Cover and flare systems are suitable for dairy farms of all herd sizes and can help mitigate methane and other emissions while improving climate resiliency. Impermeable covers are gas-tight plastic membranes installed over the surface of a suitable manure storage structure to capture emissions and exclude rainwater (Figure 1). Biogas collected from under the cover can be combusted in a flare to reduce the potent greenhouse gas, methane, and to lessen potent carbon dioxide. Rainwater can be temporarily stored on the cover and used on-farm or pumped into an appropriate vegetated area.

COMPONENTS OF A MANURE STORAGE IMPERMEABLE COVER AND FLARE

Engineering and site work

Manure storages (earthen or tank) must be engineered and constructed to support cover loads and other external loads (snow, vacuum, wind). For earthen manure storages, covers, or liners if the cover is welded to the liner, are typically secured by a one ft2 concrete anchor below grade around the perimeter of the storage. For manure storage tanks that can be covered, the engineer must devise a system to anchor the liner to the tank. Fencing is an important safety and security measure and can prevent unwanted wildlife from getting onto and potentially damaging the cover. Electricity is also needed at the site to power pumps, ignite the flare, control systems, and wireless communication equipment (if installed).

Cover materials

Covers are typically constructed of 60 mil HDPE geomembrane, though 40 mil and 80 mil thicknesses are also used. The material is manufactured according to National Standard Material Specifications (#594) and typically have a 20- to 30-year lifespan. Installation may only be guaranteed for 12 to 24 months and a 10-year rollback for solids removal is recommended.

Weights, pumps, and water lines

Weights, typically made from tubes of geomembrane filled with concrete and welded to the cover, are used to prevent billowing and associated wind forces on the cover, and to channel rainwater to pumps for removal (Figure 1).

Simple submersible pumps with a timer-off switch are used to remove water from the covers. Water can be pumped to a pond for use or to an appropriate vegetated area where the water can infiltrate into soils. Direct discharge to a natural waterway should be avoided.

Manure system

Solid-liquid separation (and sand-separation as relevant) is a prerequisite to cover a manure storage or solids accumulation will substantially reduce storage volume and create storage emptying problems. The screw-presses often used by Northeastern dairy farms remove about 10 percent of the mass and 50 percent of the total solids.

