For some, corn silage harvest lasts one day. For some it will be one week and yet others one month. No matter the timeframe, intense management is required.

Let’s keep things in perspective; if you have ever planned a day trip with your family, think about all the preparation it took to pull it off. Now think about a week-long or month-long family trip; did you plan your time away, your lodging, meals, transportation?

Maybe your spouse did all the planning. Either way, your team had to plan in order to pull off a great family trip. Think about your corn silage harvest the same way.

You know what you want from your harvest; now you need to gather up your teams that will get you to your goal. Your farm team has worked the dirt, planted the seed, watered and weeded the plants, and now harvest is imminent.

Consider getting your harvest and nutrition teams together to plan the harvest, storage and feedout expectations at least a few weeks prior to harvest – perhaps during mid-silk stage, which gives roughly 30 days to nail down your goals and a plan to reach them.

Go over things such as what percentage dry matter (DM) you expect, when the last irrigation should be finished, where you’re going to store the feed, and what size the pile needs to be to safely feed an appropriate amount of feed each day.

How will you achieve 15+ # DM per cubic foot? Who will monitor quality? Who will coordinate the aspects that need to be monitored, like DM, processing, chop quality, silo fill rate, pack or pile quality, and pile size and shape? (There are tools available for these decisions online.)

Be creative and commit to the entire 12-month process. If you are in a part of the world where irrigation time is left to Mother Nature, do your pre-planning in all other areas. Don’t wait for someone else to lead your harvest. Ultimately, it comes down to you. You own the business, so you own the harvest.

Second, we want to talk a little about kernel processing. As mentioned above, kernel processing will help or hurt your feed cost, and ultimately, your bottom line.

It’s your choice. The evolution of processing has been interesting; five to 10 years ago, there were people who didn’t think processing was necessary or “worth it.”

Then we went from “Nicking the kernel is good enough” to “It needs to be pulverized and undetectable.”

From a nutrition and management perspective, pulverizing makes the most sense, since it allows for more complete starch digestion in the rumen.

Research has soundly established that as dry matter increases, so does starch in corn silage. As dry matter increases, we capture more starch in silage piles and bags, mainly because it doesn’t leach out.

Dry matter plays a role in processing quality, so it is important to make sure you observe the pile on a very regular basis and make adjustments with your harvest crew when necessary.

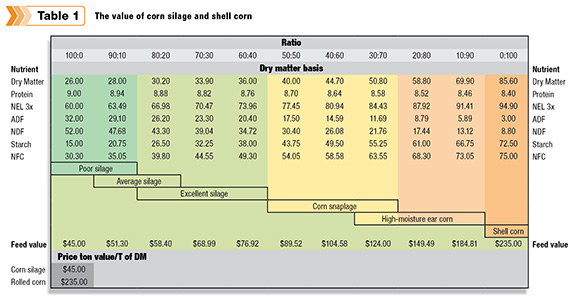

As dry matter goes up, the value of the silage product also goes up simply because you are able to capture more real product and less water.

In addition, the maturity of the plant provides for potentially higher feed value. Feed value is the term used for the actual value of the feed when it is available in the TMR, not in the field, bunk or bag. It is the term used relative to all other feeds that go into the TMR and the market cost of replacing it.

The correlation between dry matter and high quality is not linear. If you are making silage, it’s a bell-shaped curve: poor on both ends of the dry matter spectrum with a sweet spot in the middle (33 percent DM).

However, as we move progressively through the options with a corn crop, from poor silage to excellent silage (further on to earlage, snaplage, high-moisture corn, shelled corn and ground corn), the starch continues to linearly increase as dry matter increases because you are removing the non-starch (stalk or stover portion).

Table 1 shows the relationship of the whole-corn plant options at harvest and as-fed value (feed value).

Variety and maturity also play a role in total starch availability as well as processing potential.

Modern harvesting equipment should be able to adjust in minutes or seconds either electronically or manually at the processor to accommodate variables in the crop.

Processor spacing should not be one of those things you set and forget; it’s an ever-adjusting feature that should be used as a tool to reach an optimal processing score of 70-plus percent passing through a 4.75 mm screen when dried down.

Equipment wear, harvest conditions, variety and dry matter are just a few factors that play a role in how frequently and to what degree adjustments are made.

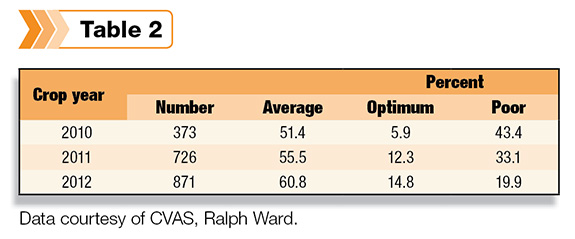

In the last three years, the number of poor-quality processing scores have been cut in half, from 43.4 percent of the samples analyzed to just 19.9 percent of those samples run by Cumberland Valley Analytical Services (CVAS).

At the same time, the percentage of samples testing in the optimal range have more than doubled from 5.9 to 14.8 percent (Table 2).

This is encouraging to know and should motivate more growers to participate in fully understanding what processing they currently have and what potential is out there.

Nicking or cracking is not considered high-quality processing any more – not today, not for the modern dairy business.

It’s not acceptable. In a time when margins continue to be a focal point and where profits are tighter than decades past, silage (in particular corn silage) is the single-biggest opportunity for increased profitability for the vast majority of progressive dairymen.

In an era where 5 percent shrink on grains is not acceptable, but a 20 percent shrink on corn silage goes undetected, we have opportunity for higher profits through higher levels of feed management.

Typically, silage will make up 30 to 50 percent of the ration; one ingredient making up that percentage should be the focal point for a very intense level of management.

Cows crave consistency, and we should always focus on creating a TMR that is consistently sized, mixed and delivered.

Every nutritionist strives to achieve silage that complements other available feeds. As a nutritionist, it is my responsibility to advise and recommend economical research-based suggestions to increase profitability.

Consistency in chop length and kernel processing are two key areas to maximize the value of silage. Optimally processed silage will be completely destroyed, yet consistently sized.

Stalk pieces will be consistently sized and filleted open, with kernels exploded such that 70-plus percent of the starch will pass thru a 4.75 mm screen.

There are products on the market that make unsubstantiated claims; beware of spending hard-earned dollars on these claims.

If you strive to own the harvest, remember: Harvest only happens one time a year; plan to make it perfect, get your team involved early and often. It’s not too early to start planning for next year’s harvest.

Processing is important, ensure through regular testing that you are achieving 70-plus percent corn silage processing score.

Finally, cows crave consistency. Don’t get caught in hype over unsubstantiated “new technology.” Focus on what’s proven and works in the cow. It’s time to own your harvest. FG

Luciana Jonkman

Nutrition & Management Consultant

Progressive Dairy Solutions, Inc.