To read this article in French, click here.

It is 3 o’clock in the afternoon, and the hay is just finally dry enough to bale. On the first round in the field, my pocket vibrates just as my radio sitting in the cup holders starts to blast; it must be bad news. The news is very bad – a neighbor’s hay barn has a slight smell of smoke, and temperature monitoring has found a hot spot. Two weeks ago, there was a fury in the area to finish baling as the National Weather Service forecast called for 2 inches of rain to start at 5 p.m. The relative humidity two days prior never fell below 80%. With these weather conditions, many producers in the area baled hay over 20% moisture, while acid-based preservatives were used on much of the hay. There were some wet spots that were still too wet or areas where the acid was not applied evenly.

Luckily, this producer was monitoring his hay barn, and this incidence did not result in a lost barn and all of its content. Monitoring of haystack temperature is a good idea any time hay is put in storage above 18% moisture. All hay over 15% moisture goes through a heating and sweating period, usually peaking in temperature between 125ºF-130ºF within three to seven days after baling with minimal risk of combustion or forage quality losses. After peak temperature is reached, hay generally returns to normal temperature over the next 15-60 days.

Assessing your risk

If hay was baled between 15%-20% moisture and acid preservatives were used, there is still potential for a hay fire, but not as great as on non-treated hay. Most propionic acid-based products are effective if applied at the correct rates at inhibiting bacteria growth in hay up to 25% moisture, with variable effectiveness at 25%-30% moisture. Some products have preservatives containing ethoxyquin or butylated hydroxytoluene and at temperatures of 240ºF or above, produce hydrogen cyanide gas, which is very deadly. Products that contain primarily propionic acid do not have this risk.

At over 20% moisture, mesophilic bacteria release heat, causing the temperature to rise between 130°F to 140ºF, with temperature staying high for up to 40 days. As temperatures rise, thermophilic bacteria can take off in your hay and raise temperatures into the fire danger zone of over 175°F.

When stacking high-moisture hay in barns, allowing for more ventilation and air flow around the bales decreases the risk of fire. This allows for natural cooling to help keep the temperatures lower, but in very wet hay also increases the oxygen available to fuel the fire. Occasionally, outside stacks or barn storage with a leaking roof can lead to wet hay that drives thermophilic bacterial growth and fire potential.

Monitoring the haystack

There are a couple of options available to monitor hay temperature. One of these is high technology, like the cables that can be used to monitor temperature in stored grain. There are a couple of companies that produce cables that would be placed between bales in a stack or monitoring probes placed in bales and use radio frequency to transmit signal.

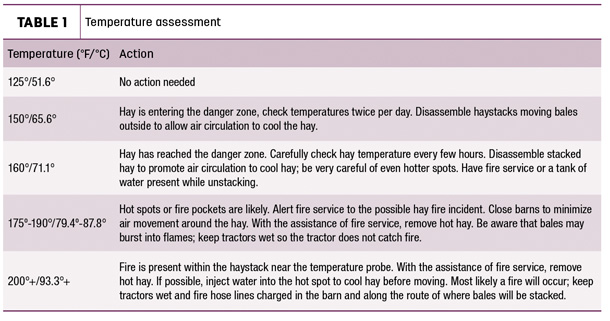

If you believe that you may be at risk for hay heating, monitoring temperature is critical. It should be done daily until temperatures stabilize in the safe zone or reach 150°F when monitoring needs increase to twice daily. This can be done with technology or manual temperature probes. When monitoring hay temperature, be very cautious; hot hay can burn within the stack and cause cavities underneath that you can fall into. Use planks to spread out your weight while walking on the stack and have a harness system attached to the ceiling in case you fall into a burned-out cavity. Also, work in pairs with someone on the ground within voice range to assist you if you find yourself in a bad situation. Temperature monitoring should continue for possibly six weeks until values stabilize in the safe zone.

Temperature monitoring depends on the stack size but should be taken close to the center of the stack. In larger stacks, ideally this is 8 feet down in the stack. This can be done by purchasing a long probe thermometer or building your own. This length of probe will be hard to push into the stack, so handles will be helpful. Building your own can be done with a 3/8-inch to 3/4-inch piece of pipe or electrical conduit cut into a closed point. The pipe size will depend on the thermometer probe size you will put in the pipe. A larger pipe can be used and a thermometer on a string lowered into the pipe. Drill 3/16-inch holes in the bottom 4 feet of the pipe. Leave the thermometer in the stack for about 10 minutes to get an accurate reading. A less accurate method is to leave a pipe in the stack all day, and if a section is too hot to hold in your hand when removed, you are at risk for fire. Any time temperatures are above 175ºF, hay should not be removed from the barn until the local fire department is present – you are at risk for fire. Once the fire department is present, hay should be carefully removed from the barn with charged fire hoses ready if spontaneous combustion occurs. Have a safe and well-drying hay season this year.