Forages are the backbone of dairy rations on most farms. Forages impact dry matter intake (undigested neutral detergent fiber or uNDF), rate of passage (particle size), rumen environment (stable rumen pH) and economic feed programs (reducing the need for purchased grain and protein supplements).

Unfortunately, on some farms, the amount of forage available is deficient due to drought, rain damage of hay crop, early frost, winterkill and/or herd expansion. Forage extenders are alternative feed ingredients that can be used to supplement existing forage inventories on the farm to optimize production.

Know your forage situation

You need to assess your current inventory on your farm by forage types (tons of hay, haylage and corn silages, for example). Next, determine how you will allocate each forage type by class of dairy cattle on your farm. A forage allocation example is illustrated below.

- High-producing group/cows: 66% as BMR corn silage and 34% legume haylage

- Low-producing group/cows: 50% corn silage and 50% triticale silage

- Dry cows: 50% chopped straw and 50% corn silage

- Older heifers (over 12 months old): 65% triticale and 35% corn silage

- Young heifers (under 12 months old): 50% legume haylage and 50% baled grass hay

You can determine the number of animals in each class of dairy animals multiplied by the number of days times the pounds of forage dry matter that will be needed before the next forage harvest window. Calculate if you have adequate inventory available on the farm. The key is to know now if you will be short of any given forage (such as corn silage) and your strategies to shift the forage feeding program.

For example, if you are short of legume haylage, will you increase the amount of triticale to stretch the inventory, purchase hay to replace needed dry matter and/or adjust animal inventory (sell excess heifers could be considered)? Will you have small-grain silage available in spring to supplement your forage inventory? If you are going to be short, you will need to consider a forage extender. The important decision is to know this answer now to stretch available inventory and determine strategies on how to address this situation.

Forage extender choices

Dairy farmers have choices on forage extenders. Choice 1 is to consider NDF sources that contain similar or higher levels of NDF forage-digestible fiber (byproduct feeds). Choice 2 is to use a lower-quality forage extender to lower-nutrient-required animals (dry cows, low-producing cows and older heifers). This strategy can be used to control and limit dry matter intake (DMI). Choice 3 is to purchase local sources of hay, corn silage, legume silage or small-grain silage. Transportation cost, forage quality and forage consistency (level of dry matter, starch levels in corn silage, NDF digestibility and protein content of legumes are examples). A fourth choice is a source of physically effective forage needed in the feeding program to maintain rumen pH, cud chewing, rate of feed passage and animal health. This choice could depend on grain levels and high-quality forages available on the farm.

Selecting high-quality extenders

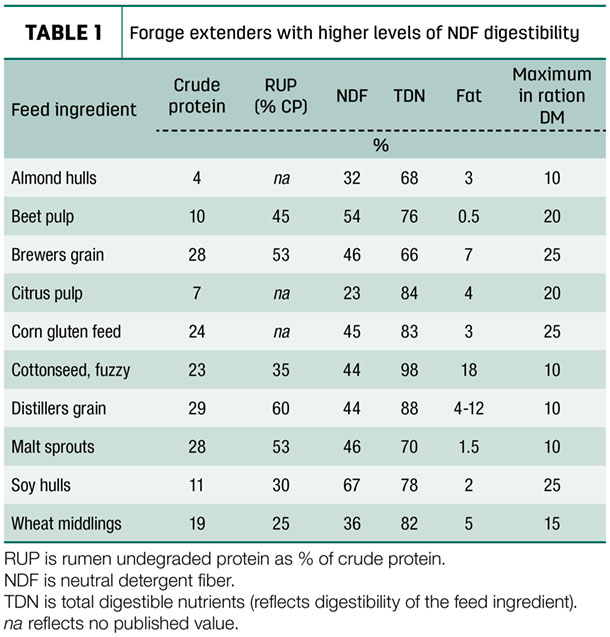

This approach focuses on substituting byproduct feeds higher in NDF digestibility. Table 1 lists several of these ingredients (depending on where you live and availability).

Total digestible nutrients (TDN) reflects quality of the NDF in the feed ingredients. The cost of each byproduct feed needs to be evaluated compared to other choices (Table 3), the level of nutrients being delivered in the byproduct feed and the dairy animal nutrient needed and provided by the byproduct.

