More milk and components from each kilogram of feed is the basis for the feed efficiency equation. In countries where production caps have not been set, this idea resonates well since maximized production most often translates to additional revenue for the dairy.

But for dairy producers working within a quota system, what’s the reward for maximizing herd production?

Improving efficiency goes beyond “just more milk.” When you are able to produce more milk and components from each kilogram of feed, fewer animals are needed to meet production goals on the dairy. This reduces input costs – including feed bills, veterinary costs and fixed expenses – while generating additional profits per cow.

Putting efficiency in action

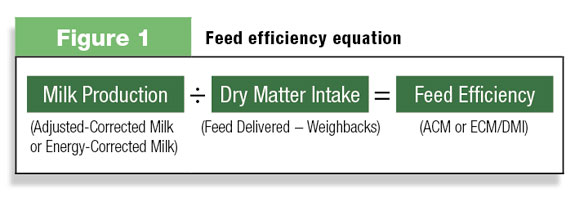

Figure 1 explains the basics of feed efficiency. The equation takes into account production and dry matter intake to generate a numerical value for feed efficiency.

There are two milk production numbers that can be used in the feed efficiency calculation:

- Adjusted-corrected milk (ACM) removes variability in the milk production calculation by adjusting for days in milk of the herd, fat test of the milk and percent of heifers in the herd. ACM will likely be the best number to utilize for monitoring overall herd efficiency.

- Energy-corrected milk will likely serve as the best parameter for monitoring efficiency at the pen level. When evaluating individual pens or groups of cows, days in milk and percent of heifers will likely be similar.

The feed efficiency equation must be tracked regularly to be meaningful and results should be compared to internal, historical herd data rather than other dairy operations.

One herd may be able to improve efficiencies by a larger percentage while another makes the same changes and realizes a different end result. Aim for a feed efficiency in the range of 1.4 to 1.8, meaning for every kilogram of dry matter consumed, 1.36 to 1.75 litres of milk is produced.

There are multiple factors to consider as you calculate feed efficiency. Make sure DMI accounts for feed consumed, which means subtracting the amount left over in the bunk and feed losses during delivery.

To truly evaluate feed efficiency, controlled studies measure it on a per-animal basis. Since this can be difficult and costly on commercial dairies, measure feed efficiency on a pen basis and review your findings weekly.

Translating efficiency to dollar signs

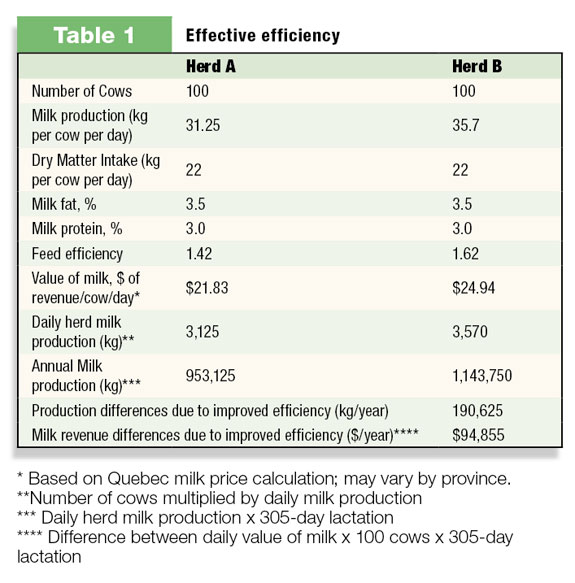

To demonstrate just how effective efficiency can be on long-term profitability for Canadian dairies, Table 1 outlines two herds of similar size with the same dry matter intake (DMI). The only difference between the herds is that one produces 4.45 additional kilograms of milk per cow per day.

As the table shows, Herd B generates an additional 190,625 kilograms of milk per year from the same amount of feed as consumed by Herd A. Because of the improvements in feed efficiency, the same amount of milk can be produced in Herd B with 12 fewer cows – only 88 animals rather than 100.

Improved efficiency ultimately translates to increased productivity per animal and significant reductions in input costs to generate the same revenue.

Reap the benefits of improved efficiency

Once you have calculated feed efficiency in your herd, the next step is to understand what the data tells you and then make an action plan to make improvements to this value.

- Use efficiency as a guide. Because feed efficiency can be so variable, use the calculated value as a guide, not as the only measurement of ration quality and herd performance. If you hit an acceptable range, your herd meets the goal for feed efficiency standards.

Remember that individual pens will vary outside of this range based on weight loss or gain and milk production levels. Monitor feed efficiency values at least monthly to observe how the herd is responding to the ration.

- Measure feed efficiency consistently. Measure feed efficiency the same way every time you calculate it. Use the same milk production value, collect feed refusals at the same time and have the same person determine refusal amounts and dry matter to get an accurate reading.

- Calculate efficiency for specific cow groups. Feed efficiency values will vary depending on stage of lactation. High-producing cows are a good group to closely monitor, as they are in peak performance and use their diet, rather than fat reserves, as their main nutrient source.

Fresh cows may have feed efficiency of 1.8 or greater because they are mobilizing body reserves and eating fewer kilograms of dry matter. On the other hand, cows in late lactation not producing high milk, but regaining bodyweight, can have efficiencies as low as 1.3.

- Monitor forage quality. Feeding high-quality forages can directly influence feed efficiency. High-quality forages often move through the cow faster, which makes other feeds, like straw, critical in order to slow the passage rate and improve feedstuff utilization.

- Focus on feed ingredients. Specially formulated feed ingredients have been created to increase rumen microbial growth, allowing for additional breakdown of each kilograms of feed and a higher feed efficiency value.

Beyond that, there is also recognized value in providing feeds intentionally designed to bypass the rumen in order to supplement what the cow cannot deliver through fermentation.

Regardless of milk production quotes, feed efficiency delivers a multitude of benefits for your dairy operation. More milk from fewer animals translates to greater profit potential and success for your dairy operation. PD

References omitted due to space but are available upon request to editor@progressivedairy.com .

* Based on Quebec milk price calculation; may vary by province.

**Number of cows multiplied by daily milk production

*** Daily herd milk production x 305-day lactation

**** Difference between daily value of milk x 100 cows x 305-day lactation

-

Elliot Block

- Senior Manager of Technology

- Arm & Hammer Animal Nutrition

- Email Elliot Block