Consider this: 85% of farmers are applying some sort of forage preservative either at harvest or in the total mixed ration (TMR) wagon. Using an inoculant at harvest along with harvesting and ensiling practices can constitute a proactive approach. Still, time and heat brought on by the summer months can contribute to yeast and mold growth; aerobic stabilizers may be necessary to reduce heating and nutrient loss.

With hotter weather comes lower feed intake, lower milk yield and lower component production. A cow will already eat less when she is hot, and putting hot feed in front of her will only reduce her appetite more. While we can’t control the weather, we do have control over preserving our feed’s nutrient value, reducing dry matter loss and maintaining palatability.

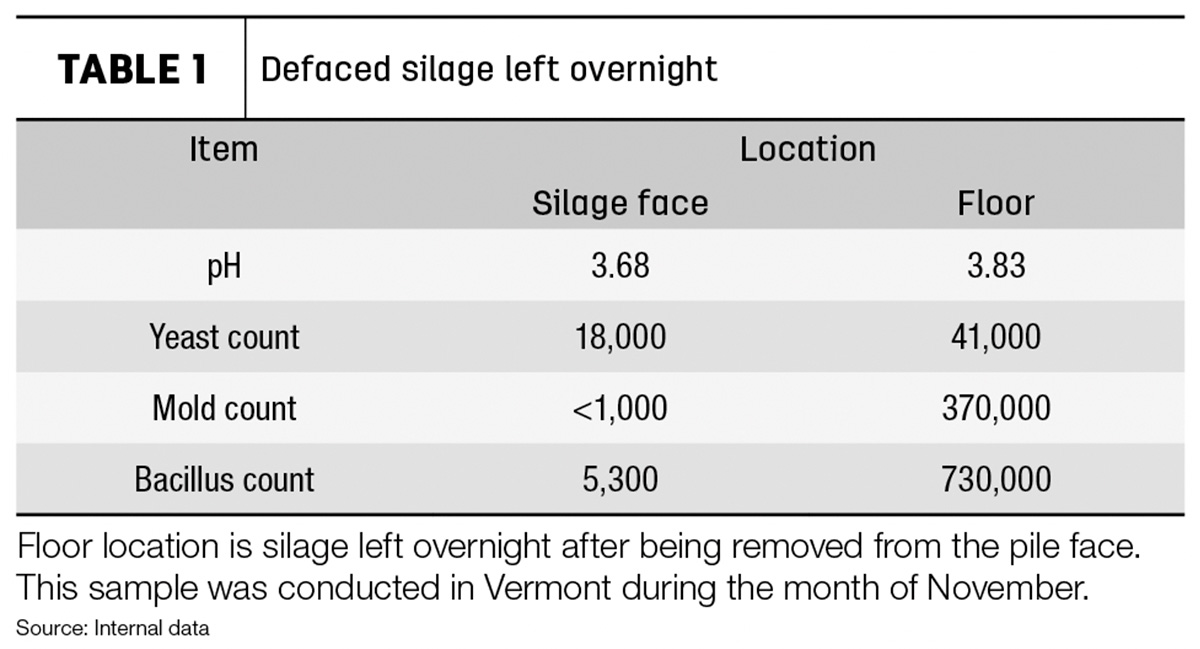

When silage is exposed to air – either after opening a bag, bunker or silo, or during feedout – fermentation acids (lactic, acetic, propionic, butyric) exposed to air are oxidized by yeasts and molds. The more silage is exposed to air, the more yeasts and molds flourish and degrade nutrients, produce heat and give feeds an off flavor. For reference, a feed sample with a yeast count greater than 100,000 and a mold count greater than 10,000 signals a reason for concern and action.

