The goal of precision nutrition is to formulate rations that support the nutritional needs of the herd and the financial needs of the business as closely as possible.

As our industry experiences unprecedented volatility, the more precise and efficient operations will be better positioned for long-term success.

Do you maximize today’s technologies?

A recent industry survey found that only 62% of the participants routinely use a dairy management software program, and 25% indicated they were considering purchasing feed management software in the year ahead. If you want to build a precision nutrition program, consider feed management software as the starting point. If you don’t have a program yet, talk to your nutritionist about the best option for your dairy, and then set goals together for utilizing the software to help achieve measurable improvements within the herd.

Obtaining technology is just step one; how effectively you utilize it is another. If you think you are ahead of the game because you have feed management software, think about what you are doing with it. Is it being used to its full value, or are you simply using it for electronic batch sheets and loading the feed into the mixer? If you want to better understand all the system can do, ask the software manufacturer to refer another dairy for you to talk to. Some of the most sophisticated operations have constructed feed centers and mills on the farm to maximize their use of the technology.

Whether or not you are intending to build your own feed center, having this management software will help you establish more accurate dry matter intakes, a key to ration formulation, and track ingredient usage and deviations from targets to help you fine-tune the ration and deliver your cows a more consistent nutrient package.

Furthermore, when using feed pricing capabilities, feed management software programs enable you to track your herd’s key performance indicators (KPIs) such as income over feed costs (IOFC), component efficiency and other feed conversion factors highly correlated to profitability. Coupling on-farm feed management software with a ration formulation system that utilizes nutrient analysis of your operation’s ingredient inventories, like Cargill’s MAX system, can bring another level of precision to ration formulation for your farm. The industry has the technology, so utilizing it in the most profitable way is crucial.

Do you buy ingredients or nutrients?

Delivering the consistency cows crave can be difficult when there is steady variation in commodities used to feed the herd, unless you are using precision nutrition to focus on consistency at the nutrient level. How frequently are you analyzing the dry matter of your forages and adjusting the feed recipe? Do you apply that same rigor to your commodity purchases?

Many of the staple ingredients, such as soybean meal and canola meal, have nutrient values that can vary considerably between different suppliers and load to load. Just like the quality and nutrient content of crops can vary from field to field, grain processing facilities extract nutrients from raw ingredients with different efficiencies, impacting the final nutrient composition of the byproduct meal. This doesn’t mean some facilities are better than others but rather that dairy producers have an opportunity to more precisely understand the nutrients entering their farm and therefore provide better nutrient consistency in their rations.

Once you shift your perspective to buying nutrients, not ingredients, you can make smarter commodity purchases. For instance, if you are evaluating three canola sources simply by the price per ton, and not factoring in the nutrient value, you might pick the cheapest supplier. However, if you knew the nutrient value of all three, you might see that the cheapest supplier had the lowest nutrient density, and therefore to meet the nutrient requirements of the cows, you would have to feed that canola option at a higher rate, and that ends up making the “cheap” feed more expensive in the long run.

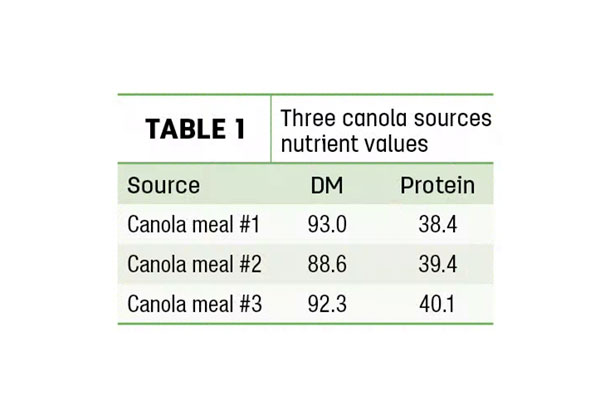

Sampling fast-moving ingredients might not seem valuable if the feed is gone before the results return; however, it can be a powerful tool over time. For example, the results will help nutritionists predict what nutrients will arrive in future loads (Table 1).

Establishing that one supplier provides 40% protein canola while another provides 38.5% protein starts to add up financially. That differential in crude protein (or perhaps fiber from fibrous byproduct ingredients) can have an impact on the cow, over time, especially when the nutrient specs do not match the “book values” used to formulate the diet. The net result is a diet on paper that does not match the diet your cows consume.

Variances in nutrients delivered could produce a difference of six to seven cents per cow per day in some cases. In other words, the nutrient value of the canola meal that two suppliers offer may differ by a few to $20 per ton.

Advancements in feed testing and data analytics have upended long-held nutritional wisdom in how to identify ingredients, how to characterize their nutrient profile and how to establish their value in a specific diet. Precision nutrition is the outcome of these advancements and has the ability to balance diets at the nutrient level, from continual ingredient sampling and nutrient analysis, not outdated book values from testing done many years ago.

Do you align production to pricing?

Aligning what goes into your production to cater to what the customer wants is a pretty basic principle of business. For a dairy operation, this means aligning the herd’s milk production with component pricing to more precisely produce a milk profile that pays. For instance, if the average price per pound of milk fat is $1.35, and that price is anticipated to increase to $1.75 per pound, there would be an economic benefit to increase the fat profile of the milk by adjusting diet carbohydrate or fat sources.

Similarly, if a producer’s goal is to boost protein from 3.1% to 3.3%, he or she can feed higher levels of certain amino acids, such as bypass methionine. While this may mean an investment of approximately 15 cents per cow per day, the return could be 40 cents or more per cow, depending on values of milk protein in your market.

One of the best key indicators of the success of a precision nutrition program is analyzing your milk component efficiency. This number will tell you how efficiently your herd is converting the diet into protein and fat milk components and is highly related to income over feed costs (IOFC). If you don’t know how to calculate component efficiency, check out this free online tool that can help you calculate where you are and assess how good your number is.

While it is possible to increase cow milk yield by a couple of pounds today by implementing certain measures, imagine starting that level of focus when a calf begins its journey in the herd. Precision feeding of calves and heifers focused on rumen development has been shown to produce animals with roughly 10 pounds higher milk production in first lactation. There lies opportunity for even more poundage per cow in the future.

By assessing the precision of your nutrition program today and learning where you can capture greater efficiencies, you can set smarter goals with your nutritionist that will help keep your dairy competitive and sustainable for years to come. If you have questions on these key areas, or want an assessment of your level of precision, feel free to email me.