Alfalfa haylage has become a staple in the diets of high-producing dairy cows across the nation, due primarily to its significant contributions of crude protein and physically effective fiber (peNDF) in most TMRs, but still it remains one of the most difficult and challenging forages to ensile properly.

Proper fermentation is predicated upon a controlled, anaerobic process whereby water-soluble carbohydrates (primarily glucose, fructose and sucrose) are converted to lactic acid by lactic acid bacteria (LAB), leading to a dramatic decline in pH and resulting in long-term forage preservation.

Numerous factors affect silage quality, including moisture (dry matter content), forage buffering capacity, ash content, temperature, total protein and volume of air per volume of forage. Alfalfa is especially challenging to ensile due to its buffering capacity and less-than-ideal quantity of water-soluble carbohydrates.

Several of the aforementioned factors represent critical control points where significant management intervention can enhance fermentation and preservation, therefore, potentially avoiding the clostridic time bomb.

What is the clostridic time bomb?

The primary-culprit organism is a rod-shaped, gram-positive bacterium that grows under anaerobic conditions and produces butyric acid, acetic acid and hydrogen gas – Clostridium tyrobutyricum.

Not only significant in the spoilage of alfalfa haylage, this organism is responsible for the late-blowing defect in cheese that can cause considerable challenges in cheese-making and storage.

Butyric acid is the primary indicator that alfalfa haylage has gone “butyric” or “clostridic” leading to a reduction in sugar, elevation in pH, degradation of protein (proteolysis), increase in dry matter (DM) loss, “off” odors and poor feedout performance with potential health effects when fed to high-producing dairy cows.

We recently viewed and analyzed several alfalfa haylage bunkers and piles in Wisconsin that yielded some interesting points for discussion. Specifically, what environmental factors negatively impact alfalfa haylage or what management interventions can significantly improve alfalfa haylage fermentation and preservation at critical control points throughout the process?

Moisture

Clostridic layering or spoilage in alfalfa haylage can be linked to excessive moisture content. This moisture could be inherent to the crop at harvest due to improper wilting time, deep windrows or environmental re-wetting conditions at harvest, such as rain or heavy dew.

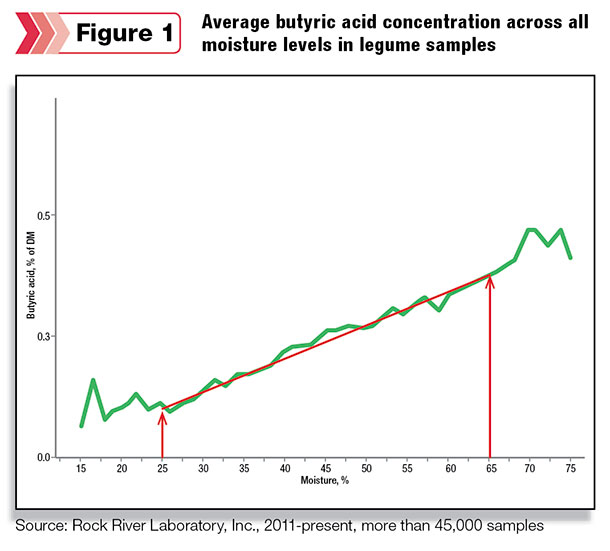

To visually assess moisture in relation to butyric acid, we evaluated data compiled from legume samples submitted to Rock River Laboratory Inc. since 2011 and generated the following figures. Figure 1 shows the relationship between legume moisture and butyric acid.

Notice the fairly linear increase in concentration of butyric acid as moisture increases from 25 percent to 65 percent across more than 45,000 samples. Wetter haylage is more prone to clostridic spoilage and higher levels of butyric acid.

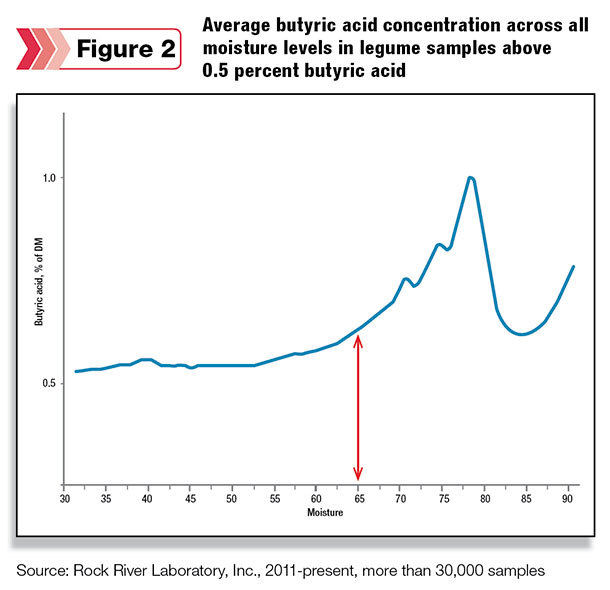

To take this one step further, we sorted only those legume samples with butyric acid levels above 0.5 percent on a DM basis, and those data are shown in Figure 2.

