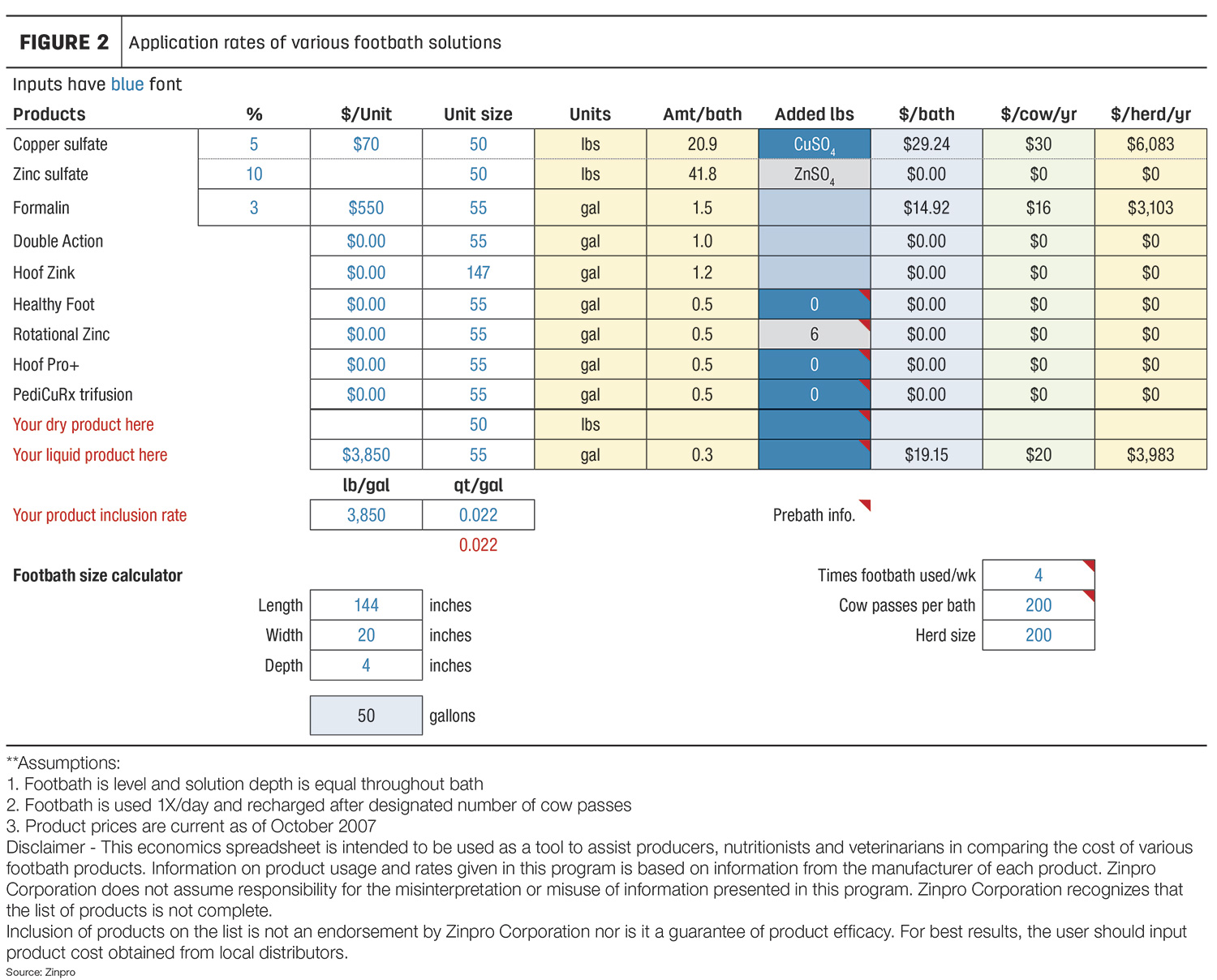

Let’s assume a footbath 20 inches wide, 12 feet long with 4 inches of solution requires 50 gallons of water. The solution should be renewed every 200 cow passes. This is because over time manure contamination reduces the effectiveness of the disinfectant. It is proven that 6-feet-high sidewalls starting 6 feet before the bath to 6 feet past the footbath improves cow flow and reduces defecation into the footbath. The best way to get more cow passes from the solution is a narrow race. The more cows that can pass through the same 50 gallons of effective solution, the cheaper the cost of running the footbath. Often, it is not taken into consideration that more water, chemicals and frequent bath changes increase the cost of running the footbath. If we can double the cow passes per 50 gallons of solution, we reduce the cost of running a bath by 50%. This can be accomplished with long, narrow footbaths with high, solid sidewalls.