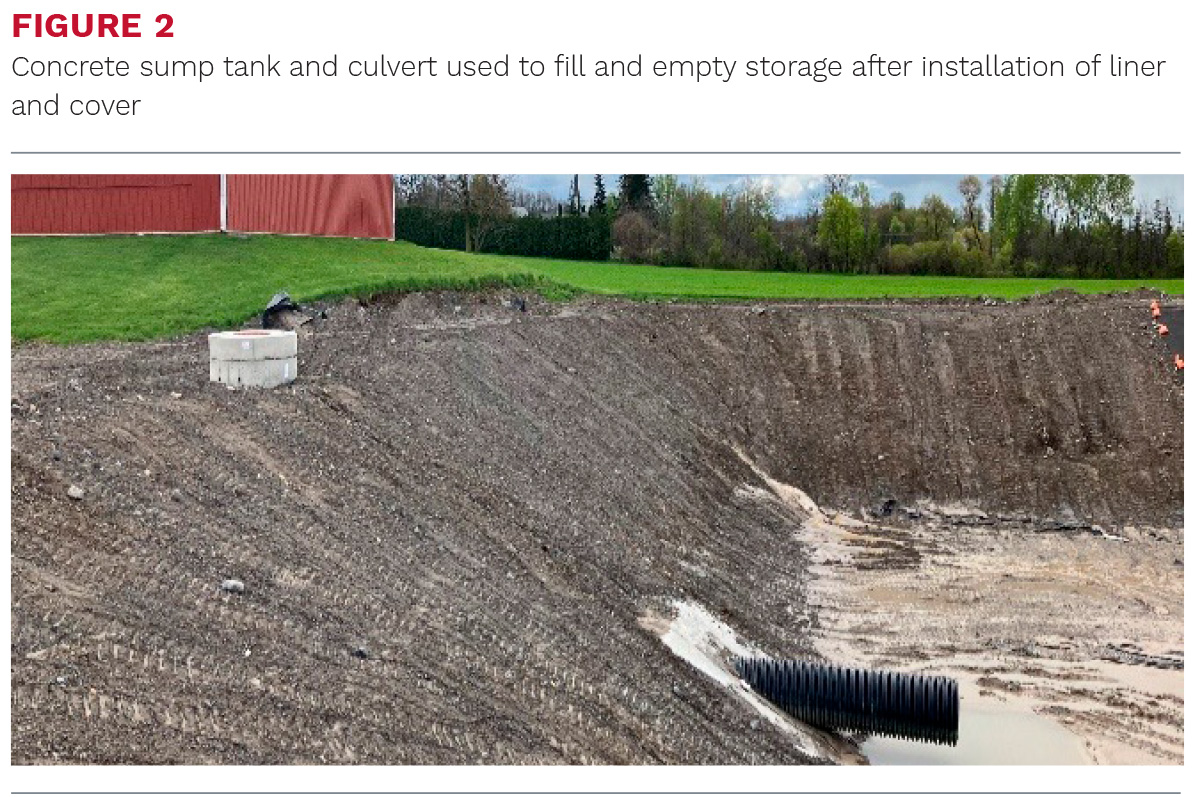

A means of adding and removing manure from the gas-tight storage is also needed. The current practice is to construct a sump tank with manhole connected below grade via a culvert (typically 30 inches) to the bottom of the manure storage (Figure 2).

Optional are sludge lines to facilitate manure recirculation and removal of settled solids during manure storage emptying.

Biogas collection and combustion

Biogas is collected under the perimeter of the cover with perforated drainage tile. Gas can be collected passively or mechanically with the aid of a blower. A buried biogas line with condensation trap is used to transport biogas from the storage to the flare skid that includes a flame arrestor and monitoring equipment. Pressure relief systems are also critical to prevent over-pressure of the cover. Early designs utilized passive vents, but new systems often have a manually controlled valve to vent excess biogas.

BENEFITS OF A COVER AND FLARE SYSTEM

Cover and flare systems can bolster a farm’s climate resiliency and mitigate methane from manure long-term storage.

Covering a manure storage with an impermeable membrane diverts rainwater, preserves freeboard, and reduces the total volume of manure the farm must handle. For example, in central New York where annual rainfall is around 40 inches, this amounts to over 1.08 million gallons for a one-acre storage. Assuming half of the rainwater evaporates and manure-handling costs are $0.01 per gallon, this equates to around $5,400 in hauling cost savings. Further, covers offer resiliency to extreme rainfall events which are expected to increase as the global climate warms.

Capturing and flaring biogas from covered manure storages reduces odor and mitigates methane by converting it to carbon dioxide, which has nearly 30 times less global warming potential. This ability to mitigate a potent greenhouse gas makes impermeable cover and flare systems monetarily valuable in carbon credit markets. This is true for farms with or without a manure anaerobic digestion system. Covering the anaerobic digester effluent long-term storage can further reduce methane emitted from undigested solids, improving the carbon intensity score of the digester energy produced. If a farm does not previously have solid-liquid separation, this practice too may be eligible for carbon credits as less organic solids in storage is less carbon that can be converted to methane.

Manure is a valuable fertilizer that must be land-applied in a manner that ensures nutrients are recycled to the land in an agronomic way. In many regions, manure applied to meet phosphorus demands supplies insufficient nitrogen, and additional nitrogen fertilizer must be imported. The physical covering of a manure storage reduces ammonia emissions, thereby increasing the plant-available nitrogen-to-phosphorus ratio in the manure.

DRAWBACKS

While these systems have farm benefits, they do have a substantial cost. Based on initial evaluation of recent systems installed on dairy farms in New York, expected total costs may range between $6 to $10 per square foot or $300 to $900 per lactating cow. Costs can vary considerably depending on the size of the project, changes to the manure systems, like the need to add solid-liquid separation, and other case-specific parameters. These systems also require daily visual inspections and some additional maintenance to prevent biogas leaks and maintain flare performance.

FUNDING OPPORTUNITIES

Natural Resources Conservation Service (NRCS) EQIP funding includes support of waste treatment, waste separation, and roofs and covers. In New York, the Department of Agriculture and Markets has additional support through its Climate Resilient Farming program. Both of these sources of funding are enhanced by funds from the U.S. Inflation Reduction Act. Contact your local NRCS or Soil and Water Conservation Districts to learn more.

|

This article appeared in PRO-DAIRY's The Manager in November 2023. To learn more about Cornell CALS PRO-DAIRY, visit PRO-DAIRY. |