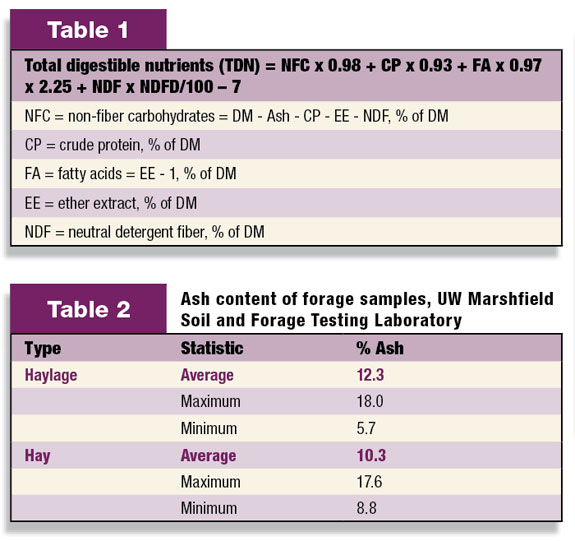

Now instead of estimating energy from acid detergent fiber, most estimate energy from the equation shown in Table 1.

When estimating energy from ADF, the ash content is unseen. Now that ash content is used to calculate the non-fiber carbohydrates (NFC), it is obvious that each 1 percent ash is 0.98 percent less NFC (and therefore TDN).

While some minerals are necessary for forage growth and may be beneficial to animals eating forage, we want to keep the ash content to a minimum because ash provides no calories and, in fact, ash replaces nutrients.

Ash in forage comes from two sources: internal, e.g. minerals like calcium, magnesium, potassium and phosphorus; and external, e.g. dirt, bedding, sand, etc.

The average internal ash content of alfalfa is about 8 percent and of grasses, about 6 percent. Additional ash in a hay or silage sample is contamination with dirt, sand, etc.

As shown in Table 2, a summary of ash content of forage samples submitted to the University of Wisconsin Soil and Forage Analysis Laboratory, the average ash content of haylage is 12.3 percent and of hay is 10.3 percent.

Assuming the silage is mainly alfalfa and the hay has a higher percentage of grass, forage samples are averaging about 4 percent ash contamination from external sources.

Note that some samples have been as high as 18 percent. This means some farmers have fed almost 1 pound of dirt for each 5 pounds of hay or silage!

Growers can do several things along each step of harvesting, storage and feedout to minimize ash.

Avoid harvesting lodged forage – as dirt often sticks to the downed forage when the soil is wet. This can’t always be avoided but can be reduced by planting varieties that stand better and by harvesting early in the spring to reduce the potential for a wind storm knocking the alfalfa/grass down.

Use flat knives on the disc mover – to pick up the least ash when mowing. Several disk knife types are available, as shown in the picture (below).

The flat knife at the left will pick up the least ash while the middle knife, at a 14-degree angle, will create some suction to pick up more downed hay and ash (when soil is dry).

Generally, those settings that pick up downed hay best also result in the most ash content when the soil is dry, so one needs to decide which is most important.

Raise the cutter bar of a disc mower – to lower ash and raise forage quality. Research suggests that alfalfa can be cut as short as 1.5 inches for maximum yield.

Each inch above this height will result in 0.5 ton per acre less yield for the year. (Though, if the mixture includes smooth bromegrass, orchardgrass, or timothy, cutting height should be 3 to 4 inches to avoid shortened stand life of the grass.)

However, lower-cut forage with a disc mower will have higher ash content when the soil surface is dry. Thus, raising the cutter bar lowers ash and raises forage quality while lowering the cutter bar results in greater yield.

Each individual must decide on the tradeoffs they want to take, but generally a cutting height of 2.5 to 3 inches seems best in most cases.

Keep windrow off the ground – starting with a wide swath and placing the cut forage onto dense stubble will eliminate harvesting a layer of soil on the bottom of windrows.

Putting hay into a wide swath also increases drying rate. The windrow should be high enough so that it can be raked or merged without the rake touching the ground.

Keep rake tines from touching the ground – this can be done if the forage is on top of stubble and the ground is level. Wheel rakes tend to incorporate more ash because they are ground-driven.

We should visualize that when we are raking and raising a cloud of dust, we are adding 1 to 2 percent ash to the hay.

Minimize moving hay horizontally to reduce stones and other ash. It is better to move two swaths on top of a third in the middle rather than to rake all to one side.

Using a windrow merger rather than raking will result in hay or silage with less ash content since the windrow is picked up and moved horizontally by a conveyer rather than being rolled across the ground. Merging can result in 1 to 2 percent less ash in the hay or silage.

Custom harvesters may be an option to consider if merged hay with lower ash content is desired, since mergers are expensive and may not be economical on many farms.

Store hay bales off the ground since bales on the ground pick up water from the soil and mold. This molding process causes loss of TDN and increases the ash concentration.

More important, the wet hay will pick up a layer of ash on the bottom if bales are sitting on the ground.

Store silage piles/tubes on concrete or asphalt to minimize ash contamination. Silage can be removed with minimal dirt contamination when conditions are dry, but dirt may be picked up with the silage when conditions are wet and it is muddy around the silage pile or tube.

There will always be some soil contamination of grass and legume hay or silage. However, appropriate harvesting and storage management can reduce the ash content of the hay or silage.

We should all try to be 1 or 2 percent below the averages in Table 2. Anyone with 10 percent or less ash has done a good job of minimizing ash content of hay or silage. FG