A solution for controlling infectious hoof lesions and aiding the recovery of claw horn lesions

It is well known that leg hygiene score plays a huge role in efficacy of any footbath solution. Another aspect that is often overlooked is the need for a regular weekly schedule. The number of times a footbath is used must be determined by leg hygiene score and infectious lesion occurrence. The higher the score, the more days it should be used. Conversely, the lower the leg hygiene score and infectious lesion occurrence, the fewer days the footbath will be in use.

When hooves and legs are soiled, no disinfectants can successfully reach the skin barrier. In such cases, we can use sodium hypochlorite or detergent with salt for two to three days per week to clean the hooves and legs. Disinfectants can be used for the remaining days. A successful footbath routine will control digital dermatitis (DD) and aid in the prevention of foot rot. It also assists in the recovery of other hoof lesions.

Footbath automation: The new frontier?

In the last few years, completely automated footbath systems have been developed and installed on many farms. Automated systems also remove employees from handling hazardous chemicals. Today’s systems function well with products available in liquid form and have added consistency to dispensing. The automated systems are generally very reliable and do not miss a day. Although it is fully automated, it still requires monitoring. Monitoring includes checking that the timing of the filling and refilling is done at the right time. The second and most important thing is a weekly check that the right amount of disinfectant is added to the solution. Over time, the amount of disinfectant dispensed will increase because of the way the dispensers work. If the systems are not monitored, overdosing often results in additional hoof health problems.

Several of the footbath solutions for automated systems today are organic acid-based. With regular pH of the skin being at 3.6, it is very important that the starting pH of a solution does not go lower than 3.0. In cases where there is a problem with dispensing the correct amount of solution and the pH goes well below 3.0, the typical sign is more DD lesions with hyperkeratosis (Photo 2). This results in more chronic lesions. The same would be true when using formalin at greater than 3%. In both cases, data has shown an increase in non-healing claw horn lesions and more foot rot.

The typical sign of an incorrect footbath solution concentration is more DD lesions with hyperkeratosis. Photo provided by Karl Burgi.

Costs and cautions

In the last several years, the cost of raw products used in footbath solutions has increased. To reduce the cost of footbathing, it is important that everything is assessed and best practices are used with the intent to increase cow passes through a footbath. The University of Wisconsin School of Veterinary Medicine offers a test that measures solution efficacy. This is an excellent test to complete when something is not working as it should.

Farms using copper sulfate can increase solubility by adding a small amount of the right acidifier. This will reduce copper use by 50% to 66%. Copper sulfate disposal is concerning because in some areas there are high copper levels in the soil, which can affect plant growth.

Formaldehyde is a suspected carcinogen and extra caution (eye protection, respirator) must be taken when handling it. It works incredibly well with fully automated systems. It is not effective in temperatures below 45°F. When diluted, formalin will become inactive and not create an environmental disposal hazard. Products formulated with organic acids can be very corrosive to equipment and concrete. There are things that can be done to protect structures and floors, but the most important thing is to make sure the correct rates are used (Figure 2).

Good hoof health monitoring is essential in making sure footbaths are effective. Trim records show the results of a footbath solution change or the efficacy of the solution. With good records, we can adjust frequency of footbath use and reduce the overall cost of running a footbath. It is crucial that the system in use is consistent and simple to implement.

Of course, it would be beneficial to have more science-based results, but anecdotally following proper product protocols on a regular basis has shown to be highly successful. More dunks into the solution for each hoof is achieved by a longer 10- to 12-foot footbath with a 10-inch entrance and exit curb. Solid sidewalls up to 6 feet tall have been shown to decrease manure contamination of the solution and increase cow passes. Use a footbath efficacy test for fine tuning. Data shows that lowering the overall leg hygiene score will reduce infectious lesion occurrence, which then also reduces the frequency of footbath use as well as overall cost. Most importantly, we must construct a system that is safe for people, cows and the environment.