The dairy industry is facing numerous challenges with a pressing need for sustainable practices that optimize resource utilization and improve profitability. One crucial aspect that directly influences the success of dairy production is feed efficiency. Efficient feed utilization not only impacts the economic bottom line but also plays a significant role in environmental sustainability. As the global demand for dairy products continues to rise, the industry must find innovative ways to produce more with fewer resources.

Residual feed intake as an alternative measure

Amid the pursuit of optimal feed efficiency, the emergence of residual feed intake (RFI) has proven to be a game-changer in the dairy industry. It provides an innovative and precise approach to assess feed efficiency by considering individual animal characteristics. It calculates the difference between an animal's actual feed intake and its expected intake based on factors like bodyweight and production.

Residual feed efficiency essentially measures the efficiency with which an animal utilizes feed for both maintenance and production purposes. A negative RFI indicates that the animal consumes less feed than expected, demonstrating superior feed conversion efficiency. On the other hand, a positive RFI suggests higher-than-expected feed intake, indicating that the animal is less efficient in converting feed into production.

Identifying cows with lower RFI values becomes a powerful tool for optimizing herd efficiency. By incorporating RFI data into breeding and management decisions, dairy producers can work toward enhancing the overall productivity and sustainability of their operations. Moreover, improved feed efficiency translates into enhanced profitability and optimized resource utilization, which are critical factors for long-term success in the dairy industry.

Let's consider for example two cows, A and B:

Cow A produces 80 pounds of milk and consumes 55 pounds of dry matter.

Feed efficiency of cow A: Milk production (80 pounds) / DMI (55 pounds) = 1.45

Cow B produces 75 pounds of milk and consumes 50 pounds of dry matter.

Feed efficiency of cow B: Milk production (75 pounds) / DMI (50 pounds) = 1.50

Based on this efficiency we would select cow B over cow A for our breeding programs since it shows slightly higher efficiency. What would happen if we used RFI instead in the calculation of feed efficiency?

Cow A adjusted feed intake: 52 pounds (55 - 3) and produced 80 pounds of milk.

Feed efficiency with RFI adjustment for cow A: Milk production / Adjusted feed intake = 80 pounds / 52 pounds ≈ 1.54 (rounded to 2 decimal places)

Cow B adjusted feed intake: 52 pounds (50 + 2) and produced 75 pounds of milk.

Feed efficiency with RFI adjustment for cow B: Milk production / Adjusted feed intake = 75 pounds / 52 pounds ≈ 1.44 (rounded to 2 decimal places)

Based on the calculations with residual feed efficiency, cow A now shows a higher efficiency (1.54) compared to cow B (1.44). This emphasizes the significance of managing feed intake based on individual cow characteristics to optimize milk production and resource utilization.

Measuring individual feed intake in commercial dairies, however, presents several challenges, but finding practical solutions is essential for optimizing feed efficiency and overall herd performance. Large-scale operations often involve a significant number of cows, making direct and continuous monitoring of feed intake cumbersome and expensive. However, advancements in technology offer promising approaches to overcome these difficulties. Automated feeders equipped with electronic identification systems can track individual cow intake over time, providing valuable data for feed efficiency analysis. Additionally, implementing regular body condition scoring using 3D cameras and using electronic milk meters can aid in assessing individual cow performance. To improve accuracy, it is crucial to integrate data from multiple sources, such as milk production records and regular animal weight measurements, with the use of data analytics and machine learning algorithms.

