At first glance, the domestic dairyman will see the exporters as competition for hay, and this is true. However, the exporters have “raised the bar”, so to speak, on quality, and for the last several years higher-quality hay has been available for the domestic dairyman that won’t go to export than existed before.

We are now seeing five full cuttings in areas that once only grew three cuttings. This is a dramatic increase in quality, and also in tonnage.

Historically, first cutting was once cut late in June, with lots of bloom. Second cutting was taken generally after the grain was harvested, when it was convenient, and it was good and mature.

This is why second cutting still has somewhat of a bad reputation for quality and feed-ability.

The third cutting, then, was the premium soft, tender hay. With current practices, the first is taken pre-bloom, and given a bit of decent weather, it is often difficult to tell which is first cutting and which is second.

The third and fourth cuttings then become the candidates for “hard, brittle stem” summer cuttings, and fifth cutting, weather permitting, is now the “super-soft” cutting. With the reference to “weather permitting”, it’s obvious that growing hay is both a gamble and as much an art as a science.

The Pacific Rim buyers want hay that both looks nice and feeds nice. They are now asking for hays with a lab analysis showing at least 20 percent crude protein, no more than 30 percent acid detergent fiber (ADF) and no more than 40 percent neutral detergent fiber (NDF). This will produce a relative feed value (RFV) of above 160.

If the protein goes over 24 percent or the RFV goes over 180, most dairies have a problem making their ration work with it, because it has too much energy and protein, with too little fiber.

Certain areas of Japan have access to byproduct feeds that are high in both protein and nitrates, so the forages purchased from the Pacific Northwest need to fit with the rest of their feed program.

As for looks, leaf retention is king. Japanese buyers will shake a handful of hay to see how well the leaves stay attached to the stem.

To make this kind of hay, it needs to dry in the windrow and then be baled with just enough dew moisture to hold the leaves and stems attached to each other, like pressing a flower in a book.

The leaves should be whole and holding firm to the stem they grew on. If it was cut in time to be tender, and baled to preserve the leaves, then some top-of-windrow bleach will be accepted.

Some areas of Japan will accept first cutting that has had a light shower. But if it is baled too dry so the leaves are shattered and loose from the stems, then no other “pluses” will make it marketable to the Japanese.

Of course, too much moisture also won’t work. Small bales, either two-string or three-string, that have 18 percent or more moisture at baling run a risk of turning brown in the bale, or worse yet, molding. The other moisture pitfall to avoid is baling with too much stem moisture.

If the finished product shows up with stems that look shiny or slightly greasy, just a touch off-color toward brown, then it’s too much stem moisture. Too much stem moisture makes the stems brittle and bitter, affecting the cow’s appetite for that hay.

In the last few years, big bales have entered the export scene. The standard package for marketing big bales to Japan is a “sleeved” big bale.

To make these big bales, either 4x4s or 3x4s are pushed through a grid, best described as a giant French-fry slicer, with the grid squares being anywhere from 6 inches-by-6 inches up to 12 inches-by-12 inches.

The resulting product falls into a hopper which feeds a press chamber, where the mix is compressed and forced out of a rectangular opening.

At this point, a sleeve, made of the same woven plastic material generally found in grain bags, is placed over four sides of each unit as it comes out.

The sleeve contains the hay in a rectangular shape, which is just right to fit stacked three tall and two wide inside a standard export container.

The hay purchased for export for this purpose is best described as “clean and green.” The leaf retention for this product is of lesser importance than other hays purchased for export.

Some exporters are slicing the 3x4 bales into smaller sizes and packaging them in the same finished size as hay sourced from either two-tie or three-tie small bales.

To produce hay of the quality needed for this usually takes somewhat of a “learning curve” to get the proper leaf retention without the hay being too high in moisture.

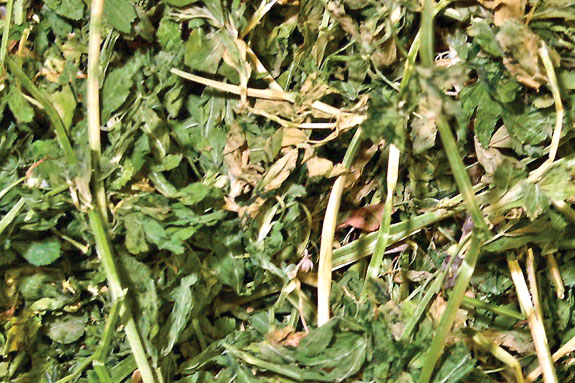

See the photos above, which compares leaf retention from two-tie and big bales. Baled correctly, there is not much difference.

