With interest rates, inflation and input costs on the rise and milk futures trending in the opposite direction, a lot of dairy producers I talk to are asking me this question: Is it possible to be a profitable dairy farming business, despite these external pressures?

My answer: Absolutely.

The secret to ending 2023 with cash in hand isn’t just a matter of risk management. Rather, it’s taking a good, hard look at the costs you can control and taking actions to reduce expenses.

Here is how to do it.

Labor

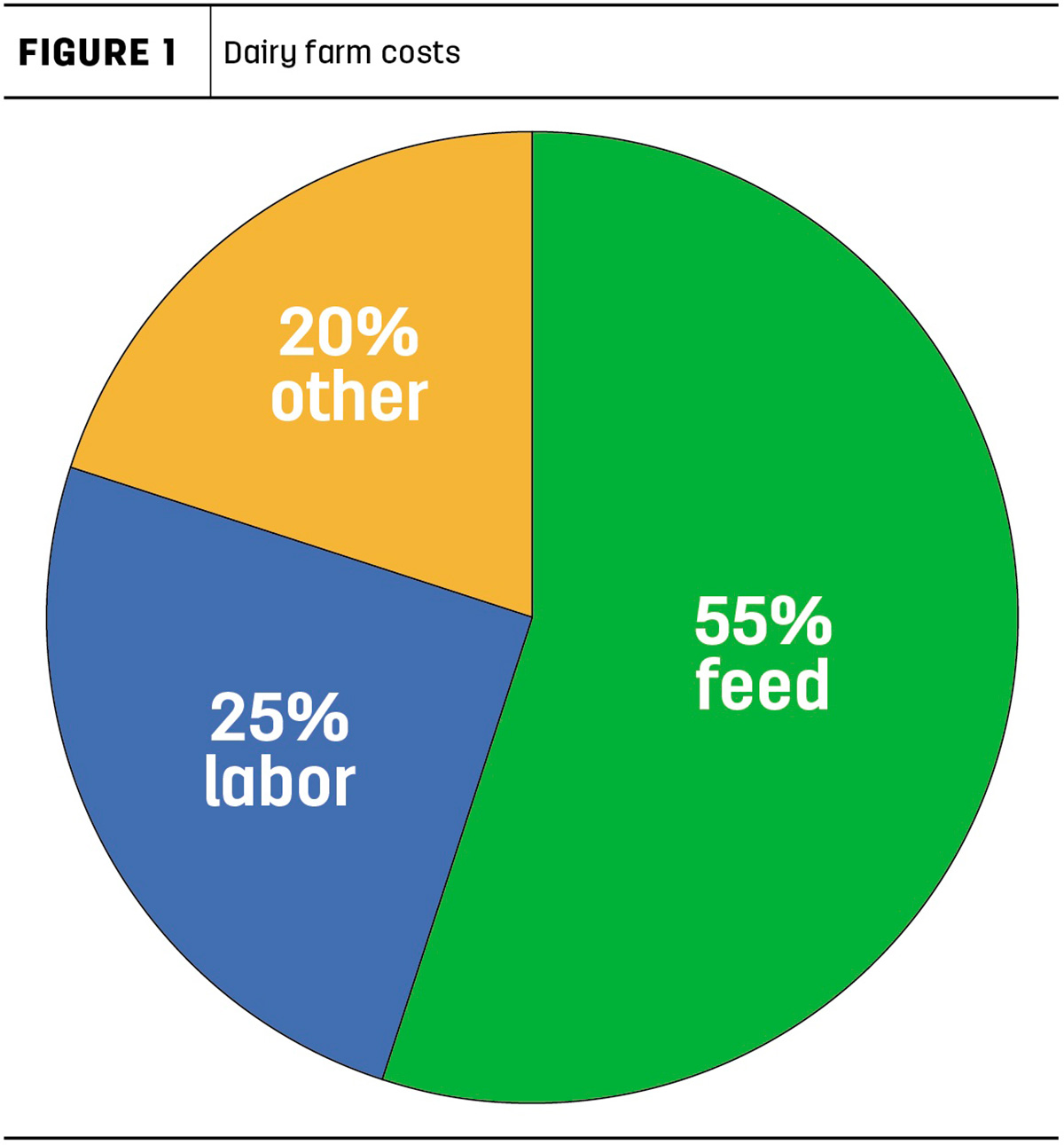

For most dairy clients I work with, a quarter of their expenses are in wages and benefits for employees. However, this is also the area where cost savings can be realized quickly by making a few tweaks to routines that can save time and manpower. The lowest-hanging fruit is most often found in the milking parlor. On a recent farm visit, an audit of the milking routine and cow flow in and out of the parlor presented an opportunity to streamline steps and tighten up efficiencies. The result: That parlor is now humming at seven turns per hour with the exact same number of employees. That means more milk per employee.

Outside of the parlor, there are other places to look next to streamline tasks that can shave hours off the daily workload and perhaps even a full-time employee position. Take a visit to the fresh pen. How long are cows locked up? Are your protocols for monitoring these cows overly labor-intensive? Which employees can be cross-trained to handle multiple areas? A simple audit followed by re-organization of the labor force may show you that you are actually overstaffed.

When it comes to labor, the cost of turnover is an additional expense that manifests in multiple ways. That is why dairies in competitive labor markets are upping their game to retain good people. Not only must employees be paid a fair wage, but they also seek a good work culture, conditions and job satisfaction. If you can create an environment where employees have the tools they need to get their jobs done, confidence in their safety and an atmosphere where they want to come to work every day, you’ve just saved yourself money and stress.

Feed costs

More than half of the dollars paid out by any given dairy are directly related to the cost of feed. One way to control this is by increasing the portion of homegrown forage in the diet. I’m seeing dairies successfully bump up from 40% to 55% of forage in the ration to 60%. This provides an additional opportunity to optimize forage quality by maintaining tighter control over the harvesting and storage process. Thus, potential cost savings can be captured with less needs for additives that Band-Aid sub-par forages.

In addition to additives, take the time to evaluate all ingredients in the diet. There may be some that are no longer needed. Shop around to other suppliers, and you may be surprised at what you can save by making a couple of phone calls.

Another way to shave off feed costs is to organize pens by stage of lactation, so that the highest-energy feed is going in front of the highest-producing groups and vice versa.

Other expenses

While feed and labor make up the bulk of expenses, the last piece of the pie catches all the smaller line items that add up. Now is the time to walk through each line, evaluate the protocols and determine whether or not it’s still necessary. Two key areas where I see untapped cost savings: milking parlor dips and chemicals, and preventative cow health interventions. Good management can often replace blanket treatments and protocols.

While there are things we can’t control in the dairy business, what you can do is take the time to audit and evaluate labor, feed and other expenses and take the actions that will lead to a profitable year, despite the odds, in 2023.