Livestock producers and nutritionists recognize that all feed ingredients have some amount of variability in nutrient content. A quick summary of commercial laboratory data supports this comment.

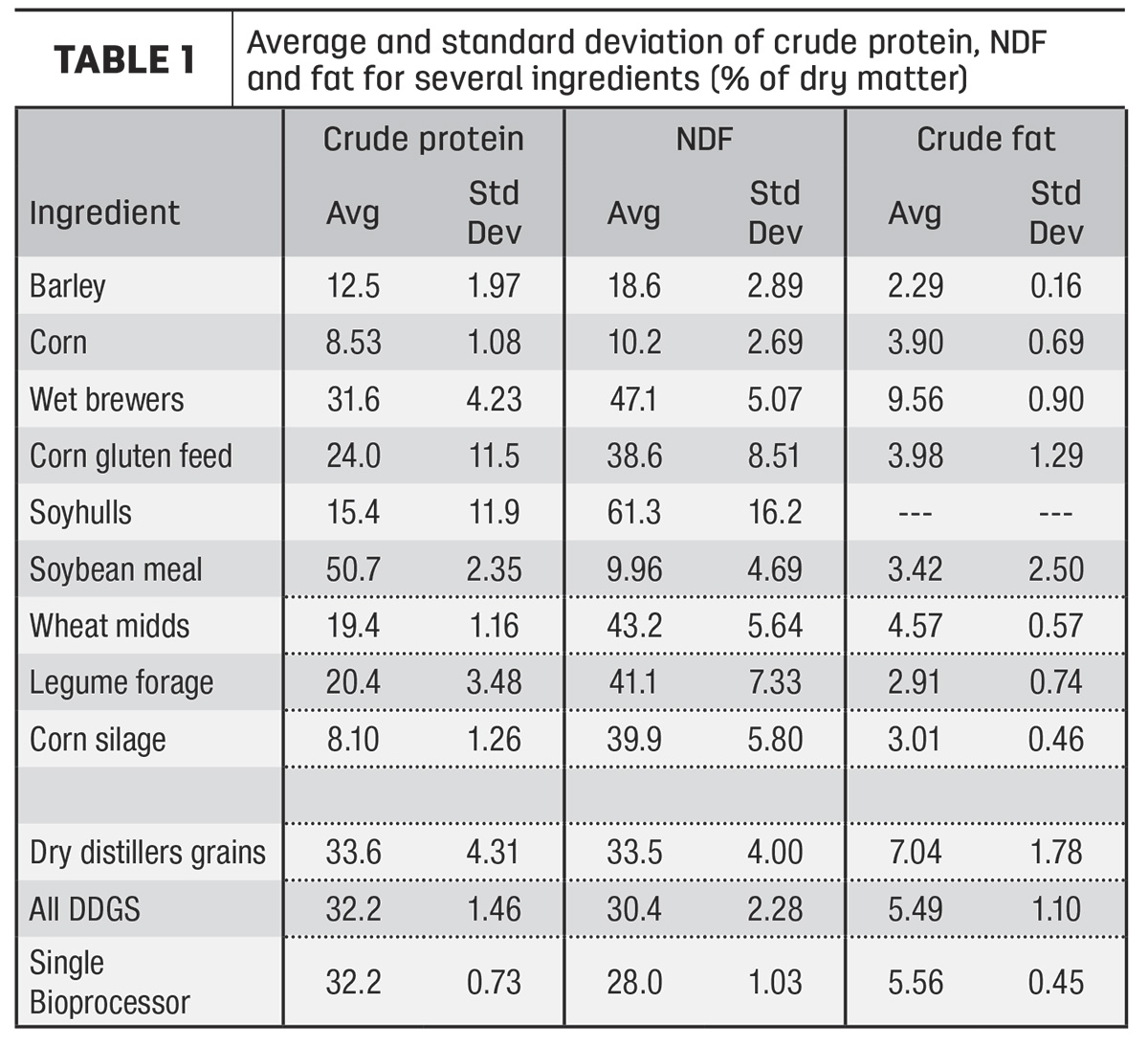

Table 1 shows the average and standard deviation of protein, neutral detergent fiber (NDF) and crude fat of several commonly used feedstuffs.

Criteria for the search included only samples collected from Midwest locations from Jan. 1, 2023, through Nov. 15, 2023.

Several of the ingredients we consider as “byproducts” or “coproducts” do have quite a bit of variability.

Wet brewers grains, corn gluten feed and soyhulls have elevated standard deviations for all nutrients. However, even ingredients like soybean meal, which we consider as very consistent, have variability.

Distillers grains variability

Table 1 also breaks apart the distillers grains samples. Many nutritionists view distillers grains as more variable than other commodities. A lot of this perception originates from the rapid growth of the distillers industry. Initially, bioethanol producers focused more on bioethanol production rather than distillers grains quality or consistency. However, as the industry matured, these producers recognized the value of distillers coproducts and have placed an emphasis on improving the nutritional value.

However, research has demonstrated that differences in bioethanol production processes affect the nutritional quality of the distillers coproducts. Distillers coproducts originating from bioprocessors with the same process have significantly less variability. Table 1 highlights these differences. The values for “Dry distillers grains” came from distillers grains from different bioethanol producers. Meanwhile, "All DDGS" samples came from bioprocessors using the same production process, and the "Single bioprocessor" includes samples from a single bioprocessor.

