There are a variety of different ways to orient a robotic milking stall within a pen, and it can be difficult to decide which orientation is best. When deciding which layout to choose, it is important to consider cow traffic choice (guided, semi-guided or free), cow sorting options when exiting the robot, footbath operation, secondary group access to the robot and future expansion plans.

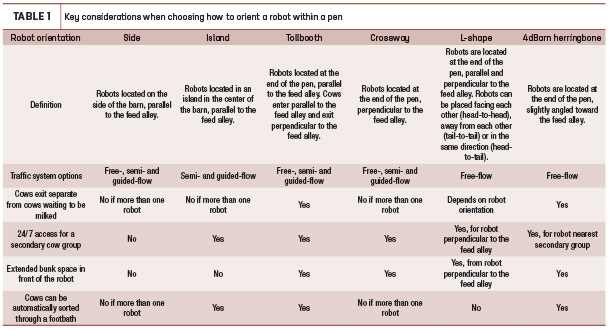

The six robot layouts we have commonly seen in practice include: side, island, tollbooth, crossway, L-shape, and 4dBarn herringbone. Each layout has its pros and cons, with the essential common goal of facilitating cow access to the robot to promote milk production and labor efficiency.

The ideal robot placement optimizes visits to the robot by reducing traffic around the robot and providing plenty of space to minimize congestion. Design should be used to promote robot visits, not feeding. Cows should exit the robot away from cows waiting to be milked to avoid congestion and competition, and there should be a protected entrance in front of the robot so that subordinate cows waiting to be milked cannot be easily displaced. This protected entrance should be about 4 feet long so that a dominant cow cannot push a waiting cow back by pressing against her shoulder.

Some robot layouts are better suited for guided-flow traffic systems with a commitment pen, while other layouts can only be used with free-flow traffic and allow for the placement of a fetch pen next to the entrance of the robot. Fetch pens should have a split entrance for cows to access the robot from either the fetch pen or the main milking group and should be sized to provide 20 to 30 square feet per cow for four to six cows.

Labor is also affected by robot orientation. We want to minimize the amount of time spent fetching and moving cows and minimize alley area around the robot that needs to be manually manure scraped. When there are multiple robots per pen, it is best to locate them in the same area so workers do not have to cross multiple points of cow traffic and repeat chores in multiple areas. At least one of the robots should provide 24/7 access to a secondary group of cows (usually a fresh-cow group), so cows do not have to be manually fetched two to three times per day, and they should be automatically sorted back into the pen, without the need for the presence of the farmer.

Regular footbathing is an essential lameness-management tool for conventional and automated milking system (AMS) herds for the control of infectious hoof disease. However, the location of the footbath in an AMS herd is challenging. Use of footbaths located in crossovers at the end of the pen, requiring the farmer to manually route the cows through the footbath, is inefficient and difficult to do, leading to infrequent use. Choosing a robot layout that automatically directs cows through a footbath after milking ensures frequent use of the footbath and minimizes labor and is preferred.

The table below explores key considerations when choosing how to orient a robot within a pen. Since each layout has its own set of pros and cons, it is important to choose the layout that best aligns with an individual farm’s management strategy and priorities.