Some of the reasons, depending on location, include feed during critical times, flexibility of harvest schedule and palatability of the product, but mainly it allows resting of pastures. While there are many advantages, there are also some challenges. Before deciding to embark on this preservation method, let’s take a look at some of these pros and cons.

What is baleage?

“Round bale silage” is technically a high-moisture forage preservation method with forage cut and wilted to 45 to 55 percent moisture. Baleage is a two-step process, with baling and immediate plastic wrapping of the bales. It is a way of “pickling” hay through conditions that are anaerobic (elimination of oxygen), with low pH and production of lactic acid – just like in bunk silage.

Why baleage for the grazing system?

If we look at the forage production calendar in the Upper Midwest – for areas like Wisconsin, for example – we have six to seven months where forages cannot grow, which is very different from areas in the transition zone or central-eastern U.S. Additionally, we have springs with very rapid growth and summers where cool-season forages experience a slump due to warm temperatures.

Baleage, in these cases, provides feed supply when forage is not abundant. Baleage also captures excess forage during spring growth. It is less dependent on weather compared to hay. And more importantly, baleage allows pastures to rest for re-stocking the proper energy reserve.

The process of making baleage

Field site selection for storage

Baleage storage in the field would ideally be on sod, free of stubble and close to the feeding area. Storing bales is the last thing you will do but is among the first things to consider, as the whole process will be affected by where the wrapped bales rest.

Moisture

Wilt the forage to 45 to 55 percent moisture. Forage that is too dry will cause molding, and forage that is too wet will lower the quality in addition to creating a situation of insufficient dry matter per bag and potential clostridium problems. In Wisconsin, for example, wilting will require cutting one day and baling the next, whereas in southern locations, such as Coastal Plains in the U.S., this is achieved in just a few hours.

Baling twine

Use plastic twine, plastic net or untreated sisal twine for baling. Treated sisal twine damages the plastic film.

Plastic wrap and number of wrapping layers

The wrapping film is plastic polyethylene pre-stretched 50 to 70 percent. Film will vary in thickness and color. Plastic may be white or black, but white film is commonly used because it reflects light better than black. The key to successful wrapping is the number of layers.

Use at least six to seven wrapping layers with an overlap of 12 to 18 percent. The use of more layers will keep air out, will keep higher quality and will reduce holes or damage by wildlife. If possible, use thicker high-quality plastic.

Time to wrapping

One key to making successful baleage is to wrap the bale quickly with plastic after baling. Delaying the wrapping will heat the wet bales and drop hay quality due to heating (referred to as the Maillard reaction). The recommendation is to wrap bales within 24 hours to avoid the initial bale heating. Delayed wrapping will also increase pH and compromise the fermentation process. A good policy is to cut only what you can bale and wrap by the next day (or whenever you have the target wilt). In this manner you are not left with excess unwrapped wet bales that are heating up and losing quality.

Types of bale wrappers

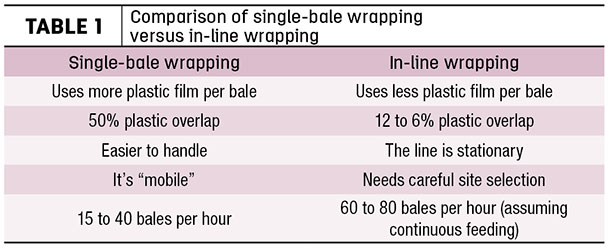

Baleage can be done in single bales or with in-line wrapping. Table 1 provides a comparison between the two.

Baleage cons

While baleage provides many benefits, there are some associated challenges.

- Plastic disposal: Dumping or discarding plastic can be challenging for many farms. Plastic burning is associated with toxic gas production; a 2015 University of Wisconsin Extension survey showed landfill and burning as the main disposal methods.

It also showed a substantial number of respondents willing to pay a fee for plastic bale and transport off property. Recent free agricultural and silage plastic collection programs are available and on the increase in Wisconsin and other states.

- Short-term storage: While baleage is an excellent preservation method, over time (greater than nine months) bales become difficult to handle. Bales will conform to the ground or “squat,” making handling difficult. Also, plastic will tend to disintegrate, and it is not recommended to keep baleage for more than two summers.

- Baleage weights are heavier than dry hay due to high moisture content.

- Transportation options are limited with baleage.

- There is an additional expense for a bale wrapper.

Baleage for the grazing system can impose some challenges, but the advantages may outweigh many of them.

In summary, baleage for the grazing system provides feed during critical times, flexibility of harvest schedule, more palatable and higher quality feed compared to hay, and most importantly, is another resource that allows pastures to

rest. ![]()

PHOTO: Baleage for the grazing system provides feed during critical times, flexibility of harvest schedule, more palatable and higher quality feed compared to hay, and most importantly, is another resource that allows pastures to rest. Photo by Mike Dixon.

-

Yoana Newman

- Extension Forage Specialist

- University of Wisconsin – River Falls

- Email Yoana Newman