When planning a hose system or pipeline, we must know what the capabilities of our pump are and what the losses in our system will be. In a previous article "Understanding pump performance curves" we learned how to determine the capabilities of a pump. The pump provides energy as Total Dynamic Head (TDH) that supplies the system. Remember, TDH is measured in feet and can be converted to pressure as PSI by dividing by 2.31.

Friction loss is the consumption of energy. By definition, "Friction loss is the loss of energy or 'head' that occurs in pipe flow due to viscous effects generated by the surface of the pipe."

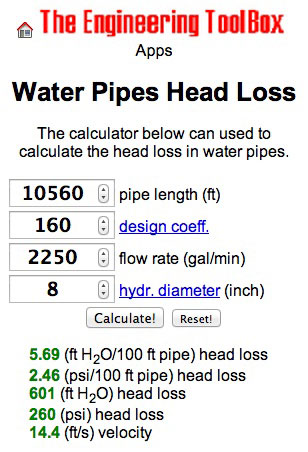

We need to know four things to calculate friction loss using the Hazen-Williams Equation ( Figure 1 ):

1. Pipe length (feet)

2. Design coefficient (type of pipe rough/smooth)

3. Flow rate (gallon per minute)

4. Inside diameter (inch)

The Hazen-Williams Equation is based on empirical data and gives us reliable outputs:

1. Head loss: Feet

2. Head loss: psi

3. Velocity: Feet per second

For an example, let's plan a hose system to service your fields within two miles of the lagoon.

You bed with sand, so we will be sure to keep the liquid velocity above 13 feet per second to ensure the sand stays in suspension and doesn't settle out or fill the hose.

(Length of pipe: 2 miles x 5,280 feet = 10,560 feet)

Lay-flat hose is super smooth, and will swell under pressure, often giving us better results than C-160 pipe. (Design coefficient: 160)

We want to operate our hose at 200 psi working pressure.

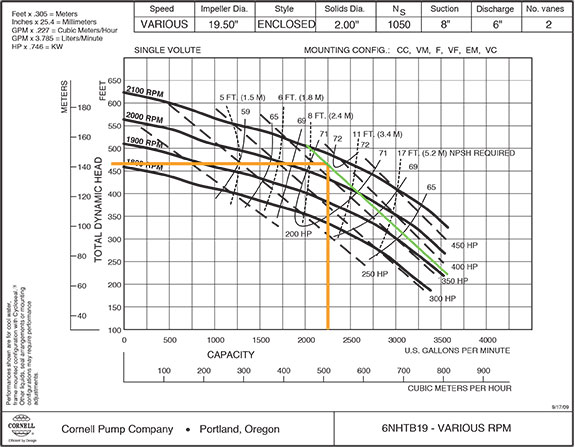

This calculates to 462 feet of head. If we look at our pump performance curve for the Cornell 6NHTB-19 with a 375-horsepower engine, we see 462 feet of TDH will happen at 2,250 gallons per minute. ( Figure 2 )

The energy efficiency of the pump is very good there or at higher flow rates. (Flow Rate: 2,250 gallons per minute)

Naturally, a larger diameter pipe will be less restrictive. Choosing from 6-inch, 7-inch or 8-inch mainline hose, we select 8-inch. (Diameter: 8 inches)

Hazen-Williams Equation outputs for this scenario:

1. Head Loss: 601 feet

2. Head Loss: 260 psi

3. Velocity: 14 feet per second

Then we will add two 660-foot lengths of six-inch drag hose:

1. Head Loss: 304 feet

2. Head Loss: 132 psi

3. Velocity: 26 feet per second

Total System Requirements: 601 feet + 304 feet = 905 feet (392 psi)

Energy supplied per pump: 465 feet (200 psi)

905 feet ÷ 462 feet = 1.9 Pumps

Therefore, two 6NHTB-19 Cornell Pumps are required to fill the requirements of this situation.

Elevation gain or loss can be directly added or subtracted as feet of loss (uphill – subtract) or gain (downhill – add).

If we compare the same situation with using a 6-inch mainline hose, we see a total of 2,739 feet of head loss at 2,250 gallons per minute, requiring six pumps to overcome the total friction loss.

Limiting factors of a system can be the working pressure of the hose or pipe and the velocity of the liquid it can handle. Understanding pumps and friction loss can better inform the investments we make. PD

To learn more about pump placement, contact Nancy Puck using the link below or participate in a PCE Pump School.

Nancy Puck

Puck Custom Enterprises, Inc.

(712) 653-3045