Large sections of the United States where dairy producers reside were inundated with excessive rain. Early-season precipitation resulted in flooding, delayed planting and made harvesting dry hay nearly impossible. In the summer, the timely rains were welcome to help maximize corn growth, but small-grain and alfalfa silage production was a battle against the forecast. Then, late-season precipitation made corn and corn silage harvesting a muddy mess. 2019 will certainly remain in our memory for a generation or two.

With 2019 in the rearview mirror, we should now take time to review the 2019 silage season. First, what can producers expect as they open their silage piles? Second, how does 2019 compare with the 2018 crop? Finally, what can we learn from 2019 to use in 2020 to improve our forages?

Every fall, our laboratory services works with Dairyland Laboratories to summarize their massive database to validate our database and also give customers a wider look at the yearly forage quality.

Corn silage samples

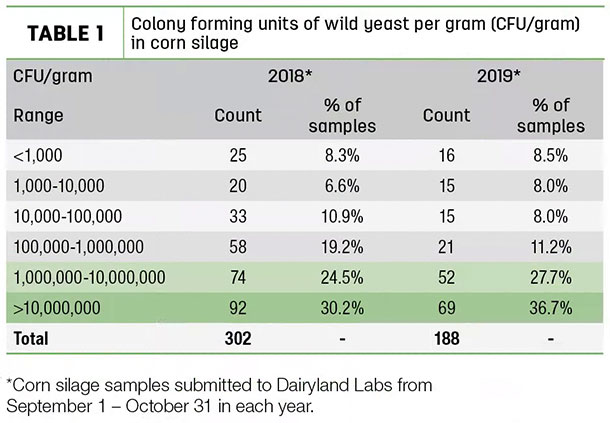

Early evaluation of data generated since harvest appears to predict that forages used in 2020 will again challenge producers. Corn silage samples submitted to Dairyland Laboratories from Sept. 1-Oct. 31 are arriving with higher levels of wild yeast than the same period in 2018 (Table 1).

Sixty-four percent of the samples contain more than 1 million colony-forming units per gram (CFU/g). In 2018, 55% of the samples were over this threshold. Why is 1 million a concern? Dr. Limin Kung reported that when animals consume spoiled silages, the exact causes of reduced intake and/or performance are not fully understood. Nevertheless, feedback from the field suggests producers often have problems when the numbers of yeasts are more than 1 million per gram of silage.

Based off this data, when we feed the 2019 crop in 2020, we are likely to encounter ration heating, as was common in 2019. When wild yeast in silage are exposed to oxygen, they become active and begin the process of feed degradation. The major species of these yeasts include those of candida, hansenula, pichia, issatchenkia and saccharomyces. As they grow and multiply, wild yeast that degrade lactic acid in the presence of air are the primary microbes that cause spoilage in silages.

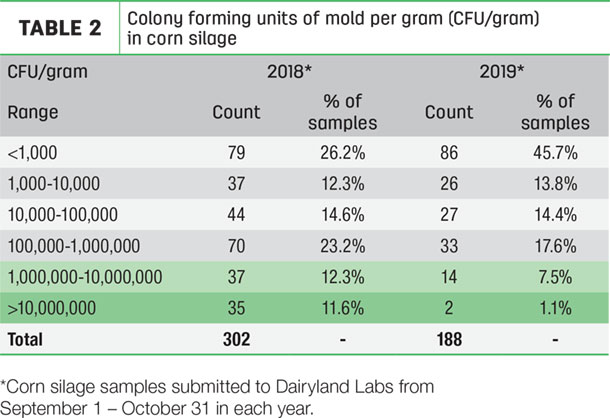

Along with wild yeast, Dairyland completes evaluation of mold in forage samples. Penn State University provides an on-line publication that outlines the feed risks for various mold spore counts. According to their guidance, feed with mold counts over 1 million CFU/g should be “fed with caution,” and the energy value of the feed likely has 5% less energy than feed without this level of mold. The data generated by Dairyland Laboratories indicates corn silage samples in 2019 have less mold than silage in 2018 (Table 2). A bit of bright light following this challenging year!

Just remember, however, these data should not serve as a substitute for testing your own forages. Your individual growing conditions and harvest challenges could vary significantly from the average. Remember too, corn silage is only one component of a well-balanced total mixed ration (TMR).

Haylage samples

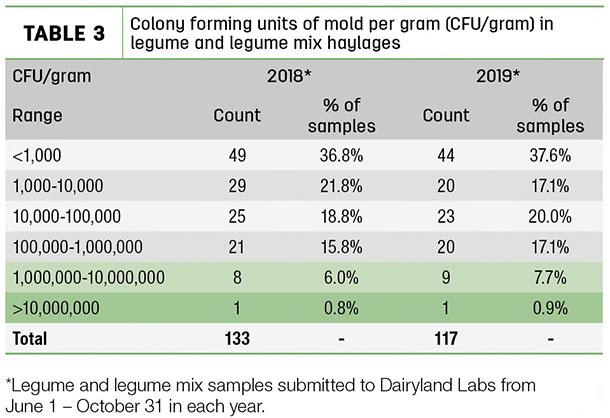

Dairyland also has been testing haylage samples since June 1, 2019. Compared with 2018 haylage samples, the 2019 samples submitted are showing slightly more mold, with nearly 9% over the 1 million CFU/g threshold and 17% between 100,000 and 1 million (Table 3).