Another consideration is using wet byproduct feeds such as wet gluten feed, wet brewers grain and/or wet distillers grain that can replace wet silages and can be palatable. With wet byproducts, calculate the cost per pound of dry matter, transportation costs (typically farms within 100 miles of the production facility can be considered) and storage time to avoid deterioration of the wet feed on the farm.

Storage and handling of wet byproduct feeds on the farm is another factor. Some dairy farmers may decide to purchase specific byproducts from their local feed supplier, have the company blend the selected dry byproduct feeds with protein and pre-mixes, and delivered to the farm. Advantages of using your local feed supplier are: Inventory control is not on the farm, cost of owning large quantities of a byproduct feed, and the supplier is responsible for quality control.

Selecting low-quality forage extenders

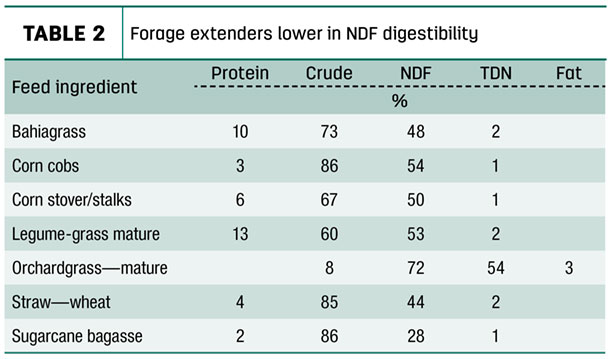

This approach can also be called forage filler feed ingredient. These byproduct ingredients can be used to limit feed intake when dairy cattle are fed free-choice. Table 2 lists several of these products.

An example on levels of lower-quality forage extender to feed dairy groups is listed below.

- High-producing cows: 0.5 to 2 pounds of dry matter per day

- Low-producing cows: 5% to 20% of the total ration dry matter

- Dry cows: 25% to 40% of the total ration dry matter

- Older heifers: 15% to 25% of the total ration dry matter

The levels of filler forages will depend on other forage ingredients, nutrient requirements and grain levels. For example, if corn silage is the main forage, higher levels of filler forage can be considered. These forages can also provide functional fiber depending on the processing of these forages. Due to lower palatability and risk of sorting, these forages need to be processed/chopped to under 1 inch theoretical length of chop (optimal length may be one-half inch). Adding water to the ration can improve filler feed intake (forage not as sharp in the mouth and more pliable) and reduce sorting.

Purchasing local forage sources

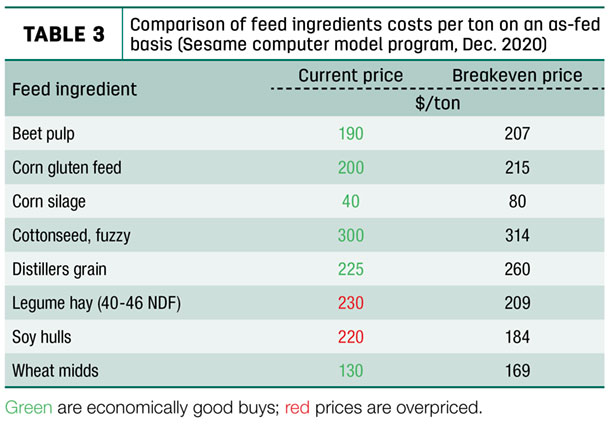

This step may be the easiest choice if available. Table 3 compared the relative cost to other feed ingredients using Sesame computer software from Ohio State University. Feed prices reflect Midwest feed ingredient costs in December 2020. Forage quality changes must be monitored to be sure you are getting the nutrient you purchased. Nutrient and dry matter adjustments should be determined if forage tests reflect an increase or decrease has occurred between seller and buyer. This change could be dry matter content, NDF digestibility, protein or starch levels, for example. Wet silages can be more difficult due to cost of moving water and stability of the silage after exposure to air.

Take-home messages

- Determine your current forage status and future needs.

- Adjust current forage levels in rations now and stretch existing inventory.

- Consider adjusting your dairy cattle inventory to feed.

- Position forage extenders based on NDF digestibility, costs, physical form and complementation to the existing ration.