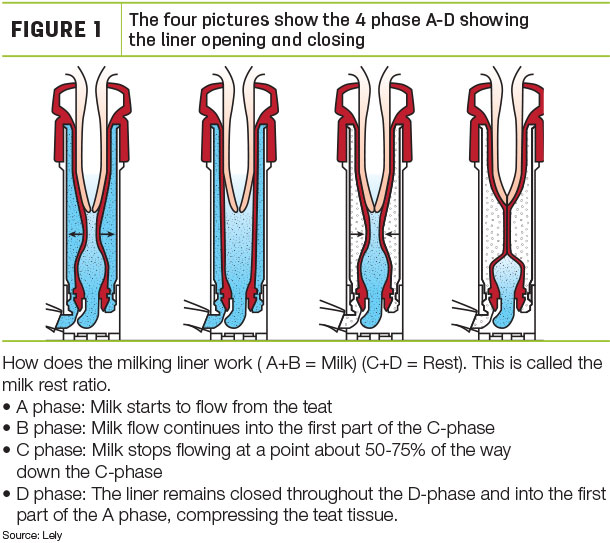

The function of liners is critical to the milking process. The liner opens and closes to interrupt the milk flow due to the pressure difference between the inside and outside of the liner (pulsation). Closure of the liner wall exerts pressure on the teat, which can be seen as massage. The massage ensures the backflow of fluids, such as blood and lymph, but can also be a burden on the teat and cause hyperkeratosis on the teat end (see Figure 1).

Within a herd, teat size can vary widely. That variety is even more apparent with multiple breeds in a herd or in the case of a group of only heifers. Therefore, considerations need to be made when grouping cows and sizing liners. If cows are grouped by lactation, a different liner may be best used in one pen versus others.

Teat scoring, as well as measuring teat length and thickness or diameter, are important considerations for liner selection. We recommend scoring at least 20 cows per robot on all quarters. This can be done quickly and easily with a teat-scoring tool. The data is then entered on a spreadsheet which tabulates averages for length and diameter to assess which liner is appropriate for the pen of animals evaluated.

If a liner change is recommended, performance measurements (teat-end health, somatic cell count, cow temperament, milk speed, etc.) should be closely monitored to evaluate the effectiveness of the new liner and to minimize any concerns resulting from the change. Choosing the correct liner is a matter of learning through strict monitoring. Your milking equipment provider can provide guidance in this area.

Considerations when selecting a teat liner:

- Vacuum level

- Teat length

- Teat shape

- Long/deep mouthpiece depth: good for slip reduction but problematic for short teats

- Short/shallow mouthpiece depth: good for short teats, slightly less slip reduction

- Tapered bore: good for accommodation of varied teat size but less desirable for extremely short teats

- Straight/cylindrical bore: standard design, consistent compression, less accepting of variability

- Rings/reinforcement on mouthpiece of liner: added stability or integrity (reduce chance of a tear)

- No rings/reinforcement on mouthpiece of liner: Reduced stability, improved flexibility, accommodate more variance in teat diameter

Years of breeding in North America have moved cows toward shorter teats. Commonly, short or shallow mouthpiece depth seem to be best for accommodating these cows.

There are many liners available. So how do you choose the best liners for your herd?

Silicon teat liners have a long life with as high as 10,000 milkings between change intervals. They have very good adhesion ability with flexibility and consistent performance from installation to removal with proper cleaning and maintenance. Silicon meets strict requirements for regulation on food safety for dairy products and hygiene globally and can be used in all milk markets.

Rubber liners often cost less to install and are often familiar to dairy producers. They have a shorter use-life than silicon liners (1,500 to 2,500 milkings commonly) and have less consistency from install to removal than silicon liners.

Once liners have been selected, be sure to observe milkings for at least 30% of the herd. Look for physical problems such as rings at teat base or blue teats. Take time to observe cow behavior. Are they kicking or do they seem restless?

Dealers and support people can and should do a dynamic vacuum test (teat-end vacuum) on 30% of the herd or 20 cows per robot. This data can help determine if the fit of the liner is good and the system is in good operating condition, providing vacuum levels within the design parameters of the specific liner chosen.

Choosing a liner (and appropriate milk settings) is an exercise in balancing the goals of milking quickly and gently. For a well-considered choice, contact your robotic milking adviser for a liner evaluation. ![]()

Gaylen Guyer is the aftermarket field specialist with Lely North America.