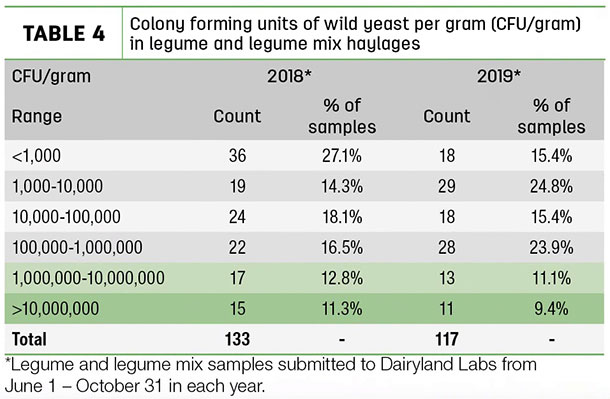

The wild yeast counts found in haylage samples are lower in 2019 versus 2018 (Table 4). Notice, however, the percentage of haylage samples found to contain 100,000 – 1 million CFU/g are much higher than 2018 and could present an issue with heating when haylage feeding begins.

Why the concern with wild yeast?

When discussing yeast, it is important to distinguish between wild and beneficial strains. Beneficial strains started out wild, but over time, manufacturers selected strains for their healthy traits. Feeding beneficial yeast is a good practice to improve herd health and performance.

Wild yeast strains have a large role in the deterioration of silage and ultimately in degradation of the ruminant ration. Once silage is exposed to air, the population of wild yeast begins to increase rapidly. The rate of yeast growth is accelerated during warm weather, but even during cold weather, wild yeast in most types of silage can increase dramatically from 100 to 10 million CFU/g in three days.

One of the well-known problems associated with wild yeast growth is the generation of heat. As yeast grow, they generate heat, and in summer months it is not uncommon to observe an increase of 10°-20°F inside the TMR after delivery to cattle. Detrimental yeasts may produce end products that might alter rumen fermentation. The direct consumption of spoiled nutrients may reduce performance, and the production of undesirable end products (e.g., mycotoxins) from further spoilage by molds and other organisms may also be a problem.

What can we do about TMR heating?

Summer temperatures and humidity increase the challenges posed by the growth of mold and wild yeast in the TMR. Along with heat and humidity, the growth of these microorganisms is fueled by nutrients in the TMR. As mentioned earlier, when these microorganisms grow and multiply, their metabolism generates heat. Thus, not only do the non-beneficial microorganisms reduce the nutrient density of the TMR, they also render the TMR less desirable to the cow as ration temperature increases.

The quality of a TMR can degrade quickly in summer conditions. Preventing secondary fermentation and its accompanying heat spike is important and is especially true if the forage or feed quality is already marginal.

Below are a few feed management practices to keep feed fresh during summer months:

- Feed twice per day. If possible, provide fresh feed when conditions are relatively cool. Consider offering two-thirds of the TMR in the late afternoon or early evening and one-third in the morning.

- Push up feed frequently.

- Carefully manage the face of your upright silo, bag or bunker. Removing 12 inches a day is recommended, and it is best to remove from the entire face.

- Use preservative products such as inoculants and organic acid blends at the time of harvest.

- Always use a thermometer to check temperatures. Feeling the temperature of the feed with your hand will not give you accurate results.

- Use highly concentrated, buffered, broad-spectrum mold inhibitors. Buffering the blended organic acids makes them less corrosive and much safer to handle.

If wild yeast is a problem, adding a blend of organic acids to mixed feed will be highly effective at controlling secondary fermentation and heating of the TMR. Single acid treatments often fail to control a wide variety of molds or wild yeast. For example, propionic acid will control some molds species but is ineffective on other strains. At the same time, propionic acid has limited efficacy on wild yeast.

A mold inhibitor with a higher total acid content containing acetic, benzoic and/or sorbic acids has demonstrated efficacy in controlling yeast growth. Multiple acid formulations are highly effective at controlling yeast.

Research conducted at the University of Delaware evaluated the use of a buffered blend of organic acids (propionic acid, potassium sorbate and sodium benzoate; 87% active ingredients) to reduce TMR heating and improve aerobic stability of corn silage. When silage was exposed to air, untreated corn silage was stable for 35.3 hours before heating. Silage treated with a blend of organic acids was stable for 49.3 hours. In addition, the application of organic acids reduced the peak temperature of the corn silage when exposed to air.

Summer weather is unpredictable. When labor is limited, feed quality is not optimal, and when conditions dictate, incorporating a premium mold inhibitor into the TMR can help protect your investment. ![]()

References omitted but are available upon request. Click here to email an editor.

Eugene Rodberg is the senior product manager with Kemin Animal Nutrition & Health – North America. Email Eugene Rodberg.