Corn silage preservatives: When and how to use

L. buchneri inoculant at harvest

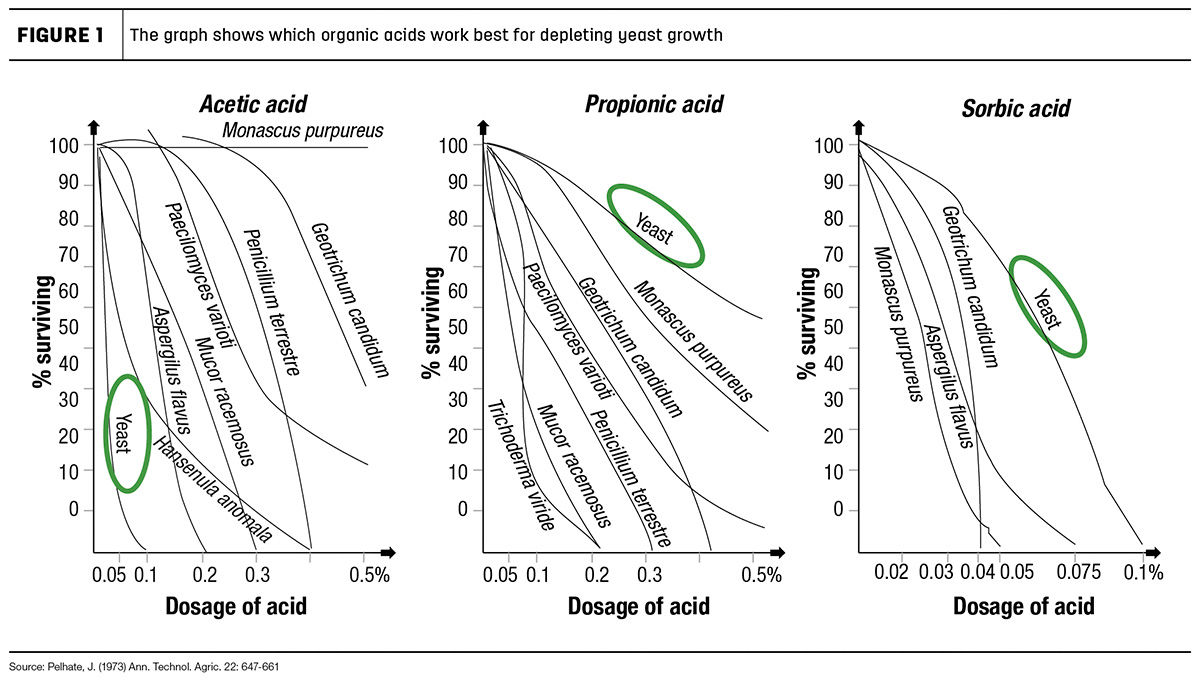

The strain Lactobacillus buchneri (L. buchneri) has been around for quite some time. Even though it has become a buzzword in the industry, a wide variety of products are available with this strain and are specifically used for aerobic stability. Feed that is aerobically stable is less likely to heat and spoil after feedout. The L. buchneri strain specifically produces acetic acid. Although we may typically think to use a lactic acid-producing strain, acetic acid is more efficient at eliminating yeast spores. Yeast is most commonly the culprit for hot silage, and acetic acid is one of the best acids for preventing yeast growth (see Figure 1).

Checking stability

Whether or not you use an inoculant at harvest, it is advisable to check silage stability by taking a feed sample between 30 and 60 days after ensiling. The fermentation section on your analysis will paint a picture of your silage stability based on its pH and acid profile.

-

pH: The final pH of corn silage at feedout should be below 4. Corn silage pH begins to fall relatively soon after packing and sealing, and the conversion of forage to silage begins once silage becomes anaerobic (without oxygen). To achieve successful fermentation, and prevent bad fermentation, the pH must be rapidly reduced. Forage inoculants can help ensure silage hits the correct pH and acid profile targets to promote stability, retain dry matter percentage and maximize nutrient preservation.

- Acid profile: A feed analysis will show you lactic acid and acetic acid concentrations. A target ratio for lactic to acetic is 3-to-1, and this indicates that proper fermentation has occurred. Using an L. buchneri inoculant at harvest, you can expect a higher acetic acid concentration, which may improve aerobic stability upon feedout.

