To read this article in French, click here.

Fermentation is loosely defined as the extraction of energy from carbohydrates in the absence of oxygen (anaerobic). Natural fermentation happens in all aspects of nature and even in the gastrointestinal tracts of animals and humans. In silage, there is fermentation to the point of acidification and then stability, which reduces the pH and then reduces and excludes negative molds and fungi development.

Silage fermentation has its roots back to Egypt in 2,000 B.C. and has been seen in many cultures over time. From the 1850s to the 1860s, Louis Pasteur’s work showed that lactic acid is produced by living organisms. In 1877, French agriculturalist Auguste Goffart wrote a book titled The Ensilage Of Maize, And Other Green Fodder Crops. Then, in 1879, Maryland farmer Francis Morris successfully accomplished silage fermentation, and silage production has blossomed from then.

Know your numbers

When we receive a forage sample, we first look at individual numbers such as dry matter, crude protein (CP), neutral detergent fiber (NDF), starch, relative feed value (RFV), relative feed quality (RFQ) and milk per ton. We are beginning to monitor fiber pools and digestibility numbers, but we often overlook the fermentation values unless there is an issue.

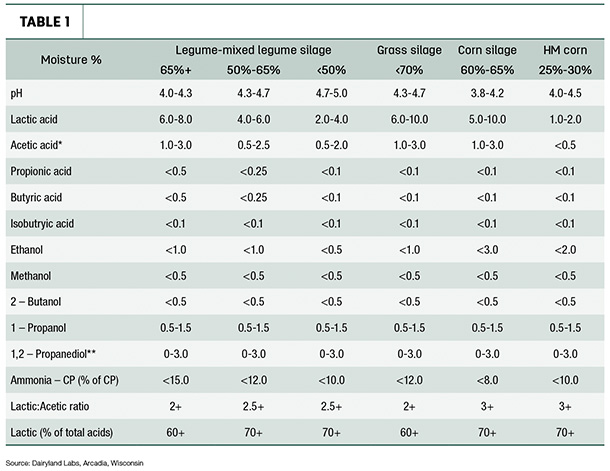

Most forage samples show pH, lactic acid, acetic acid, propionic acid, butyric acid, 1,2 propanediol, total volatile fatty acids, lactic-to-acetic ratio and lactic acid as a percent of total volatile fatty acids (VFAs). Benchmarks (Table 1) are a great guide to follow and to strive for.

Traditionally, pH was looked at as the measure of fermentation. For haylages, the goal is to have the pH less than 4.7 – and for corn silage, the goal is to be less than 4.0. Depending on forage type, lactic acid is a number where quality of fermentation is routinely gauged. We can monitor how lactic acid fares as a percent of all the VFAs. Typically, the goal is to have lactic acid greater than 60% to 70% of total VFAs. Also, another good number to look at is the ratio of lactic acid to acetic acid, as this is typically 2 or 3 to 1.

Monitoring the total acids is another great metric to monitor how the forages fermented. The range for the acids combined should be 7% to 9% total acids. Further evaluate how the forage fermented if the total acid levels are greater than 10% and lower than 5%, as both ends of the spectrum can be problematic. Too little total organic acid levels are often seen in fall-harvested haylage crops or drier baleage fermentations. Often, this is caused by lower sugar levels or low moisture levels in the forage. When the total acids are above 10%, the forage will be wet, and improper or slow fermentation has occurred. Typically, acetic acid and butyric acid will have surged and dominated this poor clostridial fermentation. There are also more in-depth fermentation metrics that involve ethanols, alcohols, ammonia and biogenic amines.

Keys to fermentation

- Reduction of oxygen

- Adequate sugar levels and carbohydrates to promote bacterial activity

- Appropriate composition, temperature and suitable numbers of microbial bacteria

- Proper harvest moisture

Moisture is key

Harvest moisture is at the heart of a proper fermentation. Many factors impact the correct harvest moisture range, but forage type is very critical in the process of fermentation. Legumes, with their high buffering capacity, high mineral content, often higher ash content and marginal sugar content, create a struggle between pH and correct bacterial media. The goal for legumes for final pH is below 4.7. If the fermented legume forage pH is above 4.7, we should troubleshoot to identify whether it was a moisture issue, a speed of packing and oxygen reduction issue or a sugar and adequate bacterial load situation.

