Erratic weather patterns across the U.S. have stressed many silage crops in the field. Some regions and forage crops have experienced prolonged high temperatures and drought. Other regions faced excess heat and humidity, along with localized and intense storms. The latter brought various combinations of wind, hail and heavy rain, leading to flooding.

Discussions between the farm team – the owner, herd manager, agronomist and nutritionist – are needed to assess which crops should be harvested and for what feeding purpose. Those deemed “salvage” should not be used for transition cows or highly productive milk cows. Those crops that can be considered “clean feed” are suitable for any class of productive animals.

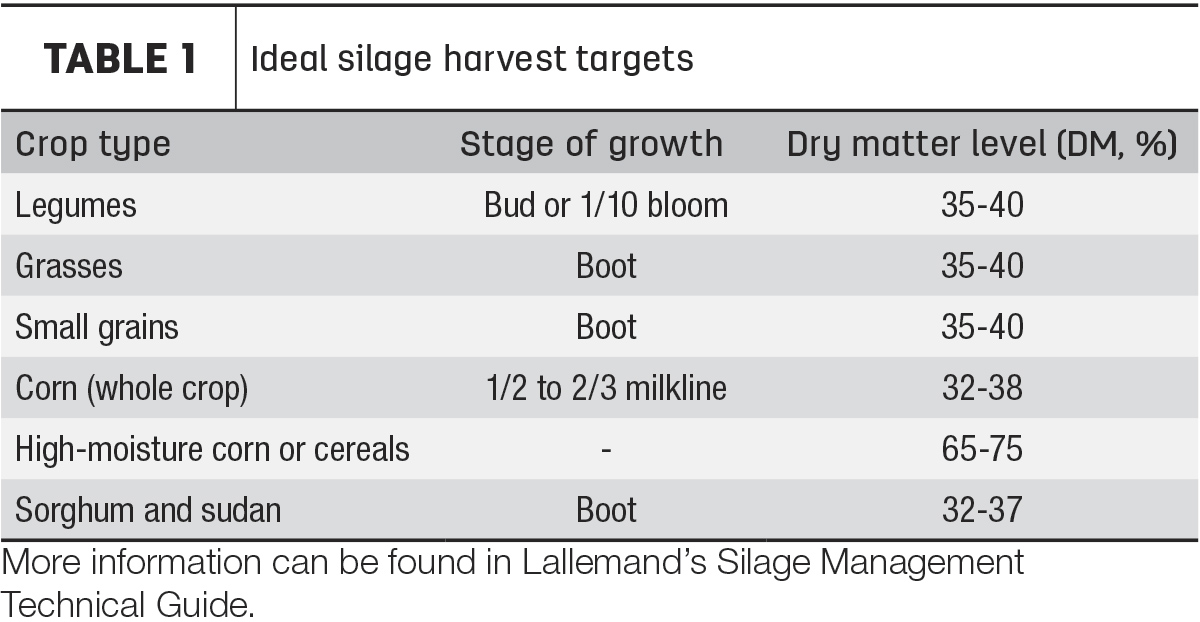

This article can serve as a guide to help get the most tonnage from the wide range of crops yet to be ensiled this year. Remember to target the right stage of growth at harvest and dry matter (DM) (see Table 1). Chopping and harvesting silage crops at lower DM (or more moisture) risk more seepage, nutrient loss and spoilage due to enterobacteria and clostridia activity. Crops at high DM levels are more difficult to pack effectively in the silo and are at higher risk of fungal spoilage, especially at feedout.

Drought-stressed crops

Assuming there is sufficient crop to harvest, there could be potentially toxic nitrate levels in the plants. Delaying harvest four to five days after a drought-ending rainfall allows the plants to metabolize some of the accumulated nitrate reserves. In whole-plant corn, a high proportion of the residual nitrate is in the lower third of the stalk, so higher cutting heights at chopping will significantly reduce nitrate in the harvested crop (12 to 18 inches off the ground). Of course, there is a trade-off with implementing that practice. With higher cutting heights, there is a reduction in yield and overall tonnage, and that will impact overall silage inventory. However, you will harvest the most valuable and nutrient-dense portions of the plant and have lower nitrate levels.

Drought-stressed crops tend to have lower levels of natural lactic acid bacteria (LAB), resulting in poor fermentation. The use of a research-proven homolactic lactic acid bacteria (hoLAB) inoculant applied at 100,000 colony forming units (CFUs) hoLAB per gram of fresh forage will ensure an efficient fermentation in drought-stressed crops. Pediococcus pentosaceus NCIMB 12455 is one specific strain of hoLAB that was originally selected from well-fermented silage and has been proven in trials and in on-farm forage challenges since its commercial introduction in the mid-1980s. In addition to reducing DM and nutrient losses, a hoLAB inoculant will help expedite a reduction in residual nitrate levels by up to 40%. Ideally, operations should leave the ensiled crop undisturbed in the pile or silo for a month or more, which will allow the nitrate reduction process to occur.

Prolonged drought also leads to higher fungal levels (molds and yeasts). This case would need a bacterial forage inoculant that can improve feedout and stability of the silage. A high-rate Lactobacillus buchneri 40788 inoculant is preferred, which would deliver 400,000 CFU per gram of forage coupled with 100,000 CFU of a hoLAB.

