Why work hard and spend money to produce a quality product – and then throw a quarter of it away? That is what many producers do by not investing in quality storage options for their harvested hay.

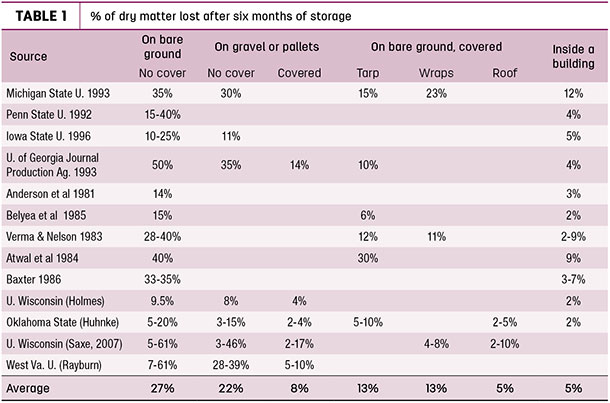

Various options exist for storing hay bales, whether small squares, large squares or round bales. The lowest-cost alternative is simply leaving them on bare ground with no covering. However, some researchers have found bales can lose as much as 30 or 40 percent of their dry matter after just six months when stored this way (Table 1).

Click here or on the image above to view it at full size in a new window.

Ground covers

If bales are stored on bare ground, they should at least be on a slope that is well drained. A fairly low-cost option is to spread a layer of crushed rock or gravel on the surface area where bales will be stored. This will reduce the amount of moisture that seeps into the bales over time.

An even better base can be provided by arranging used wooden pallets. These not only form a moisture barrier, they also allow air to circulate under the bales, reducing storage losses by two-thirds or more. The cost of pallets can vary widely depending on the source.

Top covers

Bales can be protected even further by covering them with a plastic tarp. This choice is more economical when bales can be stacked several layers high. Uncovered bales should not be stacked, however, as this prevents water from running away from them and keeps them from drying out.

Low-cost plastic requires a minimal investment but may not be reusable. Most costly thick plastic or canvas tarps can be used for multiple years.

Individual covers have become more economical and more popular in recent years. Bales wrapped with plastic netting or sleeves shed water better than those wrapped only with twine. Plastic bags do a very good job of preserving hay quality but require investment in bagging equipment.

They are more expensive but may be cost-effective for very high-quality forage. Bale wraps and bags generally can be used only once, however, and create a disposal problem.

Storage buildings

For higher-quality hay, investing in permanent storage facilities may be the most economical choice when reduced spoilage losses are taken into account. This can range from refurbishing an existing barn or shed to erecting a pole barn with a roof but no sides to building a completely enclosed new building.

These options involve a higher initial cost, so should be undertaken only when a consistent volume of hay is likely to be produced over a longer period of time.

The cost of buildings for hay storage depends on the interest rate associated with the initial capital investment and the expected life of the structure. The Farm Service Agency offers loans at below market interest rates (currently under 3 percent annually) for hay storage structures.

Maintenance costs should be minimal, especially in the early years. Existing buildings often can be refurbished at a very low cost; however, they may offer less convenience for getting bales into and out of storage.

Other considerations

Labor requirements will vary widely by system. Simply moving bales to the edge of the field and dropping them on a surface requires minimal time. Covering them with a tarp will add some more time, especially for an individual working alone.

Moving bales to a storage building and stacking them inside will require the most labor, and the effort will be duplicated when they are removed. What value to put on the producer’s own labor is arbitrary and may depend on what other activities need to be performed during forage harvesting season.

Livestock producers who need a certain quantity of hay each year to meet their animals’ nutritional needs have an extra consideration. Storage systems with a high dry matter loss will require them to devote extra acres to hay production to meet the needs of their herd or flock.

Decision tools available

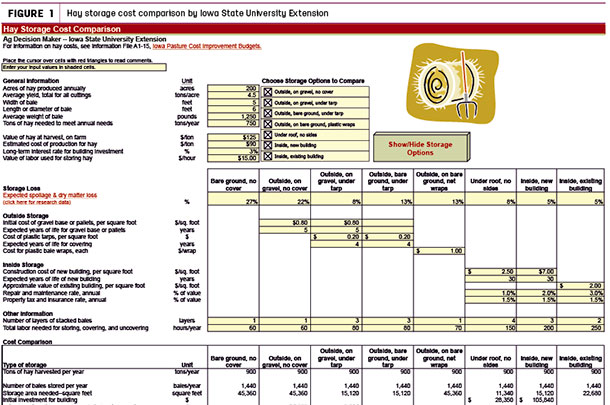

At least two spreadsheets are available for analyzing the costs of various hay storage options. The Ag Decision Maker website maintained by Iowa State University Extension and Outreach offers “Hay Storage Cost Comparison,” which compares up to eight storage choices.

It takes into account the annual costs for covers and labor as well as the initial cost of surfaces and buildings. It also factors in the value of storage losses to compute an overall storage cost for each system.

In addition, the user can specify the annual forage needs for the farm or ranch, and the spreadsheet will calculate the total cost of production for meeting that need after adjusting for spoilage loss. This spreadsheet can be downloaded from the website. An example is shown in Figure 1.

Click here or on the image above to view it at full size in a new window.

Users should input values for their own situations as much as possible, however.

Brian Holmes of the University of Wisconsin Extension Team Forage has developed a slightly different spreadsheet called “Comparing Round Bale Storage Costs.” It compares storing hay on bare ground, a macadam surface and wooden pallets, with and without cover, as well as in a storage building.

Storage periods of both six months and 12 months are analyzed. Look for a link to this spreadsheet under the Hay Storage Sizing and Management section of the Team Forage website. ![]()

References omitted but are available upon request. Click here to email an editor.

-

William M. Edwards

- Retired Extension Farm Management Specialist

- Iowa State University

- Email William M. Edwards