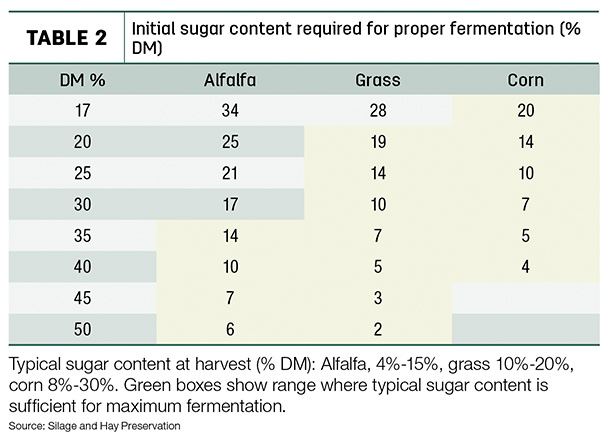

Often, legumes will ferment best at a moisture below 60% to 65%, due to their buffering capacity. Cereal grain silages, grass silages, mixed silages and corn silage can handle a broad range of moisture due to their higher sugar and carbohydrate content. Corn silage also has its fermentation limits, as greater than 70% moisture will often elicit acetic acid and have a vinegar smell, as well as a yellow appearance. We see that often at the bottom 2 feet of bunker silos and piles. The challenges of corn silage less than 60% moisture are universally understood. Fermentation challenges, yeast and mold growth can derail corn silage fermentation value and make aerobic stability a challenge. Table 2 describes the dry matter at harvest to the sugar content of various forage types.

This is a great example of why harvest dry matter is so critical and the best investment with inoculants is often on haylages. Grasses and corn silage have the potential capability to be harvested at a higher moisture, due to their sugar and carbohydrate content at harvest. There is no guarantee because the sugar level and epiphytic bacteria load are not known, as there are many dynamics such as ash content, moisture content, maturity of forage and, chiefly, sunlight.

Lactic acid is king

As corn silage is the king of forages, lactic acid is the king of fermentation. The simplest form of fermentation is a homolactic fermentation; this results in a fast fermentation after the exclusion of oxygen. Lactic acid production, is created generally from both natural forms of lactobacillus and in many commercial inoculants using Lactobacillus plantarum. These “front-end” fermenters have been the backbone used in many silage inoculants over the years and are a great way to help epiphytic (natural) bacteria reduce the pH in an anaerobic (without oxygen) situation very quickly and efficiently. This reduction of pH will inhibit fungal and yeast growth. Lactic acid is a strong acid, which will lower the pH quickly and is utilized in the rumen as another form of fuel for the rumen bacteria.

Acetic acid

While lactic acid is a strong organic acid, acetic acid is a great preservative but a weak acid. Native acetic acid is often produced in situations of slower fermentation, due to either high moisture at harvest or, conversely, low moisture at harvest. Another situation commonly found in corn silage is the slow fermentation from filling a bunk over multiple weeks. This often results in equal acetic acid to lactic acid levels, which is indicative of a slower, reduced fermentation and leads to dry matter loss in the bunk.

Commonly, heterofermentative is a slower form of fermentation that results in some lactic acid production but also other forms of organic acid production, such as acetic acid. There can be a benefit of a heterofermentative fermentation with specific strains of Lactobacillus buchneri. Through a slower fermentation that can take several weeks, the Lactobacillus buchneri will convert lactic acid to acetic acid, which will assist in situations where bunk preservation is an issue. This preservation can be vital in large corn silage bunk faces, slow feedout and high-moisture corn. The conversion of lactic acid to acetic acid will reduce yeast growth and aerobic deterioration.

Butyric acid

Butyric acid is another organic acid that is a byproduct of improper fermentation. Typically caused by slow fermentation at a high moisture, butyric acid will increase over time and is identified by its pungent smell that will often be worn to the house – and one the farm dog tends to roll around in. Butyric acid is highly responsible for reduced dry matter, feed quality and energy. Often, butyric acid at high levels can increase propensity for ketosis in fresh cows. Many times, high levels of butyric acid will be associated with wet feeds, manure-contaminated feeds at any dry matter, higher-ash feeds, clostridial feeds, low lactic acid production, higher pH, low sugar content, biogenic amines and increased ammonia.

Summary

Fermentation is such a vast topic, and it is difficult to give it justice within one article and in one sitting. The main questions most producers have regarding fermentation are dry matter loss and forage stability. The reduction of dry matter loss has many twists and turns, from harvest management, bunk management and proper fermentation. The harvest moisture, depending on forage type, certainly is one of the main factors that affect fermentation.

The use of proven inoculants has a long history of return on investment, even if it is sometimes difficult to visually assess. Haylages and cereal grain silages will benefit from that inoculant boost of added homofermentative bacteria. Inoculant for corn silage is a more difficult subject, given its propensity to rapidly reduce its pH. With factors such as variation in harvest moisture, preservation at feedout and inoculant combinations with Lactobacillus buchneri, the need for inoculants in corn silage become more apparent. As margins decrease and inputs continually rise, forage quality is at its most important point in the dairy industry. Fermentation is a large piece of that profitability puzzle that must be solved.