Across a broad range of moisture levels (approximately 30 to 60 percent), butyric acid concentration averages approximately 0.5 to 0.55 percent for all samples classified butyric (more than 0.5 percent butyric acid); however, when moisture exceeded 65 percent (35 percent DM), butyric acid concentration increased significantly. Therefore, in order to avoid a “clostridic time bomb” event, ideally keep alfalfa moisture below 65 percent (DM above 35 percent).

Water-soluble carbohydrates

Water-soluble carbohydrates (sugars) are important for good fermentation. Alfalfa is lower in water-soluble carbohydrates than corn, making it more difficult to ferment.

The carbohydrate content of grasses increases from 6 a.m. to 6 p.m., whereas the carbohydrate content of legumes, specifically alfalfa, increases from 6 a.m. to noon. Particular attention should be paid to time of day and environmental conditions at cutting in order to ensure the highest water-soluble carbohydrate content possible.

Ash

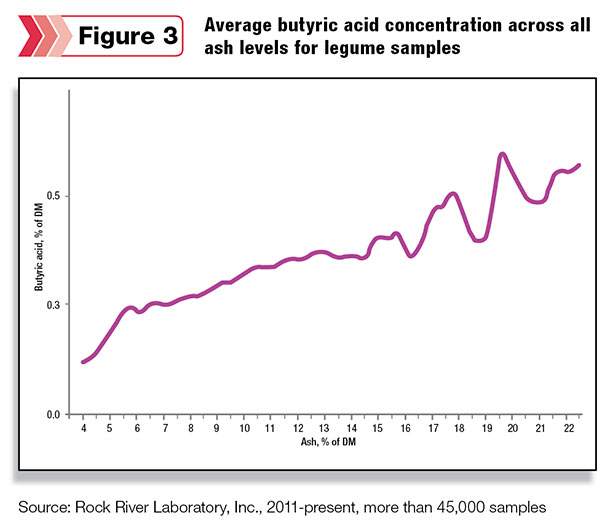

Higher-than-normal ash levels in alfalfa haylage can be a result of picking up additional ash from the soil during harvest and wilting, or substantial DM (sugar) losses due to a secondary fermentation event. Note, with the inclusion of additional soil at harvest comes the potential for higher numbers of clostridia spores to be ensiled with the forage.

The challenge with interpreting ash content of fermented alfalfa haylage is trying to determine a “cause-and-effect” relationship versus a “result.” Specifically, did the higher ash content lead to a higher tendency for a “clostridic time bomb” event or was the higher ash content simply a result of increased DM loss due to secondary clostridial fermentation?

In either case, clostridia will continue to consume water-soluble carbohydrates, which should be preserved and will be beneficial to high-producing cows. Although Figure 3 shows the association between butyric acid concentrations and ash content of legume samples, it does not confirm a “cause-and-effect” versus a “result” relationship.

Buffering capacity

Alfalfa has a natural buffering capacity primarily due to protein and Ca content. This buffering capacity requires additional production of lactic acid in order to drop the pH of the fermented forage to a stable, terminal pH. Solely relying on the epiphytic (naturally occurring) lactic acid bacteria to drive lactic acid production and the concurrent drop in pH, potentiates a “clostridic time bomb” event.

Critical control points

-

Critical control point #1 – Target DM for alfalfa haylage ideally should be 38 to 42 percent (58 to 62 percent moisture) in order to minimize the likelihood of a “clostridic time bomb” event, but realize that actual DM going into the bunker or pile realistically will fall between 35 and 45 percent (55 to 65 percent moisture) for this target.

Nonetheless, by targeting 40 percent DM, the vast majority if not all alfalfa harvested for silage will be at a moisture detrimental to widespread growth of clostridia.

- Critical control point #2 – Apply a research-backed bacterial inoculant designed to inhibit clostridial fermentation in order to capitalize on the limited water-soluble carbohydrates and drive fermentation toward producing lactic acid and a low terminal pH.

Some of the highest-quality alfalfa haylage we saw in Wisconsin was produced by Steve Abel at Abel Dairy Farms LLC, between Eden and Fond du Lac, Wisconsin. Abel’s alfalfa haylage plan includes timely cutting and wilting.

Alfalfa is conditioned to have less forage in contact with the soil during wilting. Obviously, best management practices for alfalfa for various locations and environmental conditions during harvest may require modifications to this recommendation, especially if a re-wetting event is expected.

Abel credits several key management factors as helping him to avoid the “clostridic time bomb,” including communication and decision-making.

“Each piece of our farming equipment has a two-way radio for rapid, on-demand communication among everyone involved in the haylage-making and storage process,” says Abel.

From a decision-making perspective, someone has to be empowered and willing to make the tough decisions on when to start and stop if moistures are outside the ideal range. “There are two of us who make the decisions on when to start and stop.

That way there is shared blame when things don’t go right,” Abel said jokingly. He continued, “The bottom line is someone has to make the tough decisions and the owner should be one who is directly involved even if it is a custom harvest situation.” PD

The authors would like to acknowledge Dr. John Goeser and Rock River Laboratory, Inc.’s contribution to this article by providing data and figures.

Keith Bryan, Ph.D., is the technical services manager and John Kurtz is North America cattle business manager, animal health and nutrition. Both are with CHR Hansen Inc.

References omitted due to space but are available upon request. Click here to email an editor.