Baleage can have several advantages over dry hay but also poses some production challenges.

Keys for successful baleage production

The chances of successful baleage production can be increased by applying best management practices. Some management practices that will help ensure optimum quality baleage include:

1. Bale at proper moisture content

Proper moisture levels at baling ensure that fermentation will occur after the bale is wrapped, and oxygen is eliminated from the bale. Generally, the optimal moisture for baleage is between 45 and 60 percent, but can also be achieved at moisture levels slightly greater than or lesser than that range. Moisture levels greater than 60 to 65 percent can result in spoilage and low palatability of forages, and moisture levels less than 40 to 45 percent can result in mold growth.

If moisture levels are greater or lesser than optimal, it is essential that two more layers of polyethylene plastic film are used to wrap the bale as soon after baling as possible to eliminate oxygen and induce anaerobic fermentation as quickly as possible.

2. Mow at correct stage of forage maturity

As forages mature, the nutritive value of the forage declines. Low-quality forage for the class of livestock to be fed cannot be corrected through fermentation. It is essential to harvest baleage at the correct stage of maturity in accordance to the species and class of livestock that is to be fed. If the highest-quality feed is essential, earlier in the growth period would be ideal. However, if yield is a priority, harvesting later in the growth stages would be ideal.

Generally, as forages mature, crude protein (CP) concentrations and the percentage of total digestible nutrients (TDN) also declines. Dry mater (DM) accumulates as lignification and fiber components of the plant climb as forages grow and mature. Understanding the nutritional requirements of the class of livestock you are feeding in accordance with the nutrient composition of the forage at various stages of growth is the best way to know optimal time of harvest for baleage production.

3. Wrap the bale as soon after baling as possible

Ensuring the internal bale temperature does not exceed 120°F helps ensure the bale does not heat too high to damage available proteins. The elimination of oxygen from the bale as quickly as possible after baling is the best management practice to ensure the internal bale temperature is kept lower than 120°F. If temperatures exceed 120°F, the protein goes through a Maillard reaction, rendering a portion of the previously available protein as unavailable.

The correct number of plastic layers (wraps) is also paramount to keeping the bale temperature as low as possible and eliminating oxygen quickly to initiate the fermentation process by anaerobic bacteria. A minimum of six wraps (six layers of 1-millimeter plastic) should be applied to each bale, but eight wraps is preferred.

4. Make the densest bale possible

Experimental methods: A study evaluating the effects of bale density on baleage quality and bunk life was conducted at Pennsylvania State University’s Russell E. Larson Agricultural Research Center. This study evaluated four different balers set to bale at maximum density traveling at three different speeds: 4, 8 and 12 mph. Bales were wrapped within four hours after baling at a minimum of 6 millimeters of wrap on each bale, ensuring the elimination of oxygen and an internal temperature below 120°F.

Thermocouples were inserted into the bales four hours after wrapping to monitor internal temperature for the duration of the study. After 28 days, bales were unwrapped, and forage samples were collected from each bale to determine forage nutritive value. Bales were then allowed to sit in the external environment, and internal temperature was monitored until bales reached 2°F warmer than their baseline temperature at the time of unwrapping, at which point the bale was considered spoiled and unfit to feed.

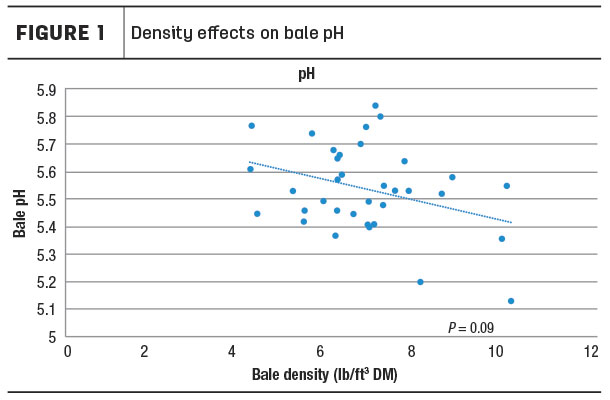

Discussion: Across all balers and speeds, results indicated bale density directly impacts baleage quality. The greater the bale density, the lower the pH and sugar content of the fermented bale. This indicates proper fermentation of the sugars available under anaerobic conditions.

As forages ferment, anaerobic bacteria convert sugars to acids as a byproduct of the fermentation process. A low pH is desired in any ensiled forage as this is an indicator of proper fermentation and stabilization of the forage for as long as oxygen is eliminated (Figure 1).

Total acid production, including lactic and acetic acids, were greater in bales with greater densities. Greater acid production is desired in ensiled forages because it ensures stabilization of the forages and indicates better forage quality and feeding value of the fermented forage. As bale density increased, lactic acid, acetic acid and total acid percentages increased.

Total acid production, including lactic and acetic acids, were greater in bales with greater densities. Greater acid production is desired in ensiled forages because it ensures stabilization of the forages and indicates better forage quality and feeding value of the fermented forage. As bale density increased, lactic acid, acetic acid and total acid percentages increased.

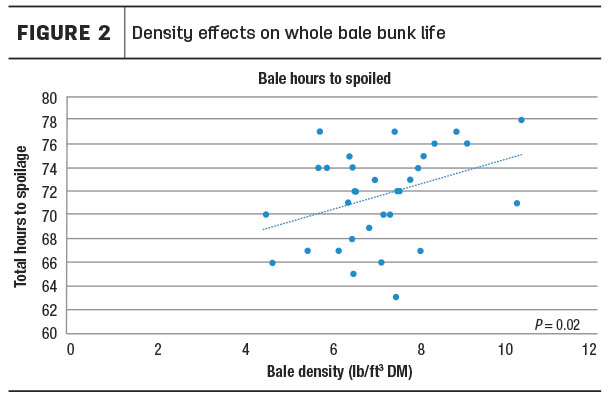

Whole bale bunk life is increased as density of the bale increases. A bale is considered spoiled when it reaches 2ºF above the baseline temperature of the bale. At the point of spoilage, it is no longer suitable for livestock consumption. Although variable, results indicate as density of the bale increases, the longer that forage can sit in a feeder without spoiling or becoming unfit for livestock to eat (Figure 2). This indicates that by increasing density of the bale, the feeding time also increases and rate of spoilage slows.

Conclusions

Best management practices for baleage production can ensure the highest-quality forage is being produced. By ensuring forage is harvested at the correct stage of maturity, baled at the correct moisture, wrapped quickly and baled at the maximum density setting on the baler, optimal forage quality can be achieved! Baling at the maximum density setting can help ensure proper fermentation of the baleage, improving feeding value and prolonging bunk life. ![]()

PHOTO: Moisture levels greater than 60 to 65 percent can result in spoilage and low palatability of forages, and moisture levels less than 40 to 45 percent can result in mold growth. Photo provided by Jessica Williamson.

Marvin Hall is a professor of forage management with Penn State Extension.

Acknowledgments: This study was funded by CNH Industrial; New Holland, Pennsylvania. A portion of this article was originally published in the Penn State Field Crop News and can be found at: Penn State Extension - research spotlight: bale density effects on baleage quality.

Jessica Williamson is a forage specialist at Penn State Extension. Email Jessica Williamson.