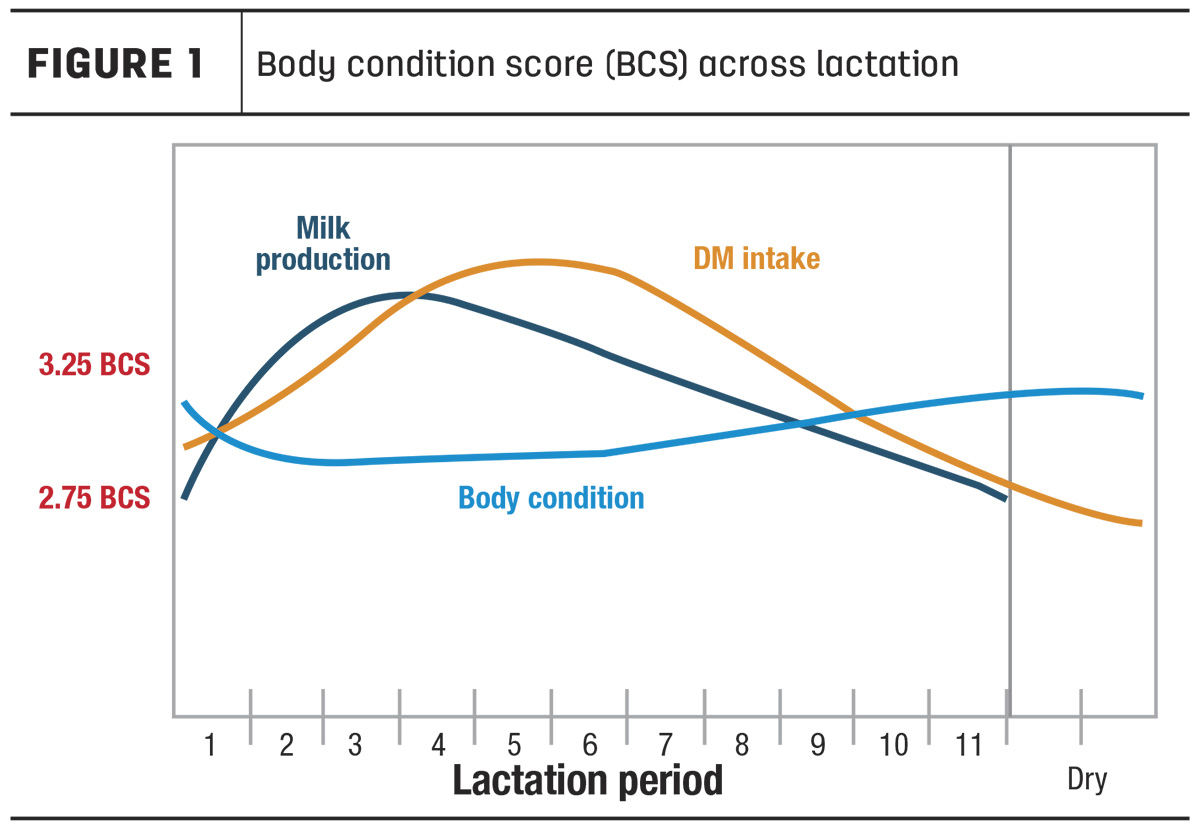

To accurately measure feed efficiency, it is essential to consider weight changes during lactation, particularly early bodyweight loss due to fat mobilization (Figure 1). Not measuring these changes leads to inflated feed efficiency estimates.

For more precise results, it is recommended to measure intake and production during the second month of lactation when bodyweight stabilizes. Studies have explored the use of 3D camera technologies, incorporating variables like bodyweight, height and body depth, to assess body condition score (BCS) and dairy type traits. These models achieved high accuracy in predicting bodyweight with a coefficient R2 of more than 0.90. Feed efficiency is influenced by various factors beyond milk components, including genetics, diet, management practices and environmental conditions.

Raw milk production, however, does not account for variations in milkfat or milk energy content. This makes it an incomplete measure for comparing feed efficiency between farms. By using fat-corrected milk, milk production is standardized to a common fat percentage allowing for a fair comparison between cows or herds. This is particularly important when evaluating feed efficiency because it considers the energy content of the milk produced relative to the feed consumed.

Let's use again the example of farms A and B with milkfat percentages of 3.5% and 4.2%, respectively. We will first calculate the 4% fat-corrected milk (FCM) for each.

Farm A produces 80 pounds of milk per cow with a fat percentage of 3.5%.

Cow B produces 75 pounds of milk per cow with a fat percentage of 4.2%.

To calculate the 4% FCM for each, we need to adjust the milk production based on the fat correction factor:

Fat correction factor for farm A: 3.5% (actual fat percentage) / 4% (desired milk fat) = 0.875

4% FCM for farm A: 80 pounds x 0.875 = 70 pounds

Fat correction factor for farm B: 4.2% (actual fat percentage) / 4% (desired milk fat) = 1.05

4% FCM for farm B: 75 pounds x 1.05 = 78.75 pounds

With the 4% FCM equivalent for each farm, we can now calculate their feed efficiency by dividing it by their average dry matter intake per cow:

Feed efficiency of farm A: 4% FCM (70 pounds) / DMI (55 pounds) = 1.27.

Feed efficiency of farm B: 4% FCM (78.75 pounds) / DMI (50 pounds) = 1.58.

Farm A now shows a feed efficiency of 1.27, while farm B has 1.58. In this case, farm B has a higher feed efficiency, indicating that it produces 1.58 pounds of 4% FCM per cow for every pound of feed consumed compared to the 1.27 of farm A. By using 4% FCM, we account for the differences in milkfat content between farms and can make a fairer comparison of their feed efficiency.

Residual feed intake (RFI) provides a powerful tool for evaluating feed efficiency in dairy production. By accurately measuring individual feed intake and implementing RFI, dairy producers can make informed decisions to enhance overall herd efficiency and profitability. It is vital to consider weight changes during lactation, and the use of 3D cameras offers a promising solution to overcome the challenges of monitoring individual feed intake accurately. Frequent body condition scoring and weight assessments, along with 3D camera technologies, play a pivotal role in optimizing feed efficiency and ensuring a sustainable future for the dairy industry.