The process relies on the fermentation of simple sugars to organic (lactic) acids by lactic acid bacteria (LAB) and is impacted by several variables like temperature, moisture, degree of anaerobiosis and the population of micro-organisms that naturally colonize the plant.

Adverse conditions such as excessive plant moisture or dryness, air and water leakage, and pest infestation can lead to reduction of nutritive value, growth of undesirable micro-organisms such as yeasts and molds, and potentially, mycotoxin production.

I see molds in my silage; do I also have mycotoxin contamination?

A common belief is that the presence of molds indicates silage is aerobically deteriorating. The main reason is: The mycelium of the molds can be seen by the naked eye. In most cases, spoilage is actually initiated by yeasts, such as Candida and Pichia, as oxygen penetrates the silage mass during feedout.

They utilize residual sugars and lactic acid to grow; consequently, the pH rises as the lactic acid is consumed. Only then do molds – and other opportunistic microbes – appear. Aerobic spoilage is already well advanced and significant losses (e.g., up to 40 percent of the dry matter) have already occurred.

Mold growth can cause palatability issues and respiratory problems or reduce animal performance, and some molds can produce mycotoxins under certain circumstances. Mycotoxins are low-molecular weight compounds harmful to humans and animals.

While they are often concentrated in the visible colored patches where molds have formed spores, they can also be produced in areas where mold growth is restricted and possibly not visible.

Contaminated feed is a major source of mycotoxins, forming a threat to animal productivity, health and fertility. Some toxins can also be carried forward into the human food chain.

Visibly moldy silage should be discarded regardless of the presence of mycotoxins, but remember that the feed may not be safe even if there is no visible mold growth.

Also, hazardous levels of mycotoxins may accumulate in the field and be brought into the silo. Therefore, regular monitoring of the fields during growing season is imperative, as is applying any necessary fungicides.

Fresh forage should be sampled and analyzed during silo filling to serve as a baseline on which mycotoxins might be present and at what levels – but bear in mind that mycotoxins tend to occur in concentrated “hot spots.”

A confounding issue is: Feedstuffs can be contaminated by several different molds and each may produce several mycotoxins if the circumstances are appropriate. Currently, little is known about the synergistic interactions among mycotoxins.

Mold growth during storage

Ensiling relies on physical, chemical and biological interactions to maximize the efficiency of fermentation and retention of nutrients and dry matter. Anaerobic conditions and acidity (low pH) maintain stability of the stored silage.

Well-maintained and managed silos with silages produced from top-quality forages are less susceptible to mold issues.

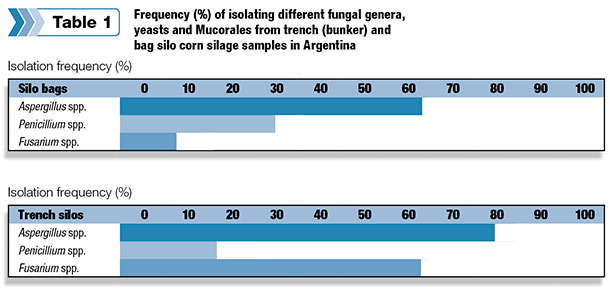

The type of storage structure also has an impact on mycotoxin contamination (Table 1).

Oxygen limiting/concrete towers and bag silos tend to have lower levels of mycotoxins compared to bunker and pile silos, since the latter two are more prone to oxygen infiltration. The molds that produce mycotoxins of agronomic concern are aerobic.

Oxygen limiting/concrete towers and bag silos tend to have lower levels of mycotoxins compared to bunker and pile silos, since the latter two are more prone to oxygen infiltration. The molds that produce mycotoxins of agronomic concern are aerobic.

They require oxygen to grow, so oxygen availability is the key factor for determining mold development and mycotoxin production. The other prerequisites – temperature, moisture and substrate – are all mostly “standard features” of any storage system.

Inspect silos regularly during the storage phase and repair as necessary. Silo bags and plastic covers can be damaged by animals, people, weather and farm machinery. The concrete walls of tower silos are porous to air, and the silage acids produced can increase this porosity.

Water ingress can also be detrimental to silage quality. Soluble nutrients and fermentation acids will be lost, leading to higher pH. Water can also bring in oxygen to opportunistic spoilage microbes that, along with higher pH, will accelerate deterioration, potentially leading to mycotoxin production.

‘Storage’ mycotoxins

The most important mycotoxigenic funguses are Aspergillus, Fusarium and Penicillium, which can all be found in silage. Penicillium species and A. fumigatus are considered “ensilage-derived molds,” while Fusarium species A. flavus and A. parasiticus are considered “field-derived molds.”

Aspergillus flavus has a yellow/green color from the spores it produces and is known to produce carcinogenic aflatoxins. Transfer through to milk can be as high as 2 percent. This toxin is particularly important in warmer regions as production requires warm, (85ºF) humid conditions.

Species of Penicillium produce spores that give a green/blue “dusty” appearance, and several have been isolated from silages. P. roqueforti and P. paneum are able to grow under anaerobic and acidic conditions, and the mycotoxins they produce can be found in materials that do not appear moldy.

These molds may contaminate silage with at least five different mycotoxins.

Some species of Aspergillus and Penicillium can produce ochratoxins, which can be at least partially detoxified by rumen micro-organisms. The most commonly found form is ochratoxin A, with barley the most frequently reported source.

Can lactic bacteria inoculants help?

High-dose rate Lactobacillus buchneri 40788 (400,000 colony-forming units per gram) has uniquely been positively reviewed by the FDA for increasing aerobic stability, subsequently reducing opportunistic secondary mold growth at feedout. In some studies, this has also resulted in significant reductions in mycotoxin levels.

Recently, the potential for some lactic bacteria to sequester mycotoxins in silages has been studied.

French researchers tested the ability of 29 strains of lactic and propionic acid bacteria to remove Fusarium mycotoxins in culture medium and in acidified corn infusion. Three strains of LAB were able to bind up to 75 percent for zearalenone in corn infusion acidified at pH 4.

Researchers at University of Florida – Gainesville studied the capacity of certain LAB to bind aflatoxin B1. All strains bound the aflatoxin, but the degree of binding varied with LAB strain, population and viability, and pH.

Managing mycotoxin-contaminated silages at feedout

There is no practical, economical method for complete detoxification of feeds. Prevention of yeast and mold growth is the best way to reduce spoilage losses and the presence of mycotoxins in silage. Therefore, all recommended agronomic and silage management best practices should always be implemented.

If molds are present and contamination with mycotoxins occurs, discard all visibly moldy silage. Material contaminated with mycotoxins but not visibly moldy should be at least diluted to decrease the toxin concentration to a level safe for feeding.

Clay-based materials such as bentonite, zeolite and calcium aluminosilicate may decrease the effects of aflatoxin contamination, while yeast cell wall extracts – mannan oligosaccharides and glucomannans – can reduce toxicity due to the Fusarium toxins T-2, DON and zearalenone.

These products do differ in efficacy due to yeast source and processing technologies, and do not bind all mycotoxins equally, so check efficacy data.

Like most things in life, prevention is better than (attempted) cure. ![]()

-

Renato Schmidt

- Forage Products Specialist

- Lallemand Animal Nutrition

- Email Renato Schmidt