The moisture at baling for the big bales should be 13 percent to 14 percent; considering that the stems are cured and dry and that the moisture at baling is dew moisture.

That’s right; to make high-test hay exportable, the big bales must be produced with some dew moisture.

The bales made in the heat of the day that leave the leaves in the field or shattered will never be top-quality hay, no matter how green or high-test it is.

Japan has plant quarantine standards that eliminate hays that contain certain things: wheat and barley, or straws from either (triticale is seen as wheat), quack grass in any form and dirt.

Live insects and rodents will also send a shipment back. If you use wheat or barley as a nurse crop as you establish a stand of alfalfa, you will usually not be able to sell it on the export market due to volunteer wheat or barley plants and straw. Haystacks covered with straw or bedded on straw are also not exportable.

The four general causes of dirt in hay are gopher mounds, circle-wheel tracks that bulge up into the haying equipment, rakes set too low and dirt from neighboring fields blowing in.

It’s not uncommon for a plant quarantine inspector in Japan to spread a clean white sheet on the floor, then break apart three or four bales of alfalfa from a container, then move the hay from the sheet, and if half a thimble-full of dust is left on the sheet, he may send back the whole shipment of hay.

This is why dirty bottom bales, even if they are dry, are not acceptable for export.

Other problems that make hay hard to export are infestation with dead stem from the previous year or previous cutting, and with cow pies.

The previous year’s dead stem and most cow pies can be taken care of by dragging the fields with a tire drag in the spring when the old plant matter is dry, and before the new crop has emerged. It’s all part of being a serious professional, a real hay grower and an artisan. FG

PHOTOS:

Baled correctly, there is not much difference in leaf retention between a 2-tie small bale (top) and a 3x4 big bale (bottom). Photos courtesy of Brad Nelson.

Q & A — Export hay

I made a long phone call into a short one a couple of weeks ago by referring a hay grower to the Jan. 1, 2011, issue of this publication and the article on making hay for the export market. Gary called me back and stated that I was right; the article answered a lot of his questions.

Then he asked, “What’s the difference between export hay and dairy hay?” Since he may not be the only one with that question, I’ll answer it here.

If export hay has the test that the dairyman wants, then it will work fine for dairy hay. Some grades of export hay, while attractive in appearance, will not have the proper test (crude protein of 20 to 22 or above, ADF (acid detergent fiber) of 30 or less and NDF (neutral detergent fiber) of 40 or less, which will give a RFV (relative feed value) of about 160) to produce the amount of milk the dairyman is expecting.

It’s notable that hay much over 180 RFV is usually not wanted in Japan because of the difficulty of feeding hay with such low fiber, even though some grade it as “supreme.”

One Idaho grower who also puts up hay on a custom basis for a large dairy stated that what the dairy really wanted was hay in the 160 to 180 RFV range; above that and there is too little fiber to work well in the rumen of the cows.

Export hay must be clean of certain weeds, grasses and grains to get into Japan. Volunteer wheat and barley, or the straw from either, will cause a shipment of hay to be returned from Japan.

Quackgrass and any grasses that are seen as “cousins” of wheat or barley are also prohibited in Japan. The volunteer grains are usually not a problem to a domestic dairy farmer.

Hay for export must be cured down to around 12 percent moisture for export. Much more moisture than that and it will sweat inside the container, then condense on the container’s ceiling and “rain” on the hay.

This results in a very disturbing scene when the container is opened, sometimes with the hay covered with mold. Higher-moisture hay, within reason, can be utilized by most dairies.

The same holds with hay cut young that takes a shower. If your neighbor watches how you put it up after the shower, it may still make nice dairy hay.

Hay with more than minor “top-of-windrow” bleach usually will not work for export. While the domestic dairyman will not like dirt in the hay (think gopher mounds or irrigation machine wheel tracks), it becomes a point of price negotiation, but for export, dirt is forbidden. FG