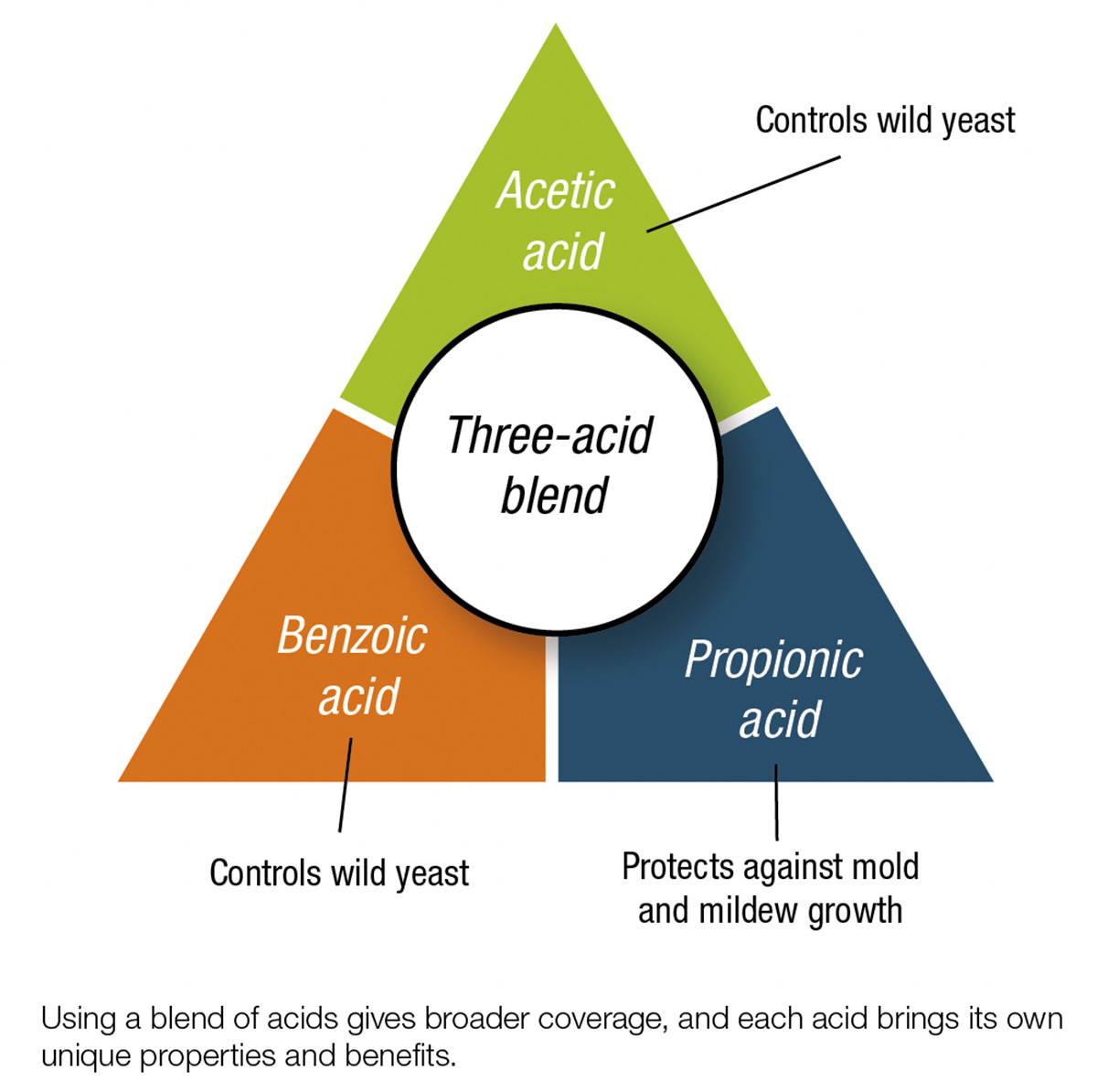

TMR stabilizer at feedout: If fresh feed already has yeast or mold in it, then it will deteriorate more quickly when exposed to oxygen and warm temperatures. TMR stabilizers are considered feed additives and are added as an ingredient to the mixer wagon to extend the bunk life of fresh feed. Few TMR stabilizers use a blend of organic acids for inhibiting both yeast and mold. A three-blend acid TMR stabilizer may include acetic, benzoic and propionic. The acetic and benzoic acids control wild yeast while the propionic acid protects against mold growth.

There are multiple benefits to using a TMR stabilizer, especially if you know your feed holds mold or has high yeast counts. It can reduce nutrient loss due to yeast and mold growth, and improved feed palatability helps prevent reduced dry matter intake.

Identifying forage issues

These are some practical observations you can make of your own forage and feed management practices. Identify forage issues by recording them below and marking “Y” for yes and “N” for no.

Y or N: Are you taking less than 6 inches off the face of the bunk?

Y or N: Are you leaving a defaced silage pile overnight? (See Table 1)

Y or N: Is your forage heating 5-10 degrees above the ambient temperature it was put up at?

Y or N: Do you have visible mold?

Y or N: Is there an alcohol odor coming from your forage?

Y or N: Is your silage looking off color?

Y or N: Based on fermentation feed sample analysis, is the pH high?

Y or N: Based on fermentation feed sample analysis, are acid detergent insoluble crude protein (ADICP) numbers high?

Y or N: Based on fermentation feed sample analysis, is butyric acid high?

If you can answer yes to any of the above questions, you may want to consider applying a TMR stabilizer that has a blend of organic acids. A yes also may be a sign for your team to evaluate harvesting, packing and ensiling procedures for next year. Think about it this way; would you rather eat a fresh salad or a plate of hot leftover casserole in the summer? Just know your cows feel the same way.