Make feed teams aware that high-nitrate-content crops can produce a dangerous silo gas – nitrogen dioxide (NO2). This gas is a yellow, dark-orange color, is heavier than air and smells like bleach. If present, it is especially common to appear in the few days of fermentation, in some cases up to 10 days after sealing. This gas is very toxic and extreme caution should be used; it can damage the mucous membranes (eyes, throat, lungs, etc.) of humans and livestock. If the silage must be fed within 10 days of ensiling and there is reason to suspect silo gases are present, consider the use of respirators.

Wind-damaged crops

A lot will depend on the stage of growth when the damage occurred, the severity of the damage and if harvest is feasible. With whole-plant corn, as long as there is no green snap (broken stalk or stem), the plant will try to grow back upright. This increases challenges during harvest. There is a risk of soil contamination with excessive winds, which will buffer against silage fermentation and the initial pH drop. Soil contamination can bring unwanted enterobacteria and clostridia – a recipe for potential fermentation disaster. Wind-damaged crops need an effective, proven hoLAB inoculant applied at 100,000 CFU per gram of forage. If the crop is drier than expected at harvest, a reduction in chop length is recommended to ensure better packing and consider investing in the hoLAB + LBuc inoculant combination, applied at a total count of 500,000 CFU per gram of forage.

Hail-damaged crops

Plant stage of growth, hail size, intensity and duration of the storm will all impact the extent of crop damage. Inspect the crop five days after the storm to assess the overall damage. Due to physical plant damage, these crops are prone to a wide range of fungal infections (fusarium, gibberella, aspergillus and spoilage yeast species are the common culprits), and dry matter throughout the field will vary. Follow good ensiling practices, including a research-backed hoLAB + LBuc combination inoculant at 500,000 CFU per gram of forage.

Flood-damaged crops

Flood-damaged crops present unique challenges – infestation with multiple undesirable microbial contaminants, such as enterobacteria, clostridia, listeria, bacillus, molds, spoilage yeasts and mycotoxins. In addition, there will be silt and soil contamination in the lower parts of the plant, which increases the buffering capacity in the ensiled forage mass and higher ash levels at testing. The silt is the initial vector for microbial contamination and may lead to an array of fungal diseases not normally seen in healthy whole-plant corn. The high ash levels will also reduce the energy level of the crop, may contain very high amounts of antagonistic trace elements – such as iron (Fe) and aluminum (Al), among others – and be abrasive along the animal digestive tract.

The farm team should agree on which acres can be safely and usefully harvested. This will depend on these four criteria:

- When the flooding occurred

- The amount of silt contamination within and on the crop

- The overall look of the crop

- Whether ground conditions have improved enough for the harvest equipment to get in and out safely

It is recommended to harvest at the proper DM (Table 1) and to harvest whole-plant corn higher to leave the high ash and silt-contaminated stalk base in the field (12 to 18 inches off the ground). If possible, ensile this crop in a separate bag, bunk or silo. This will be one of the most contaminated and difficult crops to ensile successfully. It demands an effective and proven hoLAB + LBuc combination inoculant at 500,000 CFU per gram of forage.

Do not cut corners on sample analyses before feeding this material. If the analyses identify any problems, avoid feeding to transition cows. Feeding inclusion rates may also need to be lower than usual for other cow pens; dilution can be part of the solution for compromised silages that have to be fed. When introducing compromised silage in the ration, watch for cow pen responses in DM intake, milk or component yields, higher somatic cell counts, or unusual fecal texture and variations.

Implementing your plan

Summer weather patterns have led to unusual and stressful crop growing conditions before, and right up to, harvest dates. With care, an engaged farm team can navigate the potential pitfalls to make a wide range of usable silages. Here are five easy things to do to set your operation up for success:

- Meet with all key farm team members to create a harvest plan tailored to your specific weather-related growing challenges.

- Use research-proven and effective hoLAB and LBuc combination forage inoculants at the correct application rates. Forage inoculants can help ensure a successful ensiling fermentation and great stability and shelf life during feedout.

- Be safe. Harvest is fast and there are a lot of different people who might not normally be present on your operation. When dealing with drought-challenged crops, be aware of the potential for noxious silage gases. Please exercise extreme caution and wear respirators.

- Analyze your silage often. A comprehensive near-infrared (NIR) test is required to properly assess the nutrients available with each silage. Depending on your specific weather-related growing challenges, these additional analyses might be prudent: wet chemistry analysis, nitrate content, mold and yeast counts, mycotoxin screening, and mineral and trace element analysis.

- Adjust your rations and monitor the cows. Your nutritionist will make ration adjustments specific to your silage analysis results and inventories. Including probiotic feed additives will be helpful when feeding compromised silages and maintaining animal health and performance. The cows will tell you how successful your management and feeding adjustments are through observations of intake, behavior, health and performance levels.

Now is the time to set your operation up for a successful and safe silage harvest, even when Mother Nature might not have cooperated.

References omitted but are available upon request by sending an email to the editor.