In this natural cycle, we are going back to the long-term average temperatures. The earlier-than-normal springs the Northeast had been getting are now reverting to what we used to have a number of years ago: cooler, later springs.

This year is approaching the 30-year average of 1965-1995. Don’t panic; we survived then and will survive now if you adjust to the new (old) normal spring.

With this change comes a change in harvest of our first-cutting forages. The cool temperatures actually allow you to harvest higher-digestibility forages from your grasses and legumes. Cool night temperatures reduce the respiration of digestible components such as sugar and starch which then accumulate, increasing the overall digestibility of the forage.

The other factor changing is when your forage is ready to harvest. Jumping too early will give up a tremendous amount of yield. For example, we harvested winter triticale at stage 8 on a Thursday and again at stage 9 on the following Tuesday in replicated plots.

In that five days, we gained 32 percent yield increase with no quality loss. The cost per acre of harvest changes very little with changing yield.

The flip side is that too low a harvest yield makes a very expensive cost per ton of forage and directly reduces your profit. The opposite, being too late, will reduce feed value and the level of milk production it will sustain.

There is an optimum time of harvest. The key point is: Date is completely irrelevant as to when your first-cutting hay crop is ready. Your individual fields should determine when you should start harvest, using your alfalfa as a predictor. The height of alfalfa can predict when it and grass fields, in your local climate, condition and individual field, should be cut.

Dr. Cherney of Cornell University developed this practical, accurate system that can be found on the web (Grass Management Tools).

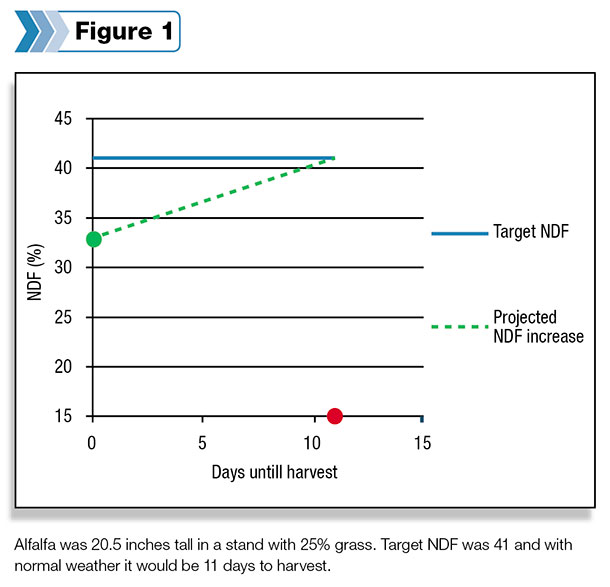

For the alfalfa-grass estimator (Figure 1), you insert the alfalfa height, percent grass, NDF target and the weather (normal, hot, cool), and it will tell you how many days until that field on your farm under your conditions is at peak quality for harvest. For example:

- If the alfalfa is 12 inches tall, the stand contains 50 percent grass, and the target NDF is 45, under normal weather it will be 13.5 days to harvest. If the weather switches to hot, then you have 11.5 days to harvest.

- If the above stand is 80 percent grass with normal weather, and the alfalfa is 12 inches tall, then you have 1.5 days before it is at peak quality.

- That same field with the same height alfalfa and normal weather, if it is 80 percent alfalfa, would not be ready for another 28 days.

On this one farm, with fields from 80 percent grass to 80 percent alfalfa, you have a 26-day interval between the first field to cut and the last – but all are at the same high-quality forage.

For the farms with rolling fields and variable soil types, this can allow for an even wider harvest range without compromising forage quality.

The first fields to reach peak would be mostly grass, on a south or east slope with medium- to well-drained soil. The last fields to be ready would be mostly legume on a north or west slope with less-than-ideal drainage.

Thus we come to the biggest obstacle to using this system: your head. Farmers are used to starting with the field by the barn (in case something breaks) and then working down the line of fields in physical order. They then jump to another farm and start there.

A 50-cow farmer had his daughter list all the fields, the percent legume or grass, and the height of the legume. They then used Dr. Cherney’s calculator to determine when each was ready. The list was then sorted in how soon it was at peak quality, which gave them their field sequence cutting schedule.

The added bonus of this is that if adverse weather messes up the schedule, you can skip over the fields that have gone by and continue with those that are of peak quality.

The ones that were skipped can be harvested last for dry cows or heifer rations. The upshot was that they had a two- to three-week harvest window for peak quality. They started much earlier than expected yet had good quality on the last field.

Dr. Cherney’s other two estimators, grass NDF and alfalfa NDF, will give you a calculation on the impact of changing your cutting height and its impact on yield. For the alfalfa NDF calculator, you can adjust the height of the mower and reduce the ash.

At that point you are also reducing yield slightly. Dr. Cherney’s calculator will tell you how much you are reducing yield. As you are leaving behind the poorest digestible portion of the plant, the higher mowing can increase your forage quality at the same time.

Thus if weather delays your harvest, you can recover forage quality by cutting higher and leaving slightly more yield (of poorly digestible material) in the field.

The same works for the grass NDF estimator. Unfortunately, raising the cutterbar has much less impact on improving forage quality than alfalfa. What the grass NDF calculator does not take into account is what many farmers and researchers have found: Raising the cutterbar on grass leaves more photosynthetic surface for more rapid regrowth.

Going from 2-inch cutterbar height to 4 inches, you leave 400 pounds (13 percent) of the yield and almost as much dirt behind, but you gain in speed of regrowth of the grass and total yield for the year.

Using the predictor system to determine what fields to harvest first allows you to harvest early and later fields at peak quality. We start with winter triticale at flag leaf and continue right on to straight grass fields, then to mixed grass/legume with increasing legume and finish with all-legume fields.

Thus you have high-quality forage from all fields, even though the harvest may have started a week or two later for some fields. FG

—Excerpts from Advanced Ag Systems Crop Soil News enewsletter

Thomas Kilcer

Certified Crop Adviser

Advanced Ag Systems

Email Thomas Kilcer