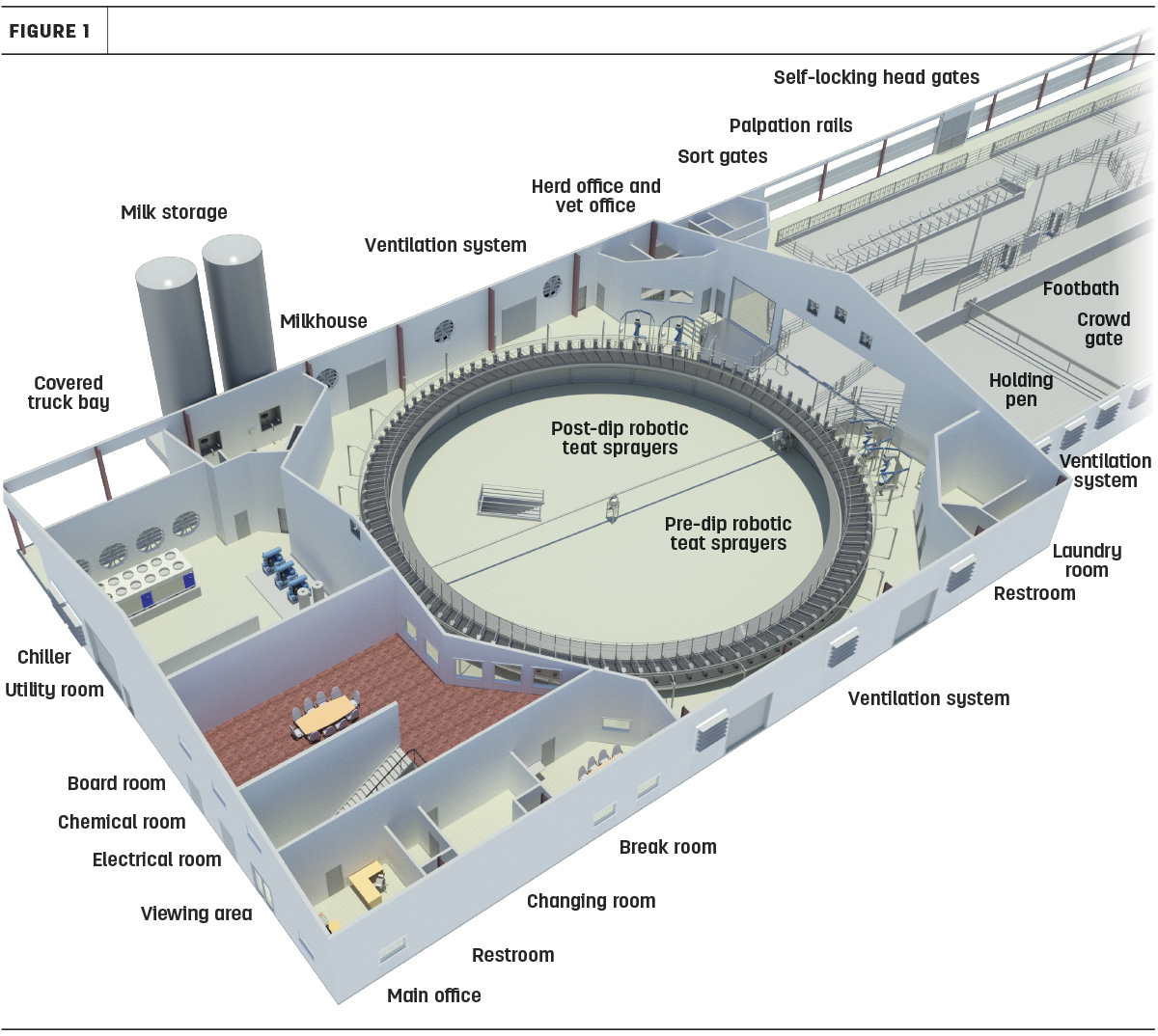

There are several design aspects to consider when planning a new rotary milking facility. Be sure to discuss the main ones with a professional rotary facility designer. Doing the research and planning before breaking ground will save you headaches and, most likely, money if last-minute changes are requested.

Main office

Located for easy access and security.

Break room

Big enough to accommodate employee meetings, trainings and team-building activities.

Changing room, break room, restrooms and viewing area

Locate these areas together so the environments can be controlled separately from the rest of the dairy facility.

Second-floor area

Rotary buildings are typically tall enough to add a second-floor area, which is more cost-effective than increasing the size of the structure to accommodate an office, board room or viewing area.

Utility room

There is a lot of equipment that needs to be placed in the utility room. Ensure there is adequate space to accommodate water storage, pumps, treatment and heating systems as well as water manifolds, which distribute water to the rest of the dairy facility. Additionally, air compressors, dryers and vacuum systems need to be incorporated in this space. The milk cooling system can also be included in this area or outside the structure. Keeping the chiller inside will protect it from the elements, and a proper ventilation system can be beneficial in reclaiming the generated heat in colder weather and dispersing it outside when it is hot.

Electrical room

An electrical room separate from the utility area will ensure a clean, dry environment for electrical equipment.

Chemical room

Storing the necessary chemicals in a separate, well-ventilated area contributes to a cleaner, non-corrosive environment in the rest of the utility area.

Milkhouse

There may be more equipment required in the milk room than what you may expect. Ensure the facility design has adequate space for each component.

Covered truck bay

A covered bay is not required everywhere, but it is a great option to consider.

Herd office and vet office

Locate these offices in close proximity to the exit area and the sort and handling area where stored supplies are needed and staff have easy access to and from working area.

Robotic teat sprayers

Pre- and post-dip robotic teat sprayers are a great way to reduce labor in the parlor, so be sure to incorporate enough space to include them during construction or in the future.

Laundry room

If towels are being used to clean cows, then locate the laundry facilities close by.

Holding pen

Ensure the holding pen is big enough to hold your largest group of cows behind the crowd gate when there is still approximately 25% of the previous group still waiting for their turn to enter the rotary.

Lighting

Incorporating some natural light is always recommended, but make sure to include adequate lighting to provide a bright, safe environment for everyone.

Ventilation

There are different ways to ventilate the parlor area depending on local climate and other considerations. Inviting fresh air to enter through the sidewalls and exit out into the holding pen and post-sort area is a great way to keep the milking area well-ventilated. Forcing warm air from the utility room is a great source of heat in colder weather.

Post-sort and handling area

There are many options to consider when designing a sort and handling area to fit everyone’s needs. Incorporating sort gates with multiple sort options is a great time-saver. Being able to separate cows into different areas where they can stand in a palpation rail or a lane with a headlock is a great option when staff is available to manage the cows and send them on their way. Group pens with locking headgates and access to feed and water or an area with beds where cows can lie for a period before they are moved to other locations are also great options.