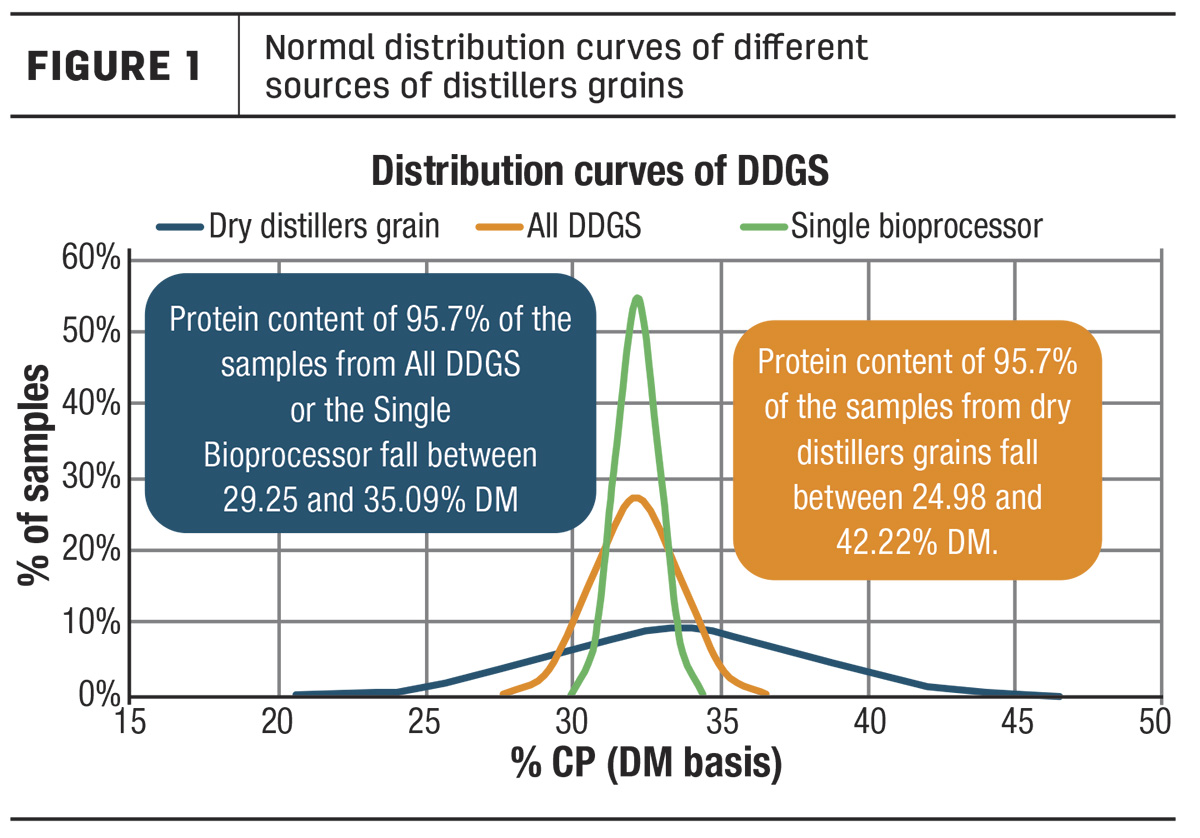

Figure 1 visually depicts this relationship for protein. Assuming a normal distribution, approximately 96% of the samples from a single bioethanol producer would fall between 29.25% and 35.09% dry matter, a range of 5.84 points. Meanwhile, 96% of the samples from all producers would fall between 24.98% and 42.22% dry matter – a difference of 17.24 points or almost three times that of a single producer.

Impact on formulation strategies

If a producer purchases dried distillers grains that has a mean crude protein concentration of 33.6% of dry matter and a standard deviation of 4.31, then 16% of the loads would have a crude protein value less than 29.3% and 16% of the loads would have a crude protein value greater than 37.9%. Expressed slightly differently, if a nutritionist formulated a diet to contain 10% distillers grains and they received a load of distillers grains that had 29.3% protein, it would reduce the total protein of the diet by almost half a percentage point.

The impact on animal performance would depend on many other factors. However, it could represent a significant impact on milk production, growth or feed efficiency. As a way to address these challenges, nutritionists can choose to include lesser amounts of more variable ingredients in their formulations. Unfortunately, this could result in more expensive formulations. Nutritionists may also choose to formulate using a reduced protein value for the ingredient. This ensures the protein content in the formulation meets the animal’s requirement. It also results in overfeeding protein which can cost more and increase nutrient waste.

Precision nutrition

This all relates to an important concept often referred to as precision nutrition (Figure 2). Precision nutrition (in addition to precision feeding) highlights the importance of matching the nutrients provided in the diet to the animal’s specific nutrient requirements.

As previously discussed, a lack of consistency in ingredients results in the need for over-formulating diets, which ends up increasing costs. Alternatively, not accounting for greater variability ingredients can probably reduce feed costs. However, animal performance will be affected because the nutrient content does not match the nutrient requirement of the animal.

In conclusion, livestock producers and nutritionists must manage around variability for all ingredients in their formulations. Even ingredients we typically consider as very consistent have a certain amount of variability that could affect animal performance. Fortunately, strategies like sourcing ingredients from a single producer can help minimize the negative effects on animal performance. All of this becomes extremely important when discussing concepts like precision